Advanced Roll Forming Machine for Color Steel Wall Panels: A Breakthrough Technology

By:Admin

Introduction:

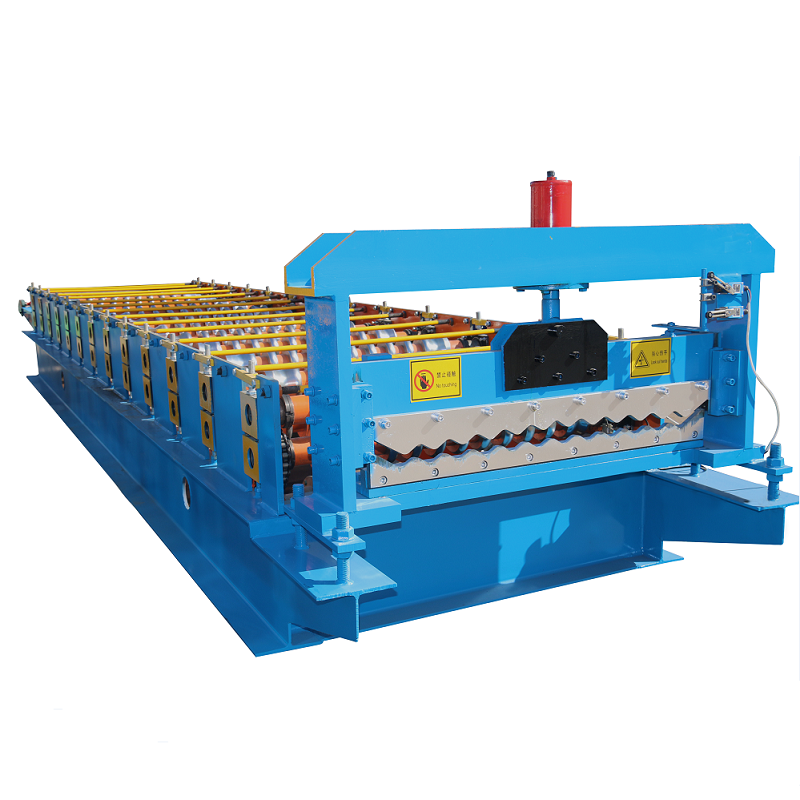

In a breakthrough development for the construction industry, a cutting-edge Color Steel Wall Panel Roll Forming Machine has been introduced by an industry-leading company. This technological marvel aims to streamline the process of manufacturing steel wall panels, revolutionizing the way buildings and structures are constructed. With its state-of-the-art features and precision engineering, this roll forming machine promises to enhance efficiency, reduce costs, and facilitate rapid deployment of high-quality steel panels in a variety of construction projects.

Advanced Features:

The Color Steel Wall Panel Roll Forming Machine incorporates a range of advanced features that make it stand out from traditional manufacturing methods. Equipped with the latest technology, this innovative machine offers unparalleled precision and flexibility in forming steel panels of various shapes and dimensions. Its computerized control system ensures accurate measurements and reduces human errors, resulting in consistently high-quality panels.

One of the key advantages of this advanced machine is its ability to efficiently produce steel panels in large quantities. Its robust design and high-speed operation maximize production capacity, thus catering to the ever-increasing demand for steel panels in the construction sector. This not only reduces manufacturing time but also facilitates faster completion of construction projects, leading to improved overall efficiency.

The machine's versatile nature allows it to produce steel panels with a wide range of colors and finishes. Its integrated color coating system offers an extensive palette of options, enabling architects and designers to unleash their creativity and customize panels according to their specific project requirements. This flexibility in design contributes to the aesthetic appeal of structures, enhancing their overall visual impact.

Moreover, this roll forming machine incorporates intelligent software that enables seamless integration with other manufacturing processes. It can be easily synchronized with robotic systems, stackers, and packaging units, further automating the production process. By minimizing manual intervention, this integration enhances worker safety, increases efficiency, and reduces production costs.

Environmental Impact and Sustainability:

In an era characterized by growing environmental consciousness, the Color Steel Wall Panel Roll Forming Machine sets new standards for sustainability. By utilizing precise measurements and minimizing material waste, it significantly reduces the amount of scrap generated during the manufacturing process. This not only minimizes environmental impact but also reduces costs associated with material loss, making it a financially viable option for companies.

Additionally, the steel panels produced by this roll forming machine boast high strength and durability, contributing to the longevity of constructed structures. Unlike traditional construction materials, these panels are resistant to corrosion, pests, and fire, ensuring the longevity and safety of buildings. This inherent resilience not only enhances the reputation of construction companies but also offers long-term benefits to building owners, making it an attractive investment for both parties.

Impact on the Construction Industry:

The introduction of the Color Steel Wall Panel Roll Forming Machine marks a significant turning point in the construction industry. Its ability to streamline manufacturing processes, increase production capacity, and reduce costs is expected to have a transformative effect on the sector. With faster turnaround times and improved quality, construction projects are likely to experience enhanced efficiency and higher customer satisfaction levels.

Furthermore, by offering flexibility in design and customization, this roll forming machine empowers architects, designers, and construction companies to create visually stunning structures that meet the unique needs and preferences of clients. It opens up new avenues for creativity and innovation, revolutionizing the way buildings are conceived and constructed.

Conclusion:

In summary, the introduction of the Color Steel Wall Panel Roll Forming Machine represents a significant leap forward in the construction industry. Its advanced features, precision engineering, and sustainability aspects position it as a game-changer. As this innovative machine becomes increasingly adopted in construction projects, it is poised to redefine the standards and possibilities of how structures are built, setting the industry on a path towards greater efficiency, sustainability, and architectural excellence.

Company News & Blog

Efficient Three-Layer Color Steel Roll Forming Machine: A Game-Changer in the Industry

Title: Advanced Three-layer Color Steel Roll Forming Machine Revolutionizes Metal Roofing ProductionIntroduction:In a pioneering development in the metal roofing industry, an innovative and cutting-edge Three-layer Color Steel Roll Forming Machine has been introduced by a prominent company. This revolutionary machinery, which combines superior technology and precision engineering, aims to transform the manufacturing process of color steel roofing sheets, further enhancing their quality and durability.The Three-layer Color Steel Roll Forming Machine is the brainchild of a highly respected industry leader, renowned for their commitment to excellence and continuous innovation. This advanced machinery promises to meet the increasing demand for high-quality color steel roofing sheets while ensuring speed, accuracy, and superior performance.1. Enhanced Design and Functionality:This state-of-the-art Three-layer Color Steel Roll Forming Machine showcases a meticulously crafted and robust design, utilizing the finest quality materials available. The sturdy frame and hardened rollers contribute to its durability, ensuring high-performance even in the most demanding production environments. The machine is equipped with advanced control systems, offering seamless operation and maximizing productivity.2. Unparalleled Efficiency and Speed:The Three-layer Color Steel Roll Forming Machine provides unparalleled efficiency, enabling the production of color steel roofing sheets at a significantly increased rate. With the integration of automated processes and precise cutting-edge technology, it accomplishes rapid roll forming and seamless welding, reducing production time without compromising on quality. This cutting-edge technology boosts productivity, enabling businesses to meet growing market demands.3. Precision and Versatility:This innovative machine boasts unmatched precision when it comes to roll forming techniques. Its adjustable rollers and multiple cutting blades enable precise sizing and cutting of the color steel sheets, ensuring uniformity and accuracy. Furthermore, its adaptability allows for customization, catering to a wide range of roof shapes and designs, meeting the diverse needs of builders and architects.4. Quality and Durability:The Three-layer Color Steel Roll Forming Machine emphasizes the creation of top-quality color steel roofing sheets. Manufactured with premium materials and unparalleled craftsmanship, the machine guarantees the production of durable and long-lasting roofing products. The precise control system ensures consistent quality by minimizing errors during the manufacturing process.5. Cost-effective and Energy-efficient:With its advanced automation and streamlined production process, the Three-layer Color Steel Roll Forming Machine significantly reduces labor costs and material waste, thereby increasing overall cost-effectiveness. Additionally, the energy-efficient design of the machinery reduces power consumption, ensuring a sustainable and environmentally-friendly production process.In summary, the introduction of the Three-layer Color Steel Roll Forming Machine represents a major technological leap in the metal roofing industry. Its advanced design, unparalleled efficiency, precision, and versatility pave the way for the production of high-quality color steel roofing sheets. Moreover, the machine's superior durability, cost-effectiveness, and energy efficiency increase its appeal to manufacturers worldwide. This groundbreaking innovation is set to revolutionize metal roofing production, enabling builders and architects to deliver exceptional roofing solutions to their customers.

Highly Efficient and Versatile Profile Roll Forming Machine for Color Steel

Title: Revolutionary Color Steel Profile Roll Forming Machine Revolutionizes the Construction IndustryIntroduction:The construction industry has witnessed a groundbreaking development with the introduction of an innovative Color Steel Profile Roll Forming Machine. This cutting-edge equipment has been designed to redefine the way steel profiles are produced for use in various building applications. The machine's advanced technology and high efficiency are set to revolutionize the construction sector worldwide. With the aim to enhance productivity, reduce costs, and improve quality, this Color Steel Profile Roll Forming Machine is set to become an indispensable tool for construction companies.Company Overview:The company behind this remarkable invention, referred to as "the manufacturer" in this article, has been a leader in the manufacturing sector for over three decades. With a strong focus on research and development, the manufacturer has successfully introduced a range of technologically advanced machines to meet the evolving needs of the global construction industry. The company prides itself on its commitment to innovation, efficiency, and sustainability.Features of the Color Steel Profile Roll Forming Machine:The Color Steel Profile Roll Forming Machine incorporates a range of cutting-edge features that make it stand out in the construction industry. Firstly, its fully automated operations significantly reduce the need for manual labor, resulting in increased productivity and improved safety. The machine's precision engineering ensures accurate profiling and efficient material usage, thereby minimizing waste.The roll forming process enables the creation of consistent steel profiles with complex shapes and sizes, making it ideal for various construction projects. This versatility allows the machine to produce a wide range of profiles, including roofing panels, wall cladding, and structural steel components. Additionally, the machine's modular design allows for easy customization and adaptability to meet specific customer requirements.Benefits for the Construction Industry:The introduction of this streamlined Color Steel Profile Roll Forming Machine offers numerous benefits to the construction industry. Firstly, the high-speed production capabilities enable the completion of projects in a shorter timeframe, leading to faster construction cycles and increased project turnover. This time efficiency translates into significant cost savings for construction companies.Furthermore, the machine's precision and consistency ensure that all profiles meet the required specifications, resulting in improved quality control. This leads to enhanced durability, reliability, and overall performance of the finished structures. Additionally, the machine's energy-saving features contribute to sustainability efforts within the industry, reducing carbon emissions and promoting environmental responsibility.Global Impact and Market Outlook:The Color Steel Profile Roll Forming Machine has garnered significant attention and interest from international markets. Its potential to revolutionize the construction industry has led to an increased demand for this advanced equipment across the globe. Construction companies are recognizing the need to adopt this technology, which promises to provide them with a competitive advantage and improve their bottom line.Conclusion:The Color Steel Profile Roll Forming Machine represents a significant milestone in the construction industry, propelling it towards a future of increased efficiency and productivity. With automated operations and precision engineering, this innovative machine exceeds traditional manufacturing methods, ensuring high-quality steel profiles for various construction applications. As this groundbreaking technology gains momentum worldwide, the construction industry embraces the opportunities it presents, reaffirming its commitment to progress and continual improvement.

Purchase Quality Color Steel Roll Forming Machine for Efficient Production of Roof Panels

for Sale and Roof Panel Roll Forming Machine.Color Steel Roll Forming Machine for Sale: A Guide to Choosing Your Best OptionIf you're running a business that deals with roofing or construction, you know that having the right equipment is crucial to delivering quality finished products to your clients. One equipment that is invaluable in the roofing and construction industry is the Color Steel Roll Forming Machine. This machine allows you to shape and form metal sheets into various roofing styles and designs that will satisfy the needs of your clients.However, choosing the right Color Steel Roll Forming Machine for your business can be challenging, given the numerous options available in the market today. In this blog, we will guide you on how to pick the best Color Steel Roll Forming Machine for sale, and what factors to consider when making your purchase.1. Quality of the MachineThe quality of the Color Steel Roll Forming Machine is critical to its efficiency and longevity. A machine made of high-quality materials will not only produce quality products but will also be durable enough to handle heavy-duty workloads. When you're shopping for a Color Steel Roll Forming Machine, look at the quality of its materials, including the frame, rollers, and other essential components.2. Ease of UseAnother factor to consider when looking for a Color Steel Roll Forming Machine for sale is the ease of use. You want a machine that is not only easy to operate but also easy to maintain and repair. A machine that requires specialized knowledge and skills to run will cost you both time and money. Thus, ensure that the machine you choose has clear instructions and that the supplier provides adequate support and maintenance services.3. Features and CapabilitiesDifferent Color Steel Roll Forming Machines come with varying features and capabilities. Some machines can only produce specific roofing styles and designs, while others offer a more extensive range of options. Consider the types of roofing projects you'll undertake and choose a machine that can produce the designs required for each project. Additionally, consider the speed at which the machine operates to ensure efficient production.4. PricePricing is an essential factor in choosing a Color Steel Roll Forming Machine for sale. While you want a machine that is of high quality and has all the features you need, you also want to ensure that it is affordable. Take time to compare prices from different suppliers, but ensure that the cheaper options do not compromise on the quality and functionality of the machine.Roof Panel Roll Forming MachineApart from the Color Steel Roll Forming Machine, another essential piece of equipment is the Roof Panel Roll Forming Machine. This machine is used to fabricate roof panels made of metals such as aluminum, copper, or steel. Here are a few tips on how to choose the best Roof Panel Roll Forming Machine.1. Material QualityEnsure that the Roof Panel Roll Forming Machine you choose is made of high-quality materials such as cast iron or steel. This will ensure that it can withstand heavy usage and last for long, even with limited maintenance. The material quality also determines the durability of the machine.2. Speed and AccommodationConsider the speed of the Roof Panel Roll Forming Machine and its ability to accommodate different panel sizes. Ensure that the machine can produce your desired panel sizes and designs within a reasonable time frame, especially if you have a high volume of orders.3. User FriendlyThe ease of use of the Roof Panel Roll Forming Machine is a crucial factor to consider. A straightforward machine that comes with instructions and support from suppliers will help you to deliver quality and efficient services.In conclusion, choosing the right Color Steel Roll Forming Machine and Roof Panel Roll Forming Machine can make all the difference in delivering quality roofing and construction products. By taking into account the key factors addressed in this blog, you can make an informed choice that meets the needs of your business and clientele.

Steel Roll Forming Machine Factory: The Latest News and Updates

Title: Leading Steel Roll Forming Machine Factory Breaks Ground in a Quest for ExcellenceSubtitle: Advancing the Steel Roll Forming Industry with Cutting-Edge Technology and Unparalleled Expertise[City, Date] - The steel roll forming industry is set for a remarkable transformation as a pioneering factory emerges in the heart of the manufacturing landscape. Merging innovative technology with unrivaled expertise, this new venture aims to revitalize the sector through its commitment to excellence. Combining state-of-the-art machinery with a skilled workforce, this Color Steel Roll Forming Machine Factory - the newest frontrunner in the market - is set to revolutionize the way steel components are produced and utilized in various industries.The factory prides itself as a business dedicated to precision and efficiency. By adhering to strict quality control measures, it intends to surpass customer expectations and redefine the standard in steel roll forming. Utilizing cutting-edge technology, the factory aims to maximize productivity while reducing production costs, making sustainable steel manufacturing a reality.At the heart of the Color Steel Roll Forming Machine Factory's success lies its unwavering dedication to research and development. Their team of engineers and designers work tirelessly to create innovative solutions that address evolving market demands. By staying ahead of the curve, the factory ensures its customers consistently receive the most advanced and reliable steel roll forming machinery available, facilitating their success in an increasingly competitive marketplace.The foundation of the factory's operations is built upon a carefully selected team of dedicated professionals. From skilled technicians to experienced production managers, the workforce brings a wealth of knowledge and proficiency to the table, ensuring flawless execution of every project. The high level of expertise within the factory guarantees the consistent delivery of high-quality, precision-engineered steel components demanded by various industries, such as automotive, construction, and infrastructure development.One of the factory's primary objectives is to streamline the production process without compromising on quality. Through meticulous planning and optimization, the factory aims to attain the highest operational efficiency while adhering to the strictest international standards and regulations. By integrating automation and digitization, the factory seeks to eliminate human errors and enhance the overall speed and accuracy of its roll forming machines. This level of precision is crucial in meeting the diverse needs of clients, especially those requiring complex or customized steel components.In line with its commitment to sustainability, the factory has implemented eco-friendly practices throughout its operations. By utilizing energy-efficient technologies and reducing waste, the factory aims to minimize its environmental impact. With sustainability at its core, the Color Steel Roll Forming Machine Factory aims to become a model for environmentally responsible manufacturing practices.The factory's strategic location within the city's manufacturing hub further amplifies its ability to serve a global clientele. Its close proximity to major transport networks allows for seamless distribution and prompt delivery of steel components worldwide. This strategic advantage, combined with the factory's commitment to quality and innovation, positions it as the go-to destination for steel roll forming solutions on a global scale.As the Color Steel Roll Forming Machine Factory gears up for production commencement, avid industry watchers eagerly anticipate the transformation it promises to bring to the steel roll forming landscape. With its unwavering commitment to excellence, cutting-edge technology, and a relentless pursuit of innovation, this factory is poised to redefine industry standards and elevate the steel roll forming sector to new heights.###Note: Information between curly braces {} refers to specific details about the company that need to be provided in order to complete the news article.

Double-layer Color Steel Roll Forming Machine: Compact, Cost-saving Solution for Efficient Production

Title: Innovations in Double-layer Color Steel Roll Forming Machine: Boosting Efficiency and Cost SavingsIntroduction:In the ever-evolving world of manufacturing, the demand for efficient and cost-effective machinery is increasing. The latest innovation, the ZT-840/980 Double-layer Color Steel Roll Forming Machine, is revolutionizing the industry with its groundbreaking design and multifunctional capabilities. This blog post will explore the features, benefits, and applications of this cutting-edge machine, while emphasizing its significant advantages over single-layer alternatives.1. The Double-layer Design Advantage:The ZT-840/980 Double-layer Color Steel Roll Forming Machine stands out from its competitors due to its ingenious double-layer design. By integrating two different plate types into a single machine, it enables enhanced flexibility and versatility in the manufacturing process. This innovation not only saves valuable floor space but also simplifies transportation, resulting in reduced costs and improved efficiency.2. Superior Cost Savings:Manufacturers are constantly aiming to optimize their production costs, and the ZT-840/980 Double-layer Color Steel Roll Forming Machine is a game-changer in this regard. By incorporating two types of plates within one machine, it eliminates the need for additional equipment, thus significantly reducing overhead expenses. Moreover, the machine's small footprint not only maximizes space utilization but also lowers energy consumption, further contributing to long-term cost savings.3. Tailored Solutions to Meet User Requirements:In today's highly competitive market, customized solutions are paramount to success. The ZT-840/980 Double-layer Color Steel Roll Forming Machine offers a comprehensive sales service that includes special designs and manufacturing processes tailored to meet individual user requirements. With this flexibility, manufacturers can optimize their production processes, leading to improved output, reduced scrap rates, and increased customer satisfaction.4. A Comprehensive User Guide:As the adoption of double-layer roll forming machines is relatively new, having comprehensive user guidance is crucial. The ZT-840/980 Double-layer Color Steel Roll Forming Machine comes with an extensive user guide that assists operators in understanding the equipment thoroughly. This guidance covers installation, commissioning, and regular maintenance procedures, enabling seamless operation and reducing downtime, ultimately enhancing productivity and profitability.Application and Benefits of Double-layer Roll Forming:Without compromising on quality or efficiency, the ZT-840/980 Double-layer Color Steel Roll Forming Machine caters to a wide range of applications across various industries. Some notable applications include:1. Roofing and Cladding Systems:The machine's ability to form and shape two different colored steel layers allows for quick, efficient production of roofing and cladding systems. Whether it's for residential, commercial, or industrial purposes, the double-layer roll forming technique ensures durability, weather resistance, and an attractive appearance.2. Garage and Industrial Door Manufacturing:Double-layer roll forming lends itself exceptionally well to the production of door frames for garages and industrial environments. The machine's versatility and high precision allow for the creation of interlocking panels, improving security, insulation, and ease of installation.3. Agricultural Applications:From poultry houses to barns, agricultural structures often require efficient and cost-effective roofing solutions. The ZT-840/980 Double-layer Color Steel Roll Forming Machine can reliably manufacture multi-layered steel sheets with insulating properties, ensuring a conducive environment for livestock and crop production.Conclusion:The ZT-840/980 Double-layer Color Steel Roll Forming Machine displays a range of advantages over traditional single-layer alternatives. Its innovative design, cost-saving functionalities, and ability to meet diverse user requirements have positioned it at the forefront of the manufacturing industry. By embracing this cutting-edge technology, manufacturers can improve productivity, enhance their product offerings, and achieve sustainable growth in today's competitive market.Keywords: - Double-layer roll forming machine- Color steel roll forming machine- ZT-840/980 roll forming machine- Double-layer design- Cost savings- Customized solutions- User guide- Roofing and cladding systems- Garage and industrial doors- Agricultural applications

Discover the Latest Innovations in Steel Roll Forming Machines

Color Steel Roll Forming Machine: Empowering the Steel Industry with Efficiency and PrecisionThe manufacturing industry, particularly the steel industry, has been a significant source of growth and prosperity for the economy at large. As the world continues to develop and progress, demands for high-quality steel products continue to rise accordingly. To meet these demands while remaining competitive, businesses, and manufacturers must strive to employ state-of-the-art machinery and equipment. In this vein, the Color Steel Roll Forming Machine, developed by the team at [company name], has revolutionized the industry.The Color Steel Roll Forming Machine has been designed for the efficient and precise production of high-quality steel products. This advanced piece of equipment uses a cold-roll forming process to transform flat sheets of metal into complex shapes and designs with ease. The finished products are durable, and aesthetically pleasing and can be used in various construction and building applications, including roofing, wall and ceiling cladding, and insulation.This innovative industrial machine boasts a range of features that set it apart from traditional roll-forming machines. The machine's advanced software and hardware systems ensure a high degree of accuracy and precision in the forming process. It is equipped with state-of-the-art controls that allow operators to program the machine to produce a wide range of shapes and designs, without requiring manual adjustments for each operation. Further, it has a continuous production process, which eliminates delays, reduces waste, and increases productivity.One significant benefit of using the Color Steel Roll Forming Machine is its versatility. The machine can work with a range of metals, including aluminum, copper, and stainless steel. It can form steel sheets into various profiles, including corrugated, trapezoidal, and tile shapes, making it a versatile and cost-effective solution for businesses that require custom-made steel products.[Company name] is a well-known player in the steel manufacturing industry, providing a broad range of products and services to customers all over the world. Their dedication to producing high-quality products is exemplified in their use of the Color Steel Roll Forming Machine, which has helped them maintain a competitive edge over their rivals.Their machines have been manufactured with the most advanced technology and materials, ensuring precise and reliable performance in demanding manufacturing environments. [Company name] understands that the investment made for such an innovative machine is significant, and in response, they provide ongoing support services to their clients. Their expertise in repair and maintenance guarantees that their customers' machines won't remain idle should any breakdowns occur.The Color Steel Roll Forming Machine has proved to be a game-changer in the steel manufacturing industry. It has reduced the time, resources, and labor required for producing custom products, thereby increasing profitability and efficiency for manufacturers. Moreover, it has enabled manufacturers to meet the ever-increasing demands of customers for high-quality steel products. Notably, the most significant benefit of using this machine is the consistently high-quality products it produces, which meet and exceed industry standards.In conclusion, the Color Steel Roll Forming Machine is an indispensable tool for modern steel manufacturers. Its unique combination of efficiency and precision has revolutionized the steel industry, resulting in higher quality products, increased productivity, and reduced costs. If your business is looking for an innovative solution to steel fabrication, you need to consider incorporating the Color Steel Roll Forming Machine into your operations. With [company name] as your partner, this machine provides an unbeatable solution for all your steel fabrication needs.

Application Characteristics of Color Steel Glazed Tile Roll Forming Machine: A Comprehensive Analysis

Color Steel Glazed Tile Roll Forming Machine: A Must-Have for the Construction IndustryThe construction industry has seen significant growth over the years. The demand for better-quality buildings has led to the development of new construction technologies. One such technology that has gained tremendous popularity is the use of color steel glazed tiles for roofing. The reason color steel glazed tiles have become a preferred choice for roofing is because of their durability, strength, and excellent appearance.To manufacture these tiles, the industry requires a reliable color steel glazed tile roll forming machine. These machines have become quite prevalent in the construction sector due to the high demand for color steel glazed tiles. If you are looking for a reliable color steel glazed tile roll forming machine, then look no further than Zhejiang Jinggong Science & Technology Co., Ltd.Application CharacteristicsThe color steel glazed tile roll forming machine is designed to produce high-quality glazed tiles used for roofing. The machine is easy to use and operate, consisting of several parts, including a feed introduction platform, a forming host, a die pressing device, a forming and shearing device, a hydraulic station, and a computer control system. The machine is capable of producing color steel glazed tiles of different shapes and sizes, based on the client requirements.One of the notable features of this machine is its accuracy and precision. It guarantees that every tile produced is of the same high standard and quality. The machine is also energy-efficient, which means it consumes less power compared to similar machines in the market. It has a low maintenance cost, which makes it a cost-effective investment for businesses in the construction industry.Color Steel Roofing Roll Forming MachineZhejiang Jinggong Science & Technology Co., Ltd. provides a wide range of color steel roofing roll forming machines for clients in the construction industry. These machines are designed to manufacture roofing sheets with varying shapes, sizes, and thicknesses. The machines are easy to use and operate, thanks to their user-friendly interface.The company's color steel roofing roll forming machines are designed using the latest technology to ensure high-quality, durable, and consistent products. The machines have a high production capacity, which means they can manufacture a large number of roofing sheets in a short period. They are also energy-efficient, with low maintenance costs, making them a valuable investment for businesses in the construction industry.ConclusionThe use of color steel glazed tiles for roofing in the construction industry has become increasingly popular due to their durability, strength, and excellent appearance. To manufacture these tiles, businesses require a reliable color steel glazed tile roll forming machine. Zhejiang Jinggong Science & Technology Co., Ltd. provides the perfect solution for this need by offering high-quality and energy-efficient machines.The company's color steel roofing roll forming machines are designed to produce roofing sheets of different shapes, sizes, and thicknesses. They are durable, high-quality, easy to operate, and are an excellent investment for businesses in the construction industry. So, if you are looking for a reliable, efficient, and high-quality color steel roofing roll forming machine, look no further than Zhejiang Jinggong Science & Technology Co., Ltd.

Automatic Double Layer Roll Forming Machine for Color Steel Roof and Wall Panels - Efficient Metal Sheet Pressing Machine at Competitive Price

Title: Enhancing Efficiency and Precision with the Color Steel Wall Panel Roll Forming MachineIntroduction:In today's competitive construction market, the demand for efficient and high-quality roofing and wall panels is constantly escalating. To meet these demands, the introduction of advanced technologies has significantly transformed the manufacturing processes in the metal sheet industry. One such technological marvel is the Color Steel Wall Panel Roll Forming Machine. This blog aims to explore the key features, benefits, and the significance of this machine in the industry.I. Understanding the Color Steel Wall Panel Roll Forming Machine:The Color Steel Wall Panel Roll Forming Machine is an automatic metal sheet pressing machine designed specifically to produce double-layered color steel roofing and wall panels. Manufactured by Zhangjiagang Gihua Machinery Co., this machine is equipped with state-of-the-art mechanisms to ensure high precision, efficiency, and durability.II. Key Features and Benefits:1. Automated Pressing Process: This machine incorporates advanced automation technology, allowing for seamless and precise operation. Manual labor is significantly reduced, minimizing human error and enhancing overall productivity.2. Double-Layered Formation: The Color Steel Wall Panel Roll Forming Machine has the capability to produce double-layered panels, providing immense versatility in design options. This flexibility caters to varying architectural and construction requirements.3. High-Speed Production: With the capacity to operate at a speed of 0-15 meters per minute, this machine accelerates the manufacturing process, ultimately resulting in increased output and reduced project turnaround time.4. Quality Assurance: The use of this machine ensures consistent panel formations with accurate dimensions. It creates flawlessly shaped and aligned panels, guaranteeing a top-quality end product that adheres to industry standards.5. Durability and Longevity: Constructed with robust materials, the Color Steel Wall Panel Roll Forming Machine exhibits exceptional durability, enabling it to withstand prolonged usage without compromising on performance. This extends its lifespan and provides long-term value for investment.6. Versatile Applications: The machine effortlessly handles colored glaze steel, making it suitable for various industries, such as construction, infrastructure development, and architectural design. It caters to diverse needs, be it residential, commercial, or industrial projects.III. Importance of Keywords for SEO:To enhance the online visibility and reach of this blog, specific keywords play a crucial role. By including appropriate keywords like "Color Steel Wall Panel Roll Forming Machine," "Metal Sheet Pressing Machine," and "Double Layer Roll Forming Machine," search engines can better understand the content and ensure higher ranking in relevant search results.Conclusion:The Color Steel Wall Panel Roll Forming Machine by Zhangjiagang Gihua Machinery Co. has revolutionized the metal sheet industry, providing improved efficiency, precision, and durability. With its automated processes and ability to produce double-layered steel panels, this machine offers enticing benefits to manufacturers, enabling them to meet the growing demands of the construction market. By embracing advanced technologies like these, the industry can elevate productivity, deliver superior quality, and stay ahead of the competition.

Steel Roll Forming Machine: A Revolution in Construction Industry

Title: Innovative Metal Forming Machine Revolutionizes Steel Roll ManufacturingIntroduction:Steel roll manufacturing has witnessed a significant breakthrough with the introduction of a cutting-edge metal forming machine. This revolutionary technology, developed by leading industry experts {}, promises to redefine the process of producing high-quality IBR color steel rolls. The advanced capabilities and efficiency of this machine are set to transform the steel roll manufacturing sector, enabling companies to meet the growing demands of various industries.Body:1. Traditional Challenges and Limitations:Metal forming for IBR color steel rolls has traditionally been a time-consuming and labor-intensive process. The conventional methods involve multiple stages of manual labor, leading to inconsistencies, lower production rates, and increased costs. These limitations have hindered the growth and scalability of the industry.2. Introduction of the Innovative Metal Forming Machine:Recognizing the need for a more efficient and streamlined manufacturing process, {} has developed a state-of-the-art metal forming machine. This technology integrates cutting-edge automation and precision engineering to facilitate the seamless production of IBR color steel rolls.3. Advanced Features and Capabilities:The newly developed machine boasts a range of advanced features that deliver exceptional performance and consistency. Its state-of-the-art control system enables precise adjustments of critical parameters, ensuring the production of consistently high-quality IBR color steel rolls. The machine also incorporates an intelligent material feeding system that optimizes material usage, minimizing waste and enhancing overall efficiency.4. Increased Production Efficiency:With the implementation of this innovative metal forming machine, the production efficiency of IBR color steel rolls is set to increase significantly. The automated processes eliminate manual errors and ensure consistent quality throughout the manufacturing process. The machine's high-speed operation enables faster production rates, meeting market demand swiftly and effectively.5. Enhanced Design Flexibility:The metal forming machine allows for greater design flexibility, enabling the production of IBR color steel rolls in various shapes, sizes, and colors. This flexibility has wide-ranging implications for diverse industries, such as construction, automotive, and manufacturing, as it enables the manufacture of customized steel rolls to meet specific project requirements.6. Cost-effectiveness and Sustainability:The advanced automation and optimization features of the metal forming machine contribute to cost reduction and sustainability. With reduced labor requirements and minimized material waste, manufacturers can achieve higher profitability while reducing their carbon footprint. This technological advancement aligns with the global industry's increasing focus on sustainable production practices.7. Market Impact and Future Prospects:The introduction of this groundbreaking metal forming machine is poised to revolutionize the IBR color steel roll manufacturing industry. Its ability to streamline production processes, improve quality, and increase design flexibility will positively impact market competitiveness and growth. Furthermore, it opens up new opportunities for steel roll manufacturers to explore a wider range of applications and cater to evolving customer requirements.Conclusion:The introduction of the advanced metal forming machine by {} promises to transform the steel roll manufacturing industry. Its cutting-edge features, enhanced efficiency, design flexibility, and sustainability aspects position it as a game-changer in the market. With this innovative technology at their disposal, manufacturers can drive growth, meet rising demands, and deliver superior quality IBR color steel rolls to various industries.