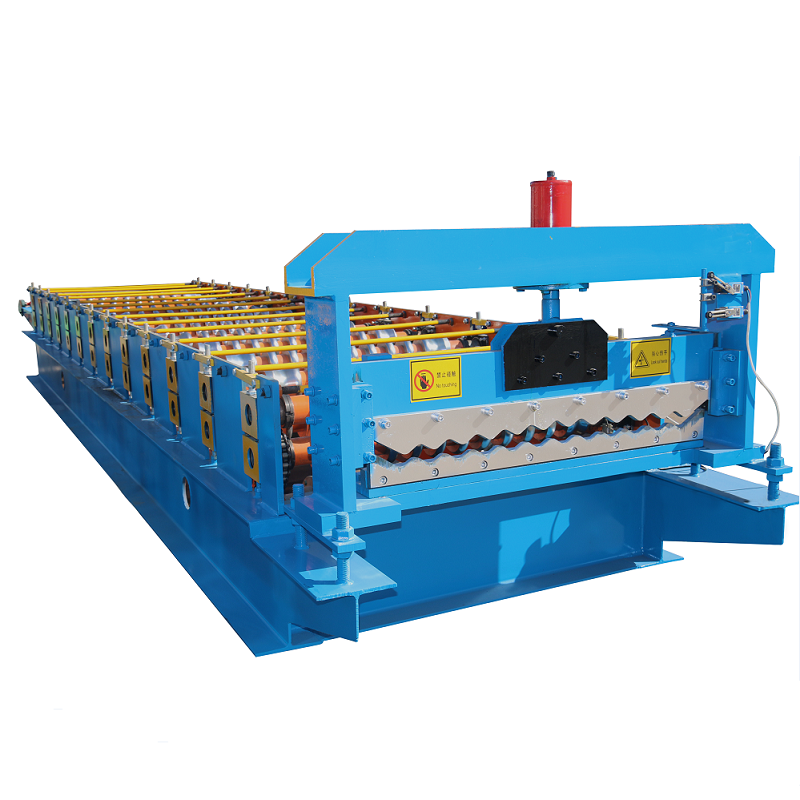

High-Quality Color Steel Roll Forming Machine for General Purpose Industrial Use

By:Admin

The GP GI Color Steel Roll Forming Machine is the result of years of research and development by the company, which has a proven track record of delivering high-quality and reliable manufacturing solutions. With a focus on innovation and technological advancement, the company has positioned itself as a leader in the industry, continuously striving to push the boundaries of what is possible in steel production.

The demand for color steel products, such as roofing and wall cladding materials, has been steadily increasing in recent years. This can be attributed to the growing construction industry, as well as the rising popularity of sustainable and aesthetically pleasing building materials. As a result, manufacturers are constantly seeking ways to improve their production processes to keep up with the market demand.

The GP GI Color Steel Roll Forming Machine is set to address these industry challenges by offering a range of advanced features that set it apart from traditional roll forming machines. Equipped with cutting-edge technology, the machine is capable of producing high-quality color steel products with exceptional precision and efficiency. This is made possible by its innovative design, which incorporates the latest advancements in automation, material handling, and quality control.

One of the key advantages of the GP GI Color Steel Roll Forming Machine is its ability to streamline the production process, thereby reducing lead times and increasing output. This is achieved through its high-speed forming capabilities, coupled with its intelligent control system that optimizes the manufacturing process. Additionally, the machine is designed to minimize material wastage, ensuring that manufacturers can maximize their resources while minimizing costs.

Furthermore, the GP GI Color Steel Roll Forming Machine is highly adaptable, capable of producing a wide range of color steel products with different specifications and designs. This versatility is a significant advantage for manufacturers who need to meet diverse customer requirements, allowing them to quickly switch between product variations without the need for extensive retooling.

In addition to its technical capabilities, the GP GI Color Steel Roll Forming Machine also prioritizes operator safety and ease of use. It is equipped with advanced safety features and user-friendly interfaces, ensuring that operators can work efficiently and without unnecessary risks. This not only improves the overall working environment but also contributes to consistent and reliable production outputs.

The introduction of the GP GI Color Steel Roll Forming Machine is a testament to the company's commitment to driving innovation and excellence in the steel manufacturing industry. By leveraging its expertise and technological capabilities, the company has developed a machine that is set to redefine the standards of quality and efficiency in color steel production.

As the global demand for color steel products continues to grow, the GP GI Color Steel Roll Forming Machine is poised to become an indispensable asset for manufacturers looking to stay ahead of the competition. With its combination of cutting-edge technology, versatility, and user-centric design, this machine is set to make a significant impact on the industry, setting new benchmarks for productivity and performance.

Company News & Blog

Ultimate Guide to Color Steel Roll Forming Machines: Essential Insights and Tips

Title: Revolutionary Color Steel Roll Forming Machine Revolutionizes Manufacturing Industry Introduction: In today's rapidly evolving manufacturing industry, a new and innovative solution has emerged in the form of a state-of-the-art Color Steel Roll Forming Machine. Designed with cutting-edge technology and engineered for efficiency, this groundbreaking machine has the potential to revolutionize the way steel is processed and transformed into various construction materials. With its streamlined operation and remarkable output capabilities, the Color Steel Roll Forming Machine (brand name to be removed) promises to reshape the industry landscape, setting new standards for productivity and precision.Innovative Features:The Color Steel Roll Forming Machine incorporates a range of innovative features that elevate its performance and efficiency. One of its key advantages is its ability to process steel sheets seamlessly, forming them into precise shapes with exceptional precision. The machine's advanced computer-controlled system ensures consistent output, reducing the margin of errors, and improving the overall product quality.Additionally, the Color Steel Roll Forming Machine is equipped with a highly efficient material feeding system, enabling a continuous flow of steel sheets into the machine. This eliminates unnecessary downtime and maximizes productivity, providing a significant advantage to manufacturers seeking seamless, uninterrupted production.Furthermore, the machine's automatic cutting system ensures accurate and clean cuts, eliminating the need for additional post-processing. This not only saves time but also reduces material wastage, making it an environmentally conscious choice for manufacturers worldwide.Unmatched Versatility:The Color Steel Roll Forming Machine boasts unparalleled versatility, capable of producing an extensive range of architectural steel products. From roofing panels and wall claddings to steel trusses and structural profiles, this machine accommodates diverse market demands with ease. Manufacturers can swiftly switch between product specifications, effortlessly adapting to evolving customer needs, and market trends.Energy Efficiency:As the manufacturing industry continues to prioritize sustainable practices, the Color Steel Roll Forming Machine stands out for its eco-friendly design. By utilizing advanced energy-saving technologies, it minimizes power consumption without compromising production efficiency. With reduced energy costs and carbon footprints, manufacturers using this machine contribute towards a greener future for the industry.Automation and Ease of Use:Designed with user-friendliness in mind, the Color Steel Roll Forming Machine empowers both experienced professionals and newcomers in the manufacturing industry. With its intuitive interface and integrated automation capabilities, operators can easily program and adjust settings, ensuring optimal performance and quick setup times. This minimizes the need for highly skilled labor and reduces training costs, making it an attractive investment for manufacturers of all scales.Market Impact:The introduction of the Color Steel Roll Forming Machine is expected to leave a lasting impact on the manufacturing industry. Its ability to streamline production processes, improve product consistency, and increase overall efficiency redefines the standards for steel processing. With reduced operational costs and enhanced product quality, manufacturers can gain a competitive edge in the market, meet rising customer expectations, and expand their market share.Conclusion:The Color Steel Roll Forming Machine, with its advanced features, unrivaled versatility, and eco-conscious design, represents a major breakthrough in the manufacturing industry. By utilizing innovative technologies and automation, it optimizes production processes and offers significant benefits to businesses across the sector. As manufacturers embrace this groundbreaking machine, they will pave the way for a more sustainable and efficient future, revolutionizing the industry as a whole.

Steel Solar Mounting Structure Roll Forming Machine: The Latest in Solar Technology

Color Steel Solar Mounting Structure Roll Forming Machine Revolutionizing Renewable Energy IndustryIn the ever-evolving world of renewable energy, the demand for efficient and cost-effective solutions is continuously on the rise. One company is at the forefront of this revolution, providing cutting-edge solutions for the solar energy industry. With a focus on innovation and quality, they have recently launched their state-of-the-art Color Steel Solar Mounting Structure Roll Forming Machine, which is set to transform the way solar mounting structures are manufactured.The Color Steel Solar Mounting Structure Roll Forming Machine is a game-changer in the industry, providing a streamlined and efficient process for producing high-quality mounting structures for solar panels. With its advanced technology and precision engineering, this machine is capable of producing a wide range of mounting structures with unparalleled accuracy and speed.One of the key features of this revolutionary machine is its versatility. It can be customized to meet the specific requirements of different solar projects, allowing for a seamless integration with various types of solar panels and installation environments. This flexibility is crucial in the rapidly evolving solar industry, where each project comes with its own unique set of challenges and requirements.In addition to its versatility, the Color Steel Solar Mounting Structure Roll Forming Machine also boasts a high level of efficiency. Its automated processes and advanced production capabilities result in significant time and cost savings, making it an ideal solution for both large-scale commercial projects and smaller residential installations. This efficiency is a major selling point for solar developers and installers, who are constantly looking for ways to optimize their production processes and maximize their returns.Furthermore, the machine is designed with sustainability in mind. By utilizing eco-friendly materials and energy-efficient processes, it aligns with the company's commitment to environmental responsibility. This becomes increasingly important as the world looks towards renewable energy as a key solution in combating climate change and reducing our reliance on fossil fuels.The successful launch of the Color Steel Solar Mounting Structure Roll Forming Machine is a testament to the company's dedication to innovation and excellence. With a track record of delivering high-quality products and solutions to the solar industry, they have established themselves as a trusted partner for solar developers and installers around the world.Their commitment to customer satisfaction is reflected in their comprehensive support and service offerings. From initial consultation and design to installation and maintenance, they provide end-to-end assistance to ensure the success of their clients' projects. This level of dedication has earned them a loyal customer base and a stellar reputation within the industry.Looking ahead, the company is focused on further advancements in solar technology, with a keen eye on the latest industry trends and developments. They are constantly exploring new ways to improve their products and processes, with the goal of staying at the forefront of the ever-changing renewable energy landscape.As the demand for solar energy continues to grow, the need for reliable and efficient mounting structures will only increase. The Color Steel Solar Mounting Structure Roll Forming Machine is set to play a pivotal role in meeting this demand, providing a cutting-edge solution for the solar industry's mounting structure needs.In conclusion, the launch of the Color Steel Solar Mounting Structure Roll Forming Machine represents a significant milestone in the renewable energy industry. With its advanced technology, versatility, efficiency, and sustainability, it is poised to revolutionize the way solar mounting structures are manufactured. As the industry continues to evolve, this innovative machine is well-positioned to meet the growing demands for reliable and cost-effective solutions in the solar energy sector.

Metal Glazed Tile Roll Forming Machine for Colorful Roofing Sheets

and Glazed Tile Roll Forming Machine.Colored Metal Steel Sheet Roll Forming Machine and Glazed Tile Roll Forming MachineColored Roofing Steel Sheet Metal Glazed Tiles Forming Machine Roll Forming Machinery is a great investment for builders and contractors that specialize in roofing projects. This type of machinery is ideal for those who are looking for a cost-effective and efficient way to form roofing sheets and tiles.The Colored Metal Steel Sheet Roll Forming Machine and the Glazed Tile Roll Forming Machine are two types of machines that are commonly used in the roofing industry. These machines are designed to manufacture roofing sheets and tiles in different shapes and sizes, depending on the project requirements.The Colored Metal Steel Sheet Roll Forming Machine is a versatile piece of machinery that is used to form roofing sheets in various colors. The machine is designed to produce roofing sheets in a range of thicknesses, and it can be programmed to produce sheets in different lengths as well.The Glazed Tile Roll Forming Machine is another popular machine that is used in the roofing industry. This machine is specifically designed to produce glazed roofing tiles that are used for aesthetic purposes. The Glazed Tile Roll Forming Machine is ideal for builders and contractors who want to offer their clients a wide range of tile designs and colors.Both the Colored Metal Steel Sheet Roll Forming Machine and the Glazed Tile Roll Forming Machine are designed to offer high production rates and efficiency. These machines are user-friendly and require minimal maintenance. They are also designed to operate quietly, which is ideal for roofing projects that occur in residential areas.One of the biggest advantages of using a Colored Metal Steel Sheet Roll Forming Machine and a Glazed Tile Roll Forming Machine is the reduction of labor costs. These machines are designed to automate the process of forming roofing sheets and tiles, which eliminates the need for manual labor. This results in cost savings for builders and contractors, which can be passed on to their customers.When shopping for a Colored Metal Steel Sheet Roll Forming Machine or a Glazed Tile Roll Forming Machine, it is important to consider the material being used, the thickness of the material, the desired length and width of the roofing sheets or tiles, and the features of the machine. Different machines offer different features, such as adjustable forming speeds and customizable designs.In conclusion, the Colored Metal Steel Sheet Roll Forming Machine and the Glazed Tile Roll Forming Machine are two valuable pieces of machinery for builders and contractors in the roofing industry. They offer high production rates, efficiency, and cost savings. When investing in these machines, it is important to consider the needs and requirements of the project, as well as the features and capabilities of the machine.

Roll Forming Machine for Color Steel Production

Title: Advanced Color Steel Roll Forming Machine Revolutionizes the Steel Manufacturing IndustryIntroduction:With an ever-increasing demand for high-quality and sustainable construction materials, the global steel manufacturing industry has witnessed a significant technological advancement. The latest state-of-the-art Color Steel Roll Forming Machine has emerged as a game-changer, enabling efficient and precision-based production of color steel rolls.This groundbreaking technology, developed by a pioneering company committed to innovation and excellence in steel manufacturing, promises to revolutionize the industry. Designed to streamline the production process while reducing costs and enhancing product quality, this advanced roll forming machine is set to reshape the construction landscape.Streamlined Production Process:The Color Steel Roll Forming Machine automates and streamlines the manufacturing process for color steel rolls. It eliminates the need for manual labor, increasing both efficiency and productivity. With its fully automated operation, the machine can consistently produce high-quality, dimensionally accurate steel rolls at a significantly faster rate than traditional methods.Furthermore, this cutting-edge machine incorporates various advanced features such as automatic feeding, precision cutting, and accurate bending, ensuring a flawless end product. Additionally, it offers enhanced flexibility, allowing manufacturers to produce different profiles and sizes of color steel rolls as per customized requirements.Cost Efficiency and Reduced Waste:The Color Steel Roll Forming Machine is equipped with highly efficient energy-saving technologies. By optimizing power consumption and reducing material waste, it offers significant cost savings for manufacturers. The machine's ability to minimize production errors and material wastage ensures that each roll is utilized efficiently, thereby reducing overall expenses.Moreover, the advanced control system in the machine enables real-time monitoring and adjustment of production parameters. This not only enhances operational efficiency but also minimizes the need for manual intervention, further reducing labor costs.Environmental Sustainability:In line with the growing global focus on sustainability, the Color Steel Roll Forming Machine contributes to environmentally friendly manufacturing practices. Its energy-efficient design reduces carbon emissions and lowers the overall environmental footprint of the manufacturing process.Additionally, the machine's high precision and quality control mechanism ensure minimal material wastage, promoting sustainable resource management. By adopting this advanced technology, steel manufacturers can significantly reduce their impact on the environment and contribute to a greener future.Implications for the Steel Manufacturing Industry:The advent of the Color Steel Roll Forming Machine heralds a new era in the steel manufacturing industry. Its introduction is expected to bring about a multitude of benefits for manufacturers, contractors, and end-users alike.For manufacturers, the integration of this advanced technology allows for increased production capacity and reduced operational costs. The ability to produce a wide range of steel roll profiles opens up new market opportunities, catering to diverse customer demands.Contractors and construction firms benefit from the enhanced quality, precision, and efficiency of color steel rolls. These rolls, produced using the roll forming machine, exhibit superior durability, resistance to corrosion, and aesthetic appeal. The higher strength and reduced maintenance of color steel rolls significantly contribute to the longevity and sustainability of construction projects.Conclusion:The Color Steel Roll Forming Machine, developed by a leading company in steel manufacturing, represents a revolutionary leap forward in the industry. Its automated and efficient production process, coupled with cost-saving measures and environmental sustainability aspects, makes it the perfect solution for the evolving construction landscape.As more manufacturers integrate this advanced technology into their production lines, the steel manufacturing industry is poised to witness unparalleled growth and progress. The Color Steel Roll Forming Machine paves the way for a future where high-quality, sustainable, and economically viable construction materials become the norm, supporting the ever-growing infrastructure needs of our global society.

Creating Strong and Durable Components with Color Steel Profile Forming Technology

Title: Innovative Color Steel Profile Forming Equipment Revolutionizes Building and Construction IndustryIntroduction:[Company Name], a leading global manufacturer of cutting-edge industrial equipment, proudly introduces its latest innovation in the field of color steel profile forming. Developed after years of research and development, this state-of-the-art equipment promises to revolutionize the building and construction industry with its advanced features, unmatched quality, and exceptional precision.Paragraph 1:The new color steel profile forming equipment encompasses cutting-edge technologies to meet the increasing demand for durable, aesthetically pleasing, and energy-efficient building materials. This equipment streamlines the traditional manufacturing process, reducing labor costs and optimizing production efficiency. By combining [Company Name's] industry expertise and extensive experience, this revolutionary solution is set to transform the way buildings are constructed.Paragraph 2:Offering unparalleled versatility, the color steel profile forming equipment is capable of producing profiles in a wide range of dimensions and shapes. With its seamless integration into existing production lines, manufacturers can easily adapt to varying project requirements, allowing for swift and efficient customization of products. This flexibility gives architects and construction companies freedom in designing unique and visually appealing structures, while meeting the highest industry standards.Paragraph 3:The precision and accuracy of the color steel profile forming equipment are second to none. Equipped with advanced software and intelligent controls, every step of the manufacturing process is meticulously monitored, ensuring impeccable quality and consistency. The equipment is designed to minimize material waste, greatly enhancing cost-effectiveness, while maintaining superior structural integrity. These characteristics make it an ideal choice for large-scale commercial projects as well as residential constructions.Paragraph 4:Incorporating cutting-edge safety features, the color steel profile forming equipment prioritizes the well-being of operators and workers. The machinery is equipped with state-of-the-art sensors and emergency stop systems to prevent accidents and enhance workplace safety. Moreover, the user-friendly interface and intuitive controls make operating the equipment effortless, reducing the risk of error and improving overall efficiency.Paragraph 5:The advent of the color steel profile forming equipment aligns with the growing demand for environmentally friendly and sustainable construction practices. By utilizing high-quality raw materials and minimizing waste during production, this equipment significantly reduces the carbon footprint associated with conventional building methods. Moreover, the durability and longevity of the profiles produced using this equipment ensure reduced maintenance and replacement costs throughout the lifespan of the structures.Paragraph 6:[Company Name] remains committed to delivering exceptional after-sales support to its customers. A dedicated team of engineers and technicians is available to provide 24/7 technical assistance, addressing any queries or concerns promptly. Additionally, the company offers comprehensive training programs ensuring operators are well-equipped to harness the full potential of the color steel profile forming equipment.Conclusion:In summary, [Company Name's] groundbreaking color steel profile forming equipment is set to transform the building and construction industry, offering unparalleled versatility, exceptional precision, and advanced safety features. With its commitment to sustainability and customer support, the company is revolutionizing the way structures are built and providing architects and construction firms with the tools to create groundbreaking designs. The introduction of this innovative equipment marks a significant milestone in the evolution of the industry, driving it towards a more sustainable and efficient future.

Ultimate Guide to Color Steel Roll Forming Machine: Everything You Need to Know

Color Steel Roll Forming Machine is one of the crucial equipment used in the production of color coated steel sheets and panels. It is designed to efficiently and accurately bend and shape the steel, resulting in high-quality finished products. With the growing demand for color steel products in various industries such as construction, automotive, and furniture, the need for reliable and efficient roll forming machines has become essential.{Company name}, a leading manufacturer of roll forming machines, has been providing innovative and high-performance solutions for the metal forming industry for over a decade. Their expertise in designing and manufacturing roll forming equipment has made them a trusted partner for businesses looking to enhance their production capabilities.The Color Steel Roll Forming Machine offered by {Company name} is equipped with advanced features that ensure precision, speed, and durability. The machine is capable of processing different types of steel, including galvanized steel, pre-painted steel, and aluminum. This versatility allows manufacturers to produce a wide range of color steel products to meet the diverse needs of their customers.One of the key highlights of {Company name}'s Color Steel Roll Forming Machine is its user-friendly interface and automation capabilities. The machine is designed to be easy to operate, reducing the need for extensive training and minimizing the potential for errors. Additionally, the automation features enable seamless integration with other production processes, optimizing overall efficiency and productivity.Furthermore, the roll forming machine is built with robust materials and components, ensuring long-term reliability and minimal downtime. This commitment to quality and durability reflects {Company name}'s dedication to delivering equipment that meets the rigorous demands of modern manufacturing environments.In addition to the machine itself, {Company name} offers comprehensive support services to assist customers in maximizing the performance of their Color Steel Roll Forming Machine. This includes installation, training, maintenance, and technical assistance, providing a complete solution for businesses looking to invest in a reliable roll forming system.When asked about the significance of the Color Steel Roll Forming Machine for their customers, {Company name}'s spokesperson highlighted the impact on production efficiency and product quality. "Our roll forming machines are designed to streamline the production process and deliver consistent, high-quality results. By investing in our equipment, businesses can significantly improve their manufacturing capabilities and stay ahead in a highly competitive market."The growing popularity of color steel products in various industries, coupled with the increasing demand for efficient and reliable production equipment, underscores the importance of investing in a high-quality roll forming machine. {Company name} recognizes the evolving needs of their customers and continues to innovate their product offerings to support the growth and success of businesses in the metal forming industry.As a trusted partner for roll forming solutions, {Company name} remains committed to delivering cutting-edge equipment, unparalleled support, and ongoing value for their customers. With the Color Steel Roll Forming Machine, businesses can enhance their production capabilities, expand their product offerings, and ultimately achieve greater success in today's competitive marketplace.

High-Quality Steel Roofing Roll Forming Machine for Sale - Find Out More!

Color Steel Roofing Roll Forming Machine Revolutionizes the Roofing IndustryWith the advancement in technology, the roofing industry has witnessed a significant transformation. One of the most notable changes is the introduction of the Color Steel Roofing Roll Forming Machine by a leading company in the manufacturing industry. This innovative machine has revolutionized the way roofing materials are produced and has set new standards for efficiency, quality, and cost-effectiveness.The Color Steel Roofing Roll Forming Machine is designed to produce high-quality roofing materials using color-coated steel coils. The machine is equipped with advanced technology that allows for precise and efficient roll forming, resulting in perfectly shaped and dimensionally accurate roofing panels. This eliminates the need for manual labor and reduces the margin of error, ensuring consistent quality in every roofing material produced.One of the key features of the Color Steel Roofing Roll Forming Machine is its versatility. The machine can be adjusted to produce a variety of roofing profiles and sizes, making it suitable for different applications and architectural designs. This flexibility makes it an ideal choice for roofing contractors, builders, and construction companies who require diverse roofing materials to meet the demands of their projects.Furthermore, the Color Steel Roofing Roll Forming Machine is equipped with an automated control system that allows for easy operation and monitoring. This reduces the need for skilled labor and enhances productivity, leading to faster turnaround times and increased production capacity. The machine also boasts a high-speed forming process, enabling manufacturers to meet tight deadlines and fulfill large orders with ease.In addition to its efficiency and versatility, the Color Steel Roofing Roll Forming Machine is known for its cost-effectiveness. By automating the roll forming process, the machine helps companies minimize labor costs and material waste. This, in turn, results in higher profit margins and competitive pricing for customers, making it a preferred choice for roofing material manufacturers and suppliers.{Company Name} is at the forefront of this technological innovation in the roofing industry. With years of experience in manufacturing and engineering, the company has developed the Color Steel Roofing Roll Forming Machine to meet the evolving needs of the construction and building sector. Their commitment to excellence and customer satisfaction has led to the development of this cutting-edge machine, which has already garnered attention and praise from industry professionals.As a leading provider of roll forming equipment, {Company Name} takes pride in offering state-of-the-art solutions that empower manufacturers to achieve exceptional results. The Color Steel Roofing Roll Forming Machine is a testament to their dedication to advancing the roofing industry and providing reliable, cost-effective solutions that enhance production efficiency and quality.The introduction of the Color Steel Roofing Roll Forming Machine has sparked a new era in the roofing industry. Its impact is felt not only in the manufacturing process but also in the overall quality and performance of roofing materials. As the demand for durable, aesthetically pleasing, and cost-effective roofing solutions continues to grow, the Color Steel Roofing Roll Forming Machine stands as a beacon of innovation that addresses these needs head-on.In conclusion, the Color Steel Roofing Roll Forming Machine has redefined the standards for roofing material production. Its efficiency, versatility, and cost-effectiveness have made it an indispensable tool for manufacturers and suppliers across the industry. With {Company Name} leading the way, it is clear that the future of the roofing industry is brighter than ever, thanks to groundbreaking technological advancements like the Color Steel Roofing Roll Forming Machine.

750 Wave Corrugated Color Steel Roll Forming Machine: Raw Material PPGI/GI Steel Sheet for Sale

Are you in the construction industry and looking to invest in a reliable and high-quality color steel roll forming machine? Look no further! We bring you the 750 Wave Corrugated Color Steel Roll Forming Machine, which is now available for sale.This roll forming machine is designed to efficiently produce high-quality color steel sheets, making it an ideal choice for various construction projects. With its advanced technology and top-notch manufacturing, you can expect exceptional results every time.One of the standout features of this roll forming machine is its use of raw materials such as PPGI and GI steel sheets. PPGI (Pre-Painted Galvanized Iron) and GI (Galvanized Iron) are renowned for their durability, strength, and corrosion resistance. By utilizing these raw materials, the 750 Wave Corrugated Color Steel Roll Forming Machine ensures that the final product meets the highest industry standards.The manufacturing process of this roll forming machine is effortless and efficient. It begins with the feeding of the raw materials into the machine, which then goes through a series of stations. The machine meticulously shapes the steel sheets into the desired wave corrugation profile, resulting in perfect color steel sheets that are ready to be used in construction projects.The 750 Wave Corrugated Color Steel Roll Forming Machine boasts a robust construction that ensures its durability and longevity. Made with precision engineering and high-quality materials, this machine can endure heavy-duty usage without compromising on performance.Furthermore, the machine's easy-to-use control system allows for seamless operation. Even those with minimal experience can effortlessly operate and manage the entire production process. This user-friendly feature eliminates the need for extensive training, thereby increasing productivity and reducing downtime.The incorporation of advanced technology in this roll forming machine guarantees precision and accuracy. It is programmed to maintain consistent speeds and dimensions throughout the manufacturing process, resulting in perfectly shaped color steel sheets. With such precision, you can be confident that the final product will meet your exact specifications.In addition to its exceptional performance, the 750 Wave Corrugated Color Steel Roll Forming Machine offers a wide range of customization options. You can adjust the machine settings to produce color steel sheets of various sizes, thicknesses, and colors, catering to the unique requirements of your construction projects.Investing in the 750 Wave Corrugated Color Steel Roll Forming Machine is a wise decision for any construction business. Its reliability, efficiency, and versatility make it a valuable asset that will enhance your productivity and profitability.In conclusion, if you are in search of a top-of-the-line color steel roll forming machine, look no further than the 750 Wave Corrugated Color Steel Roll Forming Machine. With its utilization of raw materials such as PPGI and GI steel sheets, advanced technology, easy operation, and customization options, this machine sets itself apart from the competition. Don't miss out on the opportunity to boost your construction projects with this high-quality roll forming machine. Invest in the 750 Wave Corrugated Color Steel Roll Forming Machine today and experience its exceptional performance firsthand.Keywords: GP GI, color steel roll forming machine, 750 Wave Corrugated Color Steel Roll Forming Machine, PPGI, GI steel sheet, construction projects, top-notch manufacturing, durability, strength, corrosion resistance, efficiency, seamless operation, precision, customization options, productivity, profitability.

Practical Solar Support Forming Machine for Easy Control with Electrical Cabinet

Solar energy has been gaining popularity in recent times as it is a renewable and sustainable energy source that is eco-friendly. This has led to the increasing use of solar panels, which has resulted in the need for solar panel mounting bracket roll forming machines. A Solar Panel Mounting Bracket Roll Forming Machine is a very practical device that is used for manufacturing solar panel mounting brackets.The roll forming machine uses special equipment that is composed of a feed sheet, a roll forming machine, a cutting device, an electrical control cabinet, and hydraulic station. The machine produces high-quality solar panel mounting brackets that are strong and durable. Solar panel mounting brackets are very important because they hold the solar panels in place and keep them secure.LOTOS 2O19 Solar Support Forming Machine is one of the best solar panel mounting bracket roll forming machines in the market. The machine is very easy to control thanks to the electrical controlling cabinet. This means that the user can easily change the production process to suit their specific needs.The LOTOS 2O19 Solar Support Forming Machine is also very efficient, which makes it ideal for mass production. The machine produces solar panel mounting brackets in large quantities within a short period of time, which ensures that there is enough supply to meet the high demand.The machine has a unique design that ensures that it produces high-quality solar panel mounting brackets. The design includes a precision roller and a computer-controlled system that ensures that the brackets are uniform in size and shape. This ensures that the solar panels are securely held in place and do not fall or get damaged.The roll forming machine is composed of high-quality materials that are durable and long-lasting. This means that the machine can be used for many years without experiencing any wear and tear. It is also very easy to maintain, which reduces the overall maintenance cost.The LOTOS 2O19 Solar Support Forming Machine is very versatile, which means that it can be used to produce different types of solar panel mounting brackets. This is because the machine comes with different molds that can be used to produce different sizes and shapes of brackets. This flexibility makes it ideal for use in different types of solar panel projects.In addition to the LOTOS 2O19 Solar Support Forming Machine, the company also produces the Color Steel Solar Mounting Structure Roll Forming Machine. This machine is also used for manufacturing solar panel mounting brackets, but it is different from the LOTOS 2O19 Solar Support Forming Machine.The Color Steel Solar Mounting Structure Roll Forming Machine is designed to produce solar panel mounting brackets made from colored steel. This means that the brackets are not only strong and durable, but they are also aesthetically pleasing. The machine is also very efficient and easy to control, which makes it ideal for mass production.Overall, the use of solar panel mounting bracket roll forming machines has revolutionized the solar panel industry. The LOTOS 2O19 Solar Support Forming Machine and the Color Steel Solar Mounting Structure Roll Forming Machine are two of the best machines in the market. They are efficient, easy to control, and produce high-quality solar panel mounting brackets. As the demand for solar energy continues to grow, the use of such machines will become even more important.

Color Steel Sheet Roll Forming Machine: Everything You Need to Know

Color Steel Sheet Roll Forming Machine Industry Challenges Amid Growing DemandThe color steel sheet roll forming machine industry is one of the most rapidly evolving fields in the construction and manufacturing sector. This industry is defined by innovations in technology, design, and processes that address market demands and preferences. At the same time, it is also beset by constant challenges that require careful management and creative solutions.Amid the growing demand for color steel sheet roll forming machines, many companies are faced with a variety of challenges and issues. These challenges pertain to the production process, logistics, and distribution, as well as customer satisfaction and retention. One major challenge is the increasing competition in the industry, as more players enter the market and vie for market share.Moreover, while technological advancements in machinery have facilitated the automation of many manufacturing processes, new challenges have emerged. Manufacturers must adapt quickly to changing customer demands and trends while ensuring efficiency and product quality.One company that has overcome these challenges and continues to thrive in the industry is (remove brand name). (Company name) prides itself on its innovative approaches and dedication to customer satisfaction. As a leading manufacturer of roll forming machines, the company has expanded its product portfolio to meet the needs of a broad customer base.(Opinion quote from a company representative can be inserted here)Aside from offering high-quality processing equipment, (company name) also provides excellent after-sales support and service. This enables the company not only to attract new customers but also to retain loyal ones. (Company name) has a vast network of distributors and agents who help ensure that customers receive timely and dependable support.“Our competitive advantage is our ability to adapt quickly to changing market needs and trends,” says (company name) representative. “We stay on top of emerging technologies and design trends to ensure that our products are always up-to-date and meet the needs of our customers.”The company’s success can also be attributed to its investment in research and development. This investment enables (company name) to identify and address customer needs in a timely manner, providing customers with advanced and top-of-the-line products that meet their specific needs.Despite these advantages, (company name) is not immune to the challenges of the industry. One significant challenge is the supply chain disruption caused by Covid-19 pandemic, which has affected the company’s production capacity and delivery schedules. However, the company is continuously addressing this challenge by optimizing its logistics and production processes without compromising the quality of its products.In conclusion, the color steel sheet roll forming machine industry is a dynamic and evolving field that requires constant innovation and creativity. However, by staying on top of market trends and customer demands, maintaining a focus on quality, and investing in research and development, companies like (company name) have overcome many challenges and continue to thrive in the industry.