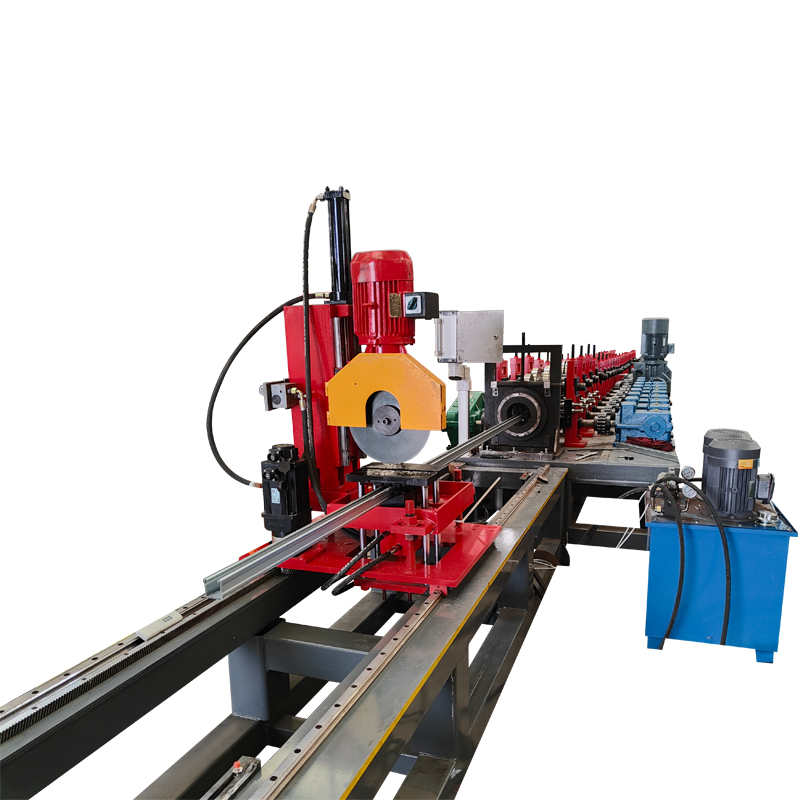

High-Quality Steel Roll Forming Machines for Efficient Production

By:Admin

{Company Name}, a leading manufacturer of steel roll forming machines, has been at the forefront of this technology, consistently delivering innovative and reliable machines to their clients. With a strong focus on quality and customer satisfaction, {Company Name} has established itself as a trusted name in the industry.

The steel roll forming machines produced by {Company Name} are known for their precision and versatility, allowing for the production of a wide range of steel products. From simple shapes to complex profiles, these machines can handle various thicknesses and widths of steel, making them suitable for a diverse range of applications. Whether it's for roofing, siding, automotive parts, or any other steel product, {Company Name}'s machines are designed to meet the specific requirements of their clients.

One of the key features of {Company Name}'s steel roll forming machines is their high level of automation. These machines are equipped with advanced control systems that ensure consistent and accurate forming, minimizing material waste and maximizing production efficiency. This level of automation not only increases the overall productivity of the manufacturing process but also reduces the need for manual labor, thus improving workplace safety and reducing labor costs.

In addition to their cutting-edge technology, {Company Name} also prides itself on the durability and reliability of their machines. By using high-quality materials and components, their machines are built to withstand the rigors of heavy-duty industrial use, ensuring long-term performance and minimal downtime for their clients.

Furthermore, {Company Name} offers comprehensive customer support and after-sales service, providing training, maintenance, and technical assistance to ensure that their clients get the most out of their machines. This dedication to customer satisfaction has earned {Company Name} a loyal and satisfied customer base, further solidifying their reputation as a top-tier manufacturer of steel roll forming machines.

Recently, {Company Name} has introduced their latest model of steel roll forming machine, featuring several advancements aimed at further improving productivity and performance. The new machine incorporates the latest technological innovations, such as enhanced control systems, increased forming speed, and improved material handling capabilities. These upgrades are designed to meet the evolving needs of the manufacturing industry and provide their clients with a competitive edge in the market.

{Company Name} has also made sustainability a priority in their new machine design, incorporating energy-efficient features and environmentally friendly materials. By reducing energy consumption and minimizing waste, this new machine aligns with the growing demand for eco-friendly manufacturing practices, further enhancing {Company Name}'s appeal to environmentally conscious clients.

With the release of their new and improved steel roll forming machine, {Company Name} is poised to continue leading the industry and setting new standards for quality and performance. Their commitment to innovation and customer satisfaction ensures that they will remain a trusted partner for manufacturers looking to invest in top-of-the-line steel forming technology.

In conclusion, {Company Name} has solidified its position as a leading manufacturer of steel roll forming machines, delivering advanced and reliable solutions to the manufacturing industry. With their latest offering, they are set to further enhance their reputation and continue providing their clients with the tools they need to succeed in today's competitive market.

Company News & Blog

Advanced Forming Equipment for Color Steel Profile Manufacturing

Color Steel Profile Forming Equipment Revolutionizes the Construction IndustryThe construction industry has witnessed yet another groundbreaking innovation with the introduction of Color Steel Profile Forming Equipment. This remarkable technology, developed by a leading company in the field, is set to revolutionize the way steel profiles are manufactured and utilized in various construction projects.With its advanced manufacturing capabilities, the Color Steel Profile Forming Equipment ensures precision and efficiency in the production of steel profiles. This cutting-edge machinery eliminates the need for manual labor, streamlining the manufacturing process and significantly reducing production time. By automating the production, companies can enhance productivity, maximize output, and minimize errors.The equipment incorporates state-of-the-art technology that enables it to produce steel profiles in various shapes and sizes. From simple profiles to intricate designs, the Color Steel Profile Forming Equipment is versatile enough to cater to a wide range of construction needs. This flexibility allows construction companies to meet the diverse requirements of different projects, giving them a competitive edge in the market.In addition to its versatility, the Color Steel Profile Forming Equipment is known for its exceptional quality and durability. The advanced machinery guarantees the production of high-quality steel profiles that exhibit superior strength and resilience. These profiles are capable of withstanding extreme weather conditions, making them ideal for both indoor and outdoor construction applications.Furthermore, the equipment has been designed with user-friendliness in mind. Its intuitive interface and easy-to-use controls make it accessible to operators of all skill levels. The company behind the technology has also ensured that comprehensive training and support systems are in place to assist customers in utilizing the equipment to its full potential.The introduction of the Color Steel Profile Forming Equipment is expected to have a profound impact on the construction industry. Its ability to produce steel profiles efficiently and accurately will not only benefit construction companies but also the clients they serve. The reduction in manufacturing time and potential cost savings will enable construction projects to be completed more rapidly and within budget.Moreover, the Color Steel Profile Forming Equipment has environmental benefits, as it promotes sustainable construction practices. By automating the manufacturing process, the equipment minimizes waste generation and optimizes the use of resources. This aligns with the global push toward sustainable development and green construction initiatives.The company responsible for this innovative technology has a long-standing reputation for delivering cutting-edge solutions to the construction industry. It has a proven track record of providing reliable and efficient machinery that has been widely adopted by construction companies across the globe.In conclusion, the Color Steel Profile Forming Equipment is set to revolutionize the construction industry with its precise manufacturing capabilities, versatility in producing various profiles, and its exceptional quality and durability. By reducing production time, enhancing productivity, and promoting sustainable construction practices, this innovative technology will inevitably reshape the way steel profiles are used in construction projects. With the support and expertise provided by the company behind the equipment, construction companies can expect to achieve higher levels of efficiency and competitiveness in the market.

Efficient and Reliable Color Steel Profile Manufacturing Machine Unveiled in Latest News

Color Steel Profile Manufacturing Machine Revolutionizes the IndustryIn an era of technological advancements, the manufacturing industry is witnessing a significant transformation. One such revolutionary innovation is the Color Steel Profile Manufacturing Machine, which has emerged as a game-changer for the steel profile manufacturing sector. With its advanced features and cutting-edge technology, this machine has the potential to revolutionize the way steel profiles are produced.Designed and developed by the renowned company [], the Color Steel Profile Manufacturing Machine combines precision engineering with state-of-the-art automation. This machine is equipped with the latest computer numerical control (CNC) technology, allowing for precise and efficient production of color steel profiles. By automating various processes, it eliminates the need for manual labor, reducing the potential for errors and improving productivity.One of the key features of this machine is its ability to produce color steel profiles of various shapes and sizes. Whether it is C-sections, Z-sections, or custom profiles, this machine can seamlessly manufacture them. This flexibility enables manufacturers to cater to a wide range of customer requirements, providing them with tailor-made solutions.The Color Steel Profile Manufacturing Machine is also equipped with a user-friendly interface, making it easy to operate and allowing for quick adjustments and setup changes. This feature enhances productivity as it reduces the time taken for machine setup and provides operators with a hassle-free working experience.Furthermore, this machine incorporates advanced safety features to ensure a secure working environment. With its automated sensor systems, it can detect any deviations from normal operations and promptly alert operators. This proactive approach to safety minimizes the risk of accidents and ensures the well-being of the workforce.One of the major advantages of this machine is its cost-effectiveness. By automating the manufacturing process, it significantly reduces labor costs and improves efficiency. Additionally, the precision and accuracy of the machine's output result in minimal material wastage, thereby reducing overall production costs. This cost-effectiveness makes it an attractive investment for steel profile manufacturers seeking to optimize their production processes.The Color Steel Profile Manufacturing Machine is not limited to the steel profile industry alone. Its applications extend to various sectors such as construction, infrastructure, and automotive. With the growing demand for steel profiles in these industries, this machine opens up new avenues for manufacturers to meet the market's needs efficiently.The environmental impact of this machine cannot be overlooked either. With the emphasis on sustainable practices, the Color Steel Profile Manufacturing Machine is designed to minimize energy consumption and reduce carbon emissions. Using advanced technology, it ensures that the manufacturing process is eco-friendly, aligning with the global efforts towards a greener future.In summary, the Color Steel Profile Manufacturing Machine revolutionizes the industry with its advanced features, automation, and cost-effectiveness. It caters to the diverse requirements of steel profile manufacturers and expands their capabilities to meet customer demands. With its user-friendly interface, safety features, and environmental benefits, this machine represents a significant leap forward in the manufacturing sector. As the industry continues to evolve, innovations like the Color Steel Profile Manufacturing Machine will play a crucial role in shaping its future.

Metal Glazed Tile Roll Forming Machine for Color Steel - Latest News Update

Color Steel Metal Glazed Tile Roll Forming Machine Revolutionizes Roofing IndustryThe global construction industry has long relied on traditional materials and techniques to build robust and aesthetically pleasing structures. However, as technology continues to advance, innovative solutions are emerging to streamline and enhance various construction processes. In this vein, the introduction of the Color Steel Metal Glazed Tile Roll Forming Machine is revolutionizing the roofing industry.Roofing materials play a crucial role in providing protection against external elements. Traditionally, materials like clay, concrete, and slate tiles have been used to create sturdy and visually appealing roofs. However, these materials have certain limitations, such as their weight, cost, and durability. Moreover, their installation process can be time-consuming and labor-intensive.The Color Steel Metal Glazed Tile Roll Forming Machine, developed by a leading machinery manufacturer, is designed to address these limitations and provide an efficient alternative for constructing high-quality roofs. This state-of-the-art machine enables the continuous production of metal glazed tiles with unparalleled precision, strength, and longevity.One of the key advantages of the Color Steel Metal Glazed Tile Roll Forming Machine is its ability to produce lightweight yet durable roofing materials. By using high-quality metal alloys, this machine creates tiles that are resistant to corrosion, weathering, and fire. Additionally, the lightweight nature of these tiles eases the burden on the building structure, reducing costs and strengthening overall stability.Furthermore, the Color Steel Metal Glazed Tile Roll Forming Machine has revolutionized the roof installation process. Traditional roofing materials often require time-consuming manual labor, resulting in increased project durations and expenses. However, this innovative machine automates the entire production process, significantly reducing labor costs and installation time. With integrated cutting, bending, and shaping mechanisms, the machine ensures each tile is uniformly manufactured to exact specifications, thereby streamlining the roofing process and delivering consistent quality.Additionally, the Color Steel Metal Glazed Tile Roll Forming Machine offers unrivaled design flexibility. Unlike traditional roofing materials, which are limited in terms of color, pattern, and shape, the machine can create a wide range of customizable tile designs. The machine supports various color coatings and embossing patterns, allowing architects and homeowners to personalize their roofs while enhancing the overall aesthetic appeal of the structure.With sustainability becoming increasingly important in the construction industry, the Color Steel Metal Glazed Tile Roll Forming Machine truly shines. The metal tiles produced by this machine are highly recyclable, reducing waste and contributing to a greener environment. Additionally, the sustainable production process of the machine minimizes its carbon footprint, making it an environmentally responsible choice for roofing needs.In conclusion, the Color Steel Metal Glazed Tile Roll Forming Machine is making waves in the roofing industry. Its lightweight yet durable metal tiles, efficient production process, design flexibility, and sustainability make it a game-changer in the construction sector. As technology continues to advance, it is clear that innovative solutions like this machine will reshape the way we build, proving that there is always room for improvement in even the most traditional industries.

Discover the Latest Roll Forming Machine at a Prominent Factory

Color Steel Roll Forming Machine Factory Expands Operations to Meet Growing DemandIn response to the increasing demand for high-quality, cost-effective roll forming machines, a leading manufacturer in the industry has recently announced a significant expansion of its operations. The Color Steel Roll Forming Machine Factory, leveraging its expertise and cutting-edge technology, aims to cater to the diverse needs of customers worldwide.With a reputation for excellence and a strong focus on customer satisfaction, Color Steel Roll Forming Machine Factory has established itself as a reliable and trusted provider of roll forming machines. Their wide range of products includes roof panel roll forming machines, wall panel roll forming machines, and various other types of machinery designed to meet specific industry requirements.The factory's roll forming machines are renowned for their durability, precision, and efficiency. Equipped with state-of-the-art technology, these machines are capable of seamlessly transforming raw materials into high-quality finished products, such as steel roof panels, wall panels, and other components essential to the construction industry. The strength and reliability of these machines ensure consistent production output and customer satisfaction.Color Steel Roll Forming Machine Factory takes pride in its adherence to strict quality control measures. Each machine undergoes rigorous testing and inspection before being delivered to customers. This meticulous attention to detail guarantees that every roll forming machine meets the factory's highest standards, ensuring superior performance and longevity.Recognizing the increasing demand for energy-efficient building solutions, Color Steel Roll Forming Machine Factory has also developed a range of environmentally friendly roll forming machines. These machines are designed to reduce energy consumption and minimize waste during the manufacturing process, aligning the factory's operations with environmentally sustainable practices.The factory's expansion plans come as a response to the growing demand for roll forming machines in various industries, including construction, automotive, and manufacturing. By increasing their production capacity, Color Steel Roll Forming Machine Factory aims to deliver products promptly and efficiently, even during times of high demand.To achieve this expansion, the factory intends to invest in advanced machinery and equipment, enabling them to streamline their manufacturing processes and enhance overall productivity. This investment will not only ensure the factory's ability to meet customer demands but also reinforce their commitment to delivering high-quality products consistently.In addition to expanding their operations, Color Steel Roll Forming Machine Factory is also dedicated to providing exceptional customer service. Their team of highly skilled professionals is committed to assisting customers at every stage of the purchasing process, from initial inquiries to after-sales support. By fostering long-term relationships with their clients, the factory aims to become a trusted partner and go-to source for all roll forming machine requirements.As Color Steel Roll Forming Machine Factory expands its operations, it looks forward to serving an even broader customer base. The factory's commitment to producing top-quality roll forming machines, coupled with its dedication to customer satisfaction, positions it as one of the leading manufacturers in the industry. With increased production capacity and an array of innovative products, the factory is well-prepared to meet the evolving needs of customers worldwide.

Futuristic Color Steel Roll Forming Machine: the Way Forward

Fully Automatic Color Steel Roll Forming Machine Revolutionizes Production ProcessIn today’s fast-paced industrial landscape, efficiency is key. In order to meet demanding marketplace requirements, manufacturers need to employ sophisticated equipment that can handle high volumes of production, while maintaining consistently high quality output. That’s why a new Fully Automatic Color Steel Roll Forming Machine has made waves in the industry, as it streamlines production processes and generates significant time and cost savings.Manufactured by [remove brand name] Company, a global leader in industrial equipment production, the Fully Automatic Color Steel Roll Forming Machine sets a new standard in industrial machinery. The machine boasts advanced technological features, such as a touch screen user interface, fully automatic operation, and a high-precision servo motor system. Additionally, the machine has been engineered to create high-quality finished products with minimal wastage - an important factor in today’s increasingly environmentally-conscious marketplace.According to [remove brand name] Company representatives, the Fully Automatic Color Steel Forming Machine is designed with user-friendliness and accessibility in mind. Unlike traditional roll forming machines, which are labor-intensive and require a significant amount of operator expertise, this new equipment is highly automated and can be operated by personnel with basic training. “Our aim is to simplify the roll forming process and make it more accessible for manufacturers of all sizes,” explains [remove brand name] spokesperson Alex Wang. “By automating certain tasks, the machine eliminates the need for manual intervention, which greatly increases efficiency and reduces the risk of errors.”In addition to being user-friendly, the Fully Automatic Color Steel Roll Forming Machine is customizable. The machine can create a variety of products, including roofing sheets, wall panels, and floor decking - all with different configurations and thicknesses. Because of its flexibility and versatility, the machine has been a game-changer for manufacturers in the construction industry, as it can easily adapt to the specific needs of different projects.Another important feature of the Fully Automatic Color Steel Roll Forming Machine is its high level of precision. According to [remove brand name] engineers, the machine’s servo motor system is capable of accurately controlling the movement of the rollers, which ensures that the resulting products are of uniform quality. This is particularly important for manufacturers who need to meet strict industry standards for their products.One of the primary benefits of the Fully Automatic Color Steel Roll Forming Machine is its ability to save time and money for manufacturers. By automating certain tasks and minimizing the risk of errors, the machine significantly increases production rates and reduces wastage. And because it requires less labor input, manufacturers can reduce their workforce and save money on labor costs. “We’re seeing manufacturers save up to 50% in labor costs thanks to the Fully Automatic Color Steel Roll Forming Machine,” states Alex Wang. “And that’s just the beginning - as they continue to use the machine, they’ll see additional savings in terms of product quality and efficiency.”Overall, the Fully Automatic Color Steel Roll Forming Machine marks a significant step forward in industrial machinery technology. By combining user-friendliness, customization, precision, and efficiency, the machine has become a favorite for manufacturers across the globe. And as the manufacturing industry continues to evolve, it’s clear that equipment like this will play an important role in shaping the future of production.

Efficient and Reliable Color Steel Sheet Roll Forming Machine Revolutionizes the Industry

Title: Cutting-Edge Steel Sheet Roll Forming Machinery Revolutionizes the Construction IndustryIntroduction:In an era of rapid technological advancements, the construction industry has witnessed several innovations that have greatly transformed the way buildings are designed and erected. Among these breakthroughs is the recent introduction of the cutting-edge Color Steel Sheet Roll Forming Machine, a revolutionary piece of equipment that promises to enhance the efficiency, accuracy, and sustainability of the construction process. Developed by a leading manufacturing company, this state-of-the-art technology is poised to revolutionize the way steel sheets are formed, offering numerous benefits to the industry.In-Depth Analysis:The Color Steel Sheet Roll Forming Machine represents a significant leap forward in the production of steel sheets, bringing a myriad of advantages that were previously unheard of in traditional manufacturing processes. By utilizing advanced roll forming techniques, this innovative machinery delivers highly customizable and precision-engineered steel sheets, perfectly suited for a wide range of construction applications.The machine's superior design and engineering allow for increased accuracy and consistency in the formation of steel sheets. Computer-controlled operations ensure precise bending, cutting, and shaping of the metal, resulting in standardized, high-quality products. This level of precision helps eliminate costly material wastage due to improper dimensioning, reducing overall project costs for construction companies.Additionally, the Color Steel Sheet Roll Forming Machine enhances production efficiency by automating the sheet formation process. Equipped with a user-friendly interface, operators can easily input the desired specifications into the machine's control panel, allowing for seamless and error-free operations. The automation feature also reduces labor requirements, enabling businesses to reallocate resources more effectively and increase productivity.Furthermore, the machine's compatibility with a wide range of steel materials, including galvanized, pre-painted, and stainless steel, offers further versatility and flexibility in construction applications. This adaptability allows for the creation of steel sheets in various colors, textures, and finishes, meeting the specific aesthetic requirements of different architectural designs.Beyond its immediate impact on the construction industry, the Color Steel Sheet Roll Forming Machine holds great promise for sustainable development. The technology significantly reduces the carbon footprint associated with steel sheet manufacturing by minimizing energy consumption and waste generation. Manufacturers can optimize material usage through efficient cutting methods and recycle excess materials, minimizing environmental impact and promoting a greener future.Moreover, the use of steel sheets produced by this advanced machine contributes to the overall sustainability of building structures. Steel is a highly sustainable material known for its durability, recyclability, and low maintenance requirements. By integrating steel sheets produced through this innovative method, buildings can achieve greater longevity, structural integrity, and energy efficiency, reducing the need for frequent repairs and replacements and decreasing the depletion of natural resources.Conclusion:The advent of the Color Steel Sheet Roll Forming Machine signifies a new era in construction technology, offering unprecedented precision, efficiency, and sustainability. Its introduction sets the stage for significant advancements in the manufacturing of steel sheets, ultimately transforming the way buildings are constructed. With its potential to reduce costs, enhance productivity, and minimize environmental impact, this cutting-edge machinery paves the way for a more sustainable and efficient construction industry.

Purchase Quality Color Steel Roll Forming Machine for Efficient Production of Roof Panels

for Sale and Roof Panel Roll Forming Machine.Color Steel Roll Forming Machine for Sale: A Guide to Choosing Your Best OptionIf you're running a business that deals with roofing or construction, you know that having the right equipment is crucial to delivering quality finished products to your clients. One equipment that is invaluable in the roofing and construction industry is the Color Steel Roll Forming Machine. This machine allows you to shape and form metal sheets into various roofing styles and designs that will satisfy the needs of your clients.However, choosing the right Color Steel Roll Forming Machine for your business can be challenging, given the numerous options available in the market today. In this blog, we will guide you on how to pick the best Color Steel Roll Forming Machine for sale, and what factors to consider when making your purchase.1. Quality of the MachineThe quality of the Color Steel Roll Forming Machine is critical to its efficiency and longevity. A machine made of high-quality materials will not only produce quality products but will also be durable enough to handle heavy-duty workloads. When you're shopping for a Color Steel Roll Forming Machine, look at the quality of its materials, including the frame, rollers, and other essential components.2. Ease of UseAnother factor to consider when looking for a Color Steel Roll Forming Machine for sale is the ease of use. You want a machine that is not only easy to operate but also easy to maintain and repair. A machine that requires specialized knowledge and skills to run will cost you both time and money. Thus, ensure that the machine you choose has clear instructions and that the supplier provides adequate support and maintenance services.3. Features and CapabilitiesDifferent Color Steel Roll Forming Machines come with varying features and capabilities. Some machines can only produce specific roofing styles and designs, while others offer a more extensive range of options. Consider the types of roofing projects you'll undertake and choose a machine that can produce the designs required for each project. Additionally, consider the speed at which the machine operates to ensure efficient production.4. PricePricing is an essential factor in choosing a Color Steel Roll Forming Machine for sale. While you want a machine that is of high quality and has all the features you need, you also want to ensure that it is affordable. Take time to compare prices from different suppliers, but ensure that the cheaper options do not compromise on the quality and functionality of the machine.Roof Panel Roll Forming MachineApart from the Color Steel Roll Forming Machine, another essential piece of equipment is the Roof Panel Roll Forming Machine. This machine is used to fabricate roof panels made of metals such as aluminum, copper, or steel. Here are a few tips on how to choose the best Roof Panel Roll Forming Machine.1. Material QualityEnsure that the Roof Panel Roll Forming Machine you choose is made of high-quality materials such as cast iron or steel. This will ensure that it can withstand heavy usage and last for long, even with limited maintenance. The material quality also determines the durability of the machine.2. Speed and AccommodationConsider the speed of the Roof Panel Roll Forming Machine and its ability to accommodate different panel sizes. Ensure that the machine can produce your desired panel sizes and designs within a reasonable time frame, especially if you have a high volume of orders.3. User FriendlyThe ease of use of the Roof Panel Roll Forming Machine is a crucial factor to consider. A straightforward machine that comes with instructions and support from suppliers will help you to deliver quality and efficient services.In conclusion, choosing the right Color Steel Roll Forming Machine and Roof Panel Roll Forming Machine can make all the difference in delivering quality roofing and construction products. By taking into account the key factors addressed in this blog, you can make an informed choice that meets the needs of your business and clientele.

High-Quality Steel Profile Manufacturing Machine for Your Business

Color Steel Profile Manufacturing Machine Revolutionizes the Building IndustryThe construction industry is always looking for innovative and efficient ways to produce building materials, and the latest advancement comes in the form of the Color Steel Profile Manufacturing Machine. This revolutionary machine is set to transform the way color steel profiles are produced, making the process faster, more precise, and more cost-effective than ever before.The Color Steel Profile Manufacturing Machine, developed by a leading manufacturer in the industry, is designed to meet the growing demand for high-quality color steel profiles. These profiles are essential components in modern construction, used in roofing, cladding, and structural applications. With the construction industry booming worldwide, there is a need for a reliable and efficient method of producing color steel profiles to meet this increasing demand.The newly developed machine integrates cutting-edge technology and advanced manufacturing processes to streamline the production of color steel profiles. It is capable of producing a wide range of profiles with different shapes, sizes, and colors, giving builders and architects the flexibility they need to bring their designs to life. The machine can also produce profiles with various coating options, providing durability and weather resistance for use in different environments.One of the key features of the Color Steel Profile Manufacturing Machine is its high level of automation. This not only increases the speed of production but also ensures consistent quality in every profile that is manufactured. The machine is equipped with precision tools and sensors that monitor the production process in real-time, allowing for adjustments to be made as needed to maintain quality and accuracy.Furthermore, the machine is designed with efficiency in mind, optimizing material usage and minimizing waste. This not only reduces production costs but also makes the manufacturing process more sustainable, aligning with the increasing focus on environmental responsibility in the construction industry.In addition to its advanced capabilities, the Color Steel Profile Manufacturing Machine is also designed for ease of use. It can be operated by a minimal number of skilled workers, reducing the need for extensive training and labor costs. The intuitive interface and user-friendly controls make it accessible to a wide range of operators, further enhancing its versatility and practicality.The introduction of this innovative machine is a significant milestone for the company and the industry as a whole. With its potential to revolutionize the production of color steel profiles, it is sure to have a profound impact on the construction sector. Architects, contractors, and developers will benefit from the increased efficiency and quality that this machine offers, ultimately leading to higher standards in building construction.The company, which has a solid reputation for delivering cutting-edge solutions to the construction industry, has once again demonstrated its commitment to innovation and excellence. With a strong focus on research and development, it has been able to stay ahead of the curve and anticipate the evolving needs of the market. The Color Steel Profile Manufacturing Machine is a testament to the company's dedication to providing state-of-the-art solutions that enable its customers to thrive in a competitive industry.Looking ahead, the company is poised to continue its leadership in the manufacturing of construction materials, leveraging its expertise and resources to drive further advancements in the field. As the demand for sustainable, high-performance building materials continues to grow, the company is well-positioned to play a pivotal role in shaping the future of construction.In conclusion, the Color Steel Profile Manufacturing Machine represents a significant leap forward for the construction industry. Its advanced technology, efficiency, and quality standards are set to transform the way color steel profiles are produced, setting a new benchmark for the sector. This innovation underscores the company's commitment to driving progress and delivering value to its customers, and it is sure to make a lasting impact on the built environment.

Revolutionary Fully Automatic Color Steel Roll Forming Machine Unveiled in Latest News

Fully Automatic Roll Forming Machine Revolutionizes Color Steel ProductionWith the constant innovation and development in the manufacturing sector, a new breakthrough has been achieved with the introduction of the fully automatic roll forming machine for color steel. This state-of-the-art technology is set to revolutionize the production process and enhance the efficiency and quality of color steel production.Color steel, also known as pre-painted steel, has gained immense popularity in various industries due to its versatility, durability, and aesthetic appeal. It is widely used in the construction of roofs, walls, and other structural components. Traditionally, color steel production involved manual labor that required considerable time and effort. However, with the advent of fully automatic roll forming machines, the production process has become significantly faster, more precise, and cost-effective.The innovative features of this advanced machine eliminate the need for manual intervention, resulting in increased productivity and reduced error rates. The roll forming machine operates seamlessly, starting from the loading of steel coils to the final product, with minimal human involvement. The machine incorporates cutting-edge technology that ensures precise shaping, bending, and cutting of the steel sheets, resulting in perfectly formed color steel components.One of the key advantages of the fully automatic roll forming machine is its ability to handle a wide range of color steel materials, including galvanized steel, galvalume steel, and various coated steel sheets. This flexibility allows manufacturers to cater to the diverse needs of their customers and offer a wide range of color options. The machine can effortlessly produce color steel profiles of various shapes and sizes, meeting the requirements of different construction projects.Furthermore, the fully automatic roll forming machine is equipped with an intelligent control system that enables smooth and efficient operation. The control system allows operators to set precise parameters, monitor the production process in real-time, and make adjustments as needed. This ensures consistent quality and minimizes material wastage, further optimizing the production efficiency.In addition to its operational efficiency, the fully automatic roll forming machine also prioritizes worker safety. With its advanced safety features and protective measures, the machine significantly reduces the risk of accidents and injuries during the production process. This creates a safer working environment and improves overall worker morale and satisfaction.As a leader in the manufacture and supply of roll forming machines, [Company Name] has introduced this cutting-edge technology to the market. The company's commitment to research and development has enabled them to design and produce machinery that meets the evolving needs of the industry. With extensive experience and expertise, [Company Name] has become a trusted name in the roll forming machine industry.The introduction of the fully automatic roll forming machine by [Company Name] signifies a leap forward in color steel production. This technology revolutionizes the manufacturing process, bringing numerous benefits to manufacturers, construction companies, and end-users alike. The increased speed, precision, and quality of color steel production will contribute to the advancement of the construction industry and fuel economic growth.In conclusion, the fully automatic roll forming machine has emerged as a game-changer in the color steel production industry. Its advanced features, efficient operation, and focus on worker safety make it an invaluable asset for manufacturers. With [Company Name] at the forefront of this technology, the future of color steel production is brighter than ever.

High-quality Color Steel Roll Forming Machine for GP/GI Steel Sheets

Introducing the GP GI Color Steel Roll Forming MachineIn the ever-evolving world of manufacturing, the demand for efficient and reliable roll forming machines is on the rise. Companies are constantly seeking innovative solutions to improve their production processes and meet the needs of their customers. It is in response to this demand that {Company Name} has introduced the GP GI Color Steel Roll Forming Machine – a state-of-the-art piece of equipment that promises to revolutionize the roll forming industry.{Company Name} has been a leading provider of roll forming solutions for over a decade. Their commitment to innovation and quality has earned them a reputation as a trusted partner for businesses across various industries. With the introduction of the GP GI Color Steel Roll Forming Machine, they aim to further solidify their position as a leader in the industry.The GP GI Color Steel Roll Forming Machine is designed to meet the diverse needs of modern manufacturing facilities. It is capable of producing high-quality color steel roll-formed products with a smooth finish and precise dimensions. The machine is equipped with advanced control systems that ensure consistent and accurate production, resulting in minimal material waste and increased efficiency.This roll forming machine is ideal for the production of a wide range of products, including roofing and wall panels, decking, and other structural components. Its versatility makes it a valuable asset for businesses looking to expand their product offerings and meet the demands of their customers.Furthermore, the GP GI Color Steel Roll Forming Machine is built with durability and reliability in mind. It is constructed with high-quality materials and components that can withstand the rigors of heavy-duty production. This ensures that businesses can rely on the machine to deliver consistent performance over the long term, minimizing downtime and maintenance costs.In addition to its technical capabilities, the GP GI Color Steel Roll Forming Machine is designed with user-friendliness in mind. It features intuitive controls and interface, making it easy for operators to set up and operate the machine with minimal training. This reduces the learning curve for new users and allows businesses to maximize the productivity of their workforce.{Company Name} is proud to offer comprehensive support and service for the GP GI Color Steel Roll Forming Machine. Their team of experienced professionals is available to provide installation, training, and ongoing maintenance to ensure that businesses can get the most out of their investment. This commitment to customer satisfaction sets {Company Name} apart as a trusted partner for businesses looking to enhance their production capabilities.With the introduction of the GP GI Color Steel Roll Forming Machine, {Company Name} continues to demonstrate their dedication to providing innovative solutions for the roll forming industry. As manufacturing trends and customer demands continue to evolve, businesses can rely on {Company Name} to deliver cutting-edge equipment that meets their needs and drives their success.In conclusion, the GP GI Color Steel Roll Forming Machine represents a significant advancement in the roll forming industry. Its advanced capabilities, durability, and user-friendly design make it a valuable asset for businesses seeking to enhance their production processes. With the support of {Company Name}, businesses can confidently invest in this state-of-the-art machine and position themselves for success in the competitive manufacturing landscape.