High-Quality Profile Roll Forming Machine for Color Steel – Everything You Need to Know

By:Admin

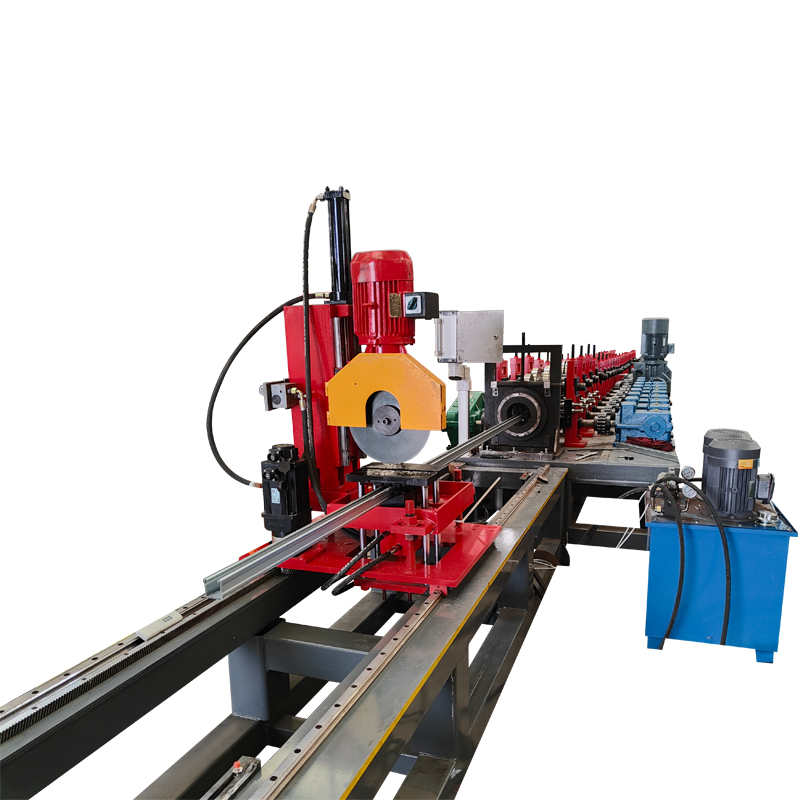

The Color Steel Profile Roll Forming Machine from (company name) is a leading player in the industry, offering state-of-the-art equipment that meets the diverse needs of its customers. With a commitment to innovation and excellence, the company has established itself as a trusted provider of roll forming solutions.

The Color Steel Profile Roll Forming Machine is designed to meet the demands of modern manufacturing, with features that enable seamless operation and optimal performance. Equipped with advanced controls and automation, the machine allows for precise and customizable production of steel profiles, ensuring high-quality output for various applications.

One of the key advantages of the Color Steel Profile Roll Forming Machine is its versatility. It can produce a wide range of steel profiles, including roofing panels, wall cladding, decking sheets, and other custom profiles to meet specific design requirements. This flexibility makes it an invaluable asset for companies in the construction, automotive, and manufacturing industries.

In addition to its versatility, the Color Steel Profile Roll Forming Machine is also known for its efficiency and productivity. The machine is designed for high-speed production, allowing for rapid turnaround times and increased output. This, in turn, helps companies meet tight deadlines and maintain a competitive edge in the market.

Furthermore, the Color Steel Profile Roll Forming Machine is engineered for durability and reliability. With robust construction and high-quality components, the machine is built to withstand the demands of heavy-duty production environments, ensuring long-term performance and minimal downtime for maintenance.

The Color Steel Profile Roll Forming Machine is also designed with user-friendly features that make it easy to operate and maintain. Intuitive controls and ergonomic design elements enhance the overall user experience, while also promoting safety and efficiency in the workplace.

As a leading provider of roll forming solutions, (company name) has a proven track record of delivering high-quality equipment and exceptional customer service. The company’s dedication to innovation and customer satisfaction has earned it a solid reputation in the industry, with a growing customer base that relies on its expertise and support.

In addition to its Color Steel Profile Roll Forming Machine, (company name) offers a comprehensive range of roll forming equipment and services, including design consultation, installation, training, and ongoing technical support. This full-service approach ensures that customers receive end-to-end solutions that meet their specific needs and contribute to their success.

With a commitment to excellence and a focus on meeting the evolving needs of the manufacturing industry, (company name) continues to lead the way in roll forming technology. The Color Steel Profile Roll Forming Machine is just one example of the company’s dedication to providing cutting-edge solutions that drive efficiency, productivity, and quality in steel profile production.

In conclusion, the Color Steel Profile Roll Forming Machine from (company name) is a game-changing solution for companies in the manufacturing industry. With its advanced technology, versatility, efficiency, and durability, the machine is poised to make a significant impact on the way steel profiles are produced, setting new standards for quality and performance. As (company name) continues to innovate and deliver top-notch roll forming solutions, it is clear that the future of manufacturing is in good hands.

Company News & Blog

High-Quality Color Steel Sheet Roll Forming Machine for Efficient Production

Color Steel Sheet Roll Forming Machine Revolutionizes Manufacturing ProcessIn the highly competitive world of metal sheet manufacturing, companies are always on the lookout for innovative technology that can help them streamline their production processes and stay ahead of the competition. One such technology that has been making waves in the industry is the Color Steel Sheet Roll Forming Machine.This revolutionary machine has been developed by a leading company in the field of metal sheet manufacturing. Drawing on their years of expertise and industry knowledge, the company has designed a machine that is set to revolutionize the way metal sheets are produced.The Color Steel Sheet Roll Forming Machine is an advanced piece of equipment that is designed to roll-form steel into a variety of shapes and sizes. It is versatile and can be used to create a wide range of products, from roofing and wall cladding to decking and flooring. The machine is capable of producing high-quality, precision-engineered metal sheets that are not only durable and weather-resistant but also visually appealing.One of the key features of the Color Steel Sheet Roll Forming Machine is its efficiency. The machine is highly automated, which means that it requires minimal human intervention to operate. This not only speeds up the manufacturing process but also reduces the risk of errors and inconsistencies in the final product. The machine is also equipped with advanced control systems that allow for precise adjustments to be made, ensuring that the finished products meet the strictest quality standards.In addition to its efficiency, the Color Steel Sheet Roll Forming Machine is also highly versatile. It is capable of processing a wide range of materials, including galvanized steel, stainless steel, and aluminum. This makes it a valuable asset for manufacturers who work with different types of metals and need a machine that can adapt to their changing needs.Furthermore, the Color Steel Sheet Roll Forming Machine is designed with the environment in mind. It is equipped with energy-saving features that help to reduce its carbon footprint, making it a sustainable choice for manufacturers who are committed to reducing their environmental impact.The company behind the Color Steel Sheet Roll Forming Machine has a long-standing reputation for excellence in the field of metal sheet manufacturing. With years of experience and a deep understanding of the industry, they have been able to develop a machine that is not only technologically advanced but also practical and reliable.The company's team of engineers and designers have worked tirelessly to ensure that the Color Steel Sheet Roll Forming Machine meets the highest standards of quality and performance. They have taken into account the needs and feedback of their customers, as well as the latest advancements in technology, to create a machine that is truly cutting-edge.As a result of their efforts, the Color Steel Sheet Roll Forming Machine has already garnered attention from manufacturers around the world. Many companies are eager to adopt this new technology in order to enhance their production capabilities and gain a competitive edge in the market.In conclusion, the Color Steel Sheet Roll Forming Machine represents a significant advancement in the field of metal sheet manufacturing. With its efficiency, versatility, and environmental sustainability, it is set to transform the way metal sheets are produced and pave the way for a new era of innovation in the industry. As more manufacturers embrace this technology, we can expect to see a shift towards more cost-effective, high-quality, and sustainable metal sheet products in the market.

Roll Forming Machine for Color Steel Production

Title: Advanced Color Steel Roll Forming Machine Revolutionizes the Steel Manufacturing IndustryIntroduction:With an ever-increasing demand for high-quality and sustainable construction materials, the global steel manufacturing industry has witnessed a significant technological advancement. The latest state-of-the-art Color Steel Roll Forming Machine has emerged as a game-changer, enabling efficient and precision-based production of color steel rolls.This groundbreaking technology, developed by a pioneering company committed to innovation and excellence in steel manufacturing, promises to revolutionize the industry. Designed to streamline the production process while reducing costs and enhancing product quality, this advanced roll forming machine is set to reshape the construction landscape.Streamlined Production Process:The Color Steel Roll Forming Machine automates and streamlines the manufacturing process for color steel rolls. It eliminates the need for manual labor, increasing both efficiency and productivity. With its fully automated operation, the machine can consistently produce high-quality, dimensionally accurate steel rolls at a significantly faster rate than traditional methods.Furthermore, this cutting-edge machine incorporates various advanced features such as automatic feeding, precision cutting, and accurate bending, ensuring a flawless end product. Additionally, it offers enhanced flexibility, allowing manufacturers to produce different profiles and sizes of color steel rolls as per customized requirements.Cost Efficiency and Reduced Waste:The Color Steel Roll Forming Machine is equipped with highly efficient energy-saving technologies. By optimizing power consumption and reducing material waste, it offers significant cost savings for manufacturers. The machine's ability to minimize production errors and material wastage ensures that each roll is utilized efficiently, thereby reducing overall expenses.Moreover, the advanced control system in the machine enables real-time monitoring and adjustment of production parameters. This not only enhances operational efficiency but also minimizes the need for manual intervention, further reducing labor costs.Environmental Sustainability:In line with the growing global focus on sustainability, the Color Steel Roll Forming Machine contributes to environmentally friendly manufacturing practices. Its energy-efficient design reduces carbon emissions and lowers the overall environmental footprint of the manufacturing process.Additionally, the machine's high precision and quality control mechanism ensure minimal material wastage, promoting sustainable resource management. By adopting this advanced technology, steel manufacturers can significantly reduce their impact on the environment and contribute to a greener future.Implications for the Steel Manufacturing Industry:The advent of the Color Steel Roll Forming Machine heralds a new era in the steel manufacturing industry. Its introduction is expected to bring about a multitude of benefits for manufacturers, contractors, and end-users alike.For manufacturers, the integration of this advanced technology allows for increased production capacity and reduced operational costs. The ability to produce a wide range of steel roll profiles opens up new market opportunities, catering to diverse customer demands.Contractors and construction firms benefit from the enhanced quality, precision, and efficiency of color steel rolls. These rolls, produced using the roll forming machine, exhibit superior durability, resistance to corrosion, and aesthetic appeal. The higher strength and reduced maintenance of color steel rolls significantly contribute to the longevity and sustainability of construction projects.Conclusion:The Color Steel Roll Forming Machine, developed by a leading company in steel manufacturing, represents a revolutionary leap forward in the industry. Its automated and efficient production process, coupled with cost-saving measures and environmental sustainability aspects, makes it the perfect solution for the evolving construction landscape.As more manufacturers integrate this advanced technology into their production lines, the steel manufacturing industry is poised to witness unparalleled growth and progress. The Color Steel Roll Forming Machine paves the way for a future where high-quality, sustainable, and economically viable construction materials become the norm, supporting the ever-growing infrastructure needs of our global society.

High-Quality Roll Forming Machines: Top Supplier and Manufacturer in China

Roll forming machines have been used in the construction and manufacturing industries for decades, particularly for producing profiles and panels that are used for roofing and cladding. There are different types of roll forming machines depending on the material being formed and the desired profile. Among these, the color steel roll forming machine is one of the most popular, especially for producing steel sheets in different colors.A color steel roll forming machine is a type of roll forming machine that is used to manufacture steel sheets in different colors. These machines are typically used for the production of sheets used for roofing and wall cladding, which are primarily used in the construction industry. The process of color steel roll forming involves feeding a coil of sheet metal through a series of rolls that shape the metal into the desired profile while applying a coating of paint or finishing material to the surface of the metal. The coating can be applied either before or after the forming process, depending on the type of machine being used.When it comes to purchasing a color steel roll forming machine, there are several factors to consider. First and foremost is the quality of the machine itself. A good machine will be made from high-quality materials and have a robust construction that ensures it can withstand the rigors of continuous operation. Additionally, the machine should be easy to operate and maintain, with user-friendly controls and clear documentation that makes it easy to troubleshoot any issues that may arise.Another important consideration when purchasing a color steel roll forming machine is the reputation of the manufacturer. There are many manufacturers of roll forming machines out there, but not all are created equal. Look for a manufacturer that has a good track record of producing high-quality machines, and that has positive reviews from other customers in the industry. This will give you confidence that you are getting a machine that will meet your needs and perform well over the long term.Finally, consider the price of the machine and how it fits into your budget. Color steel roll forming machines can be quite expensive, but there are many factors that can affect the price you pay, including the size and complexity of the machine, the materials used, and the quality of the components. Be sure to do your research and shop around to find the best value for your money.If you are in the market for a color steel roll forming machine, be sure to consider a reputable manufacturer like (brand name removed). With years of experience producing high-quality roll forming machinery, they have the expertise and know-how to help you select the perfect machine for your needs. Their range of products includes not only color steel roll forming machines but also a variety of other roll forming machines for a wide range of applications. So whether you need a machine for roofing, cladding, or other applications, they have you covered.In conclusion, a color steel roll forming machine is an essential tool for any construction or manufacturing business that needs to produce steel sheets in different colors. When shopping for a machine, it is important to consider quality, reputation, and price, and to choose a manufacturer that has a proven track record of producing high-quality machinery. So if you're in the market for a color steel roll forming machine, be sure to consider (brand name removed) and their range of high-quality products.

Metal Glazed Tile Roll Forming Machine for Colorful Roofing Sheets

and Glazed Tile Roll Forming Machine.Colored Metal Steel Sheet Roll Forming Machine and Glazed Tile Roll Forming MachineColored Roofing Steel Sheet Metal Glazed Tiles Forming Machine Roll Forming Machinery is a great investment for builders and contractors that specialize in roofing projects. This type of machinery is ideal for those who are looking for a cost-effective and efficient way to form roofing sheets and tiles.The Colored Metal Steel Sheet Roll Forming Machine and the Glazed Tile Roll Forming Machine are two types of machines that are commonly used in the roofing industry. These machines are designed to manufacture roofing sheets and tiles in different shapes and sizes, depending on the project requirements.The Colored Metal Steel Sheet Roll Forming Machine is a versatile piece of machinery that is used to form roofing sheets in various colors. The machine is designed to produce roofing sheets in a range of thicknesses, and it can be programmed to produce sheets in different lengths as well.The Glazed Tile Roll Forming Machine is another popular machine that is used in the roofing industry. This machine is specifically designed to produce glazed roofing tiles that are used for aesthetic purposes. The Glazed Tile Roll Forming Machine is ideal for builders and contractors who want to offer their clients a wide range of tile designs and colors.Both the Colored Metal Steel Sheet Roll Forming Machine and the Glazed Tile Roll Forming Machine are designed to offer high production rates and efficiency. These machines are user-friendly and require minimal maintenance. They are also designed to operate quietly, which is ideal for roofing projects that occur in residential areas.One of the biggest advantages of using a Colored Metal Steel Sheet Roll Forming Machine and a Glazed Tile Roll Forming Machine is the reduction of labor costs. These machines are designed to automate the process of forming roofing sheets and tiles, which eliminates the need for manual labor. This results in cost savings for builders and contractors, which can be passed on to their customers.When shopping for a Colored Metal Steel Sheet Roll Forming Machine or a Glazed Tile Roll Forming Machine, it is important to consider the material being used, the thickness of the material, the desired length and width of the roofing sheets or tiles, and the features of the machine. Different machines offer different features, such as adjustable forming speeds and customizable designs.In conclusion, the Colored Metal Steel Sheet Roll Forming Machine and the Glazed Tile Roll Forming Machine are two valuable pieces of machinery for builders and contractors in the roofing industry. They offer high production rates, efficiency, and cost savings. When investing in these machines, it is important to consider the needs and requirements of the project, as well as the features and capabilities of the machine.

High-Quality Rain Pipe Roll Forming Machine for Color Steel

Color Steel Rain Pipe Roll Forming Machine: Revolutionizing the Rainwater IndustryIn today's fast-paced world, technology and innovation are paramount in every industry. The rainwater system industry is no exception, and the introduction of the Color Steel Rain Pipe Roll Forming Machine has brought about a revolution in how rain pipes are manufactured. This state-of-the-art machine is the brainchild of the renowned company {} which has been a leading player in the roll forming machinery industry for over a decade.The Color Steel Rain Pipe Roll Forming machine is designed to produce high-quality, durable and efficient rain pipes. It is equipped with advanced technology and automation to ensure precision in forming and cutting the rain pipes. The machine is capable of handling a wide range of materials, including color steel, galvanized steel, and aluminum, thus catering to the diverse needs of the rainwater industry.One of the standout features of this machine is its versatility. It can produce rain pipes of various shapes and sizes, making it ideal for both residential and commercial applications. Additionally, the machine's high production speed and efficiency make it a cost-effective solution for rainwater system manufacturers.The company {} takes pride in the quality and reliability of its products. The Color Steel Rain Pipe Roll Forming Machine is no exception, as it undergoes rigorous testing and quality control measures to ensure that it meets the highest industry standards. This commitment to quality has earned {} a stellar reputation in the roll forming machinery industry, and the Color Steel Rain Pipe Roll Forming Machine is a testament to their dedication to excellence.Moreover, {} not only provides top-notch machinery but also offers comprehensive after-sales support and maintenance services. This ensures that their clients can maximize the potential of the Color Steel Rain Pipe Roll Forming Machine and maintain its optimal performance for years to come.The introduction of the Color Steel Rain Pipe Roll Forming Machine has certainly made a significant impact in the rainwater system industry. Its advanced technology, versatility, and superior quality have set a new benchmark in the manufacturing of rain pipes. With the growing emphasis on sustainable and efficient rainwater systems, this machine is well-positioned to meet the evolving needs of the industry.The Color Steel Rain Pipe Roll Forming Machine is a game-changer, and it is expected to revolutionize the way rain pipes are manufactured. Its impact will not only be felt in the rainwater system industry but also in various other sectors that rely on high-quality and efficient roll-formed products.In conclusion, the introduction of the Color Steel Rain Pipe Roll Forming Machine by {} marks a significant milestone in the rainwater system industry. Its cutting-edge technology, precision engineering, and commitment to quality have set it apart as a leader in the roll forming machinery industry. As the demand for sustainable rainwater solutions continues to grow, the Color Steel Rain Pipe Roll Forming Machine is well-positioned to meet the needs of manufacturers and contribute to a greener and more efficient future.

High-quality Color Steel Roll Forming Machine for GP/GI Steel Sheets

Introducing the GP GI Color Steel Roll Forming MachineIn the ever-evolving world of manufacturing, the demand for efficient and reliable roll forming machines is on the rise. Companies are constantly seeking innovative solutions to improve their production processes and meet the needs of their customers. It is in response to this demand that {Company Name} has introduced the GP GI Color Steel Roll Forming Machine – a state-of-the-art piece of equipment that promises to revolutionize the roll forming industry.{Company Name} has been a leading provider of roll forming solutions for over a decade. Their commitment to innovation and quality has earned them a reputation as a trusted partner for businesses across various industries. With the introduction of the GP GI Color Steel Roll Forming Machine, they aim to further solidify their position as a leader in the industry.The GP GI Color Steel Roll Forming Machine is designed to meet the diverse needs of modern manufacturing facilities. It is capable of producing high-quality color steel roll-formed products with a smooth finish and precise dimensions. The machine is equipped with advanced control systems that ensure consistent and accurate production, resulting in minimal material waste and increased efficiency.This roll forming machine is ideal for the production of a wide range of products, including roofing and wall panels, decking, and other structural components. Its versatility makes it a valuable asset for businesses looking to expand their product offerings and meet the demands of their customers.Furthermore, the GP GI Color Steel Roll Forming Machine is built with durability and reliability in mind. It is constructed with high-quality materials and components that can withstand the rigors of heavy-duty production. This ensures that businesses can rely on the machine to deliver consistent performance over the long term, minimizing downtime and maintenance costs.In addition to its technical capabilities, the GP GI Color Steel Roll Forming Machine is designed with user-friendliness in mind. It features intuitive controls and interface, making it easy for operators to set up and operate the machine with minimal training. This reduces the learning curve for new users and allows businesses to maximize the productivity of their workforce.{Company Name} is proud to offer comprehensive support and service for the GP GI Color Steel Roll Forming Machine. Their team of experienced professionals is available to provide installation, training, and ongoing maintenance to ensure that businesses can get the most out of their investment. This commitment to customer satisfaction sets {Company Name} apart as a trusted partner for businesses looking to enhance their production capabilities.With the introduction of the GP GI Color Steel Roll Forming Machine, {Company Name} continues to demonstrate their dedication to providing innovative solutions for the roll forming industry. As manufacturing trends and customer demands continue to evolve, businesses can rely on {Company Name} to deliver cutting-edge equipment that meets their needs and drives their success.In conclusion, the GP GI Color Steel Roll Forming Machine represents a significant advancement in the roll forming industry. Its advanced capabilities, durability, and user-friendly design make it a valuable asset for businesses seeking to enhance their production processes. With the support of {Company Name}, businesses can confidently invest in this state-of-the-art machine and position themselves for success in the competitive manufacturing landscape.

High-Quality Metal Roof Forming Machine: Glazed Tile Cold Forming Machin Color Steel Glazed Roofing Tile Making Machine Supplier - Buy Roof Panel Roll Forming Machine from China Factory

Metal Roof Forming Machine: Your Guide to Color Steel Profile Forming EquipmentAre you looking for a Metal Roof Forming Machine that is capable of producing high-quality Color Steel Glazed Roofing Tiles? If so, you've come to the right place. In this blog post, we will discuss everything you need to know about Metal Roof Forming Machine, Glazed Tile Cold Forming Machine, and Color Steel Profile Forming Equipment.Metal Roof Forming MachineA Metal Roof Forming Machine is a piece of equipment that is used to manufacture metal roof panels and sheets. This machine is highly efficient and can produce a large number of metal roof panels in a short amount of time. Metal Roof Forming Machines can be manual or automated, with the latter being more popular due to the reduced labor costs associated with it. The machine is designed to work with different types of metal, including aluminum, copper, and steel.Glazed Tile Cold Forming MachineA Glazed Tile Cold Forming Machine, on the other hand, is used to produce Glazed Tiles from metal sheets. This machine is designed to work with different types of metals, including aluminum, steel, and copper. The Glazed Tile Cold Forming Machine uses a process called cold forming to shape the metal sheets into the desired shape for the tiles. This process is highly efficient and produces high-quality glazed tiles that are ideal for roofing.Color Steel Profile Forming EquipmentColor Steel Profile Forming Equipment is a type of machine that is used to manufacture Color Steel Profile Sheets. This machine is highly efficient and can produce a large number of sheets in a short amount of time. The machine is designed to work with different types of metal sheets, including aluminum, copper, and steel. Color Steel Profile Forming Equipment is highly versatile, making it suitable for use in different industries, including construction, automotive, and manufacturing.Importance of Metal Roof Forming MachinesMetal Roof Forming Machines are essential for any metal roofing company. These machines make it possible to produce high-quality roof panels and sheets in large quantities. Metal roofing companies can use Metal Roof Forming Machines to improve their productivity and profitability. Moreover, these machines are designed to work with different types of metals, making them suitable for use in different industries.Benefits of Glazed Tile Cold Forming MachinesGlazed Tile Cold Forming Machines are essential for making high-quality glazed tiles for roofing. These machines are highly efficient and produce high-quality glazed tiles that are resistant to weathering and other damages. Glazed Tile Cold Forming Machines are easy to use and are highly reliable, making them suitable for use in different industries.Advantages of Color Steel Profile Forming EquipmentColor Steel Profile Forming Equipment is highly versatile and can be used to produce different types of Color Steel Profile Sheets. These machines are highly efficient and can produce a large number of sheets in a short amount of time. Additionally, Color Steel Profile Forming Equipment is easy to operate and maintain, making it a favorite of many industries.ConclusionMetal Roof Forming Machine, Glazed Tile Cold Forming Machine, and Color Steel Profile Forming Equipment are essential for any industry that uses metal sheets. These machines are highly efficient, reliable, and versatile, making them suitable for use in different industries. If you're looking for a Metal Roof Forming Machine capable of producing high-quality Color Steel Glazed Roofing Tiles, you need to consider investing in a Glazed Tile Cold Forming Machine. Similarly, if you need to produce Color Steel Profile Sheets, you should invest in Color Steel Profile Forming Equipment.

High-Quality Steel Profile Manufacturing Machine for Your Business

Color Steel Profile Manufacturing Machine Revolutionizes the Building IndustryThe construction industry is always looking for innovative and efficient ways to produce building materials, and the latest advancement comes in the form of the Color Steel Profile Manufacturing Machine. This revolutionary machine is set to transform the way color steel profiles are produced, making the process faster, more precise, and more cost-effective than ever before.The Color Steel Profile Manufacturing Machine, developed by a leading manufacturer in the industry, is designed to meet the growing demand for high-quality color steel profiles. These profiles are essential components in modern construction, used in roofing, cladding, and structural applications. With the construction industry booming worldwide, there is a need for a reliable and efficient method of producing color steel profiles to meet this increasing demand.The newly developed machine integrates cutting-edge technology and advanced manufacturing processes to streamline the production of color steel profiles. It is capable of producing a wide range of profiles with different shapes, sizes, and colors, giving builders and architects the flexibility they need to bring their designs to life. The machine can also produce profiles with various coating options, providing durability and weather resistance for use in different environments.One of the key features of the Color Steel Profile Manufacturing Machine is its high level of automation. This not only increases the speed of production but also ensures consistent quality in every profile that is manufactured. The machine is equipped with precision tools and sensors that monitor the production process in real-time, allowing for adjustments to be made as needed to maintain quality and accuracy.Furthermore, the machine is designed with efficiency in mind, optimizing material usage and minimizing waste. This not only reduces production costs but also makes the manufacturing process more sustainable, aligning with the increasing focus on environmental responsibility in the construction industry.In addition to its advanced capabilities, the Color Steel Profile Manufacturing Machine is also designed for ease of use. It can be operated by a minimal number of skilled workers, reducing the need for extensive training and labor costs. The intuitive interface and user-friendly controls make it accessible to a wide range of operators, further enhancing its versatility and practicality.The introduction of this innovative machine is a significant milestone for the company and the industry as a whole. With its potential to revolutionize the production of color steel profiles, it is sure to have a profound impact on the construction sector. Architects, contractors, and developers will benefit from the increased efficiency and quality that this machine offers, ultimately leading to higher standards in building construction.The company, which has a solid reputation for delivering cutting-edge solutions to the construction industry, has once again demonstrated its commitment to innovation and excellence. With a strong focus on research and development, it has been able to stay ahead of the curve and anticipate the evolving needs of the market. The Color Steel Profile Manufacturing Machine is a testament to the company's dedication to providing state-of-the-art solutions that enable its customers to thrive in a competitive industry.Looking ahead, the company is poised to continue its leadership in the manufacturing of construction materials, leveraging its expertise and resources to drive further advancements in the field. As the demand for sustainable, high-performance building materials continues to grow, the company is well-positioned to play a pivotal role in shaping the future of construction.In conclusion, the Color Steel Profile Manufacturing Machine represents a significant leap forward for the construction industry. Its advanced technology, efficiency, and quality standards are set to transform the way color steel profiles are produced, setting a new benchmark for the sector. This innovation underscores the company's commitment to driving progress and delivering value to its customers, and it is sure to make a lasting impact on the built environment.

Upcoming Advancements in Steel Profile Forming Equipment: Enhancing Efficiency and Precision

Color Steel Profile Forming Equipment Revolutionizes the Construction IndustryThe construction industry has been transformed by the introduction of innovative and technologically advanced equipment. One of the most significant additions in recent years is the Color Steel Profile Forming Equipment. This machine has revolutionized the way construction professionals manufacture and install roofing and wall cladding systems in their projects.This state-of-the-art equipment is used to roll-form various special-shaped steel profiles that can be used in walls, ceilings, and roofs. The equipment uses a series of rollers to transform flat metal sheets into complex profiles with minimal labor. This is an ideal solution for businesses looking for a durable, cost-effective, and efficient way of cladding the exterior or interior of their structures.The Color Steel Profile Forming Equipment is versatile and can be customized to produce different profiles depending on the specifications of the project. This flexibility in design allows builders and architects to create curved, angular, and geometric shapes that were once thought impossible to achieve with conventional steel materials. The machine can be programmed to produce profiles of various thicknesses, colors, and coatings, which gives builders and architects more options to meet their specific needs.In addition, the Color Steel Profile Forming Equipment has increased the speed and precision of profile production. The equipment utilizes computer-controlled systems to ensure consistent quality throughout the production cycle, which significantly reduces the risk of deformation, cracks, or inconsistencies that can occur during manual cladding installation. With the use of this advanced equipment, construction professionals can produce more profiles in a shorter period of time and with less waste.Moreover, the use of this equipment is environmentally friendly, as it greatly reduces the amount of scrap metal and waste generated during production. This material efficiency leads to lower costs and better compliance with environmental regulations, which is essential for businesses operating in the construction industry.While the initial cost of the Color Steel Profile Forming Equipment may be high for small construction firms, its benefits far outweigh the investment in the long run. This equipment has revolutionized the construction industry by increasing efficiency, reducing material wastage, and providing builders with more flexibility in design. It has helped businesses to deliver projects that meet the highest quality standards, with a shorter production cycle and at a lower cost.This equipment is manufactured by a renowned company that specializes in the production of high-quality color steel profile forming equipment. This company has a strong reputation for producing top-of-the-range equipment that is used worldwide in various construction applications. Their equipment is optimized for durability, precision, and ease of use, making it the preferred choice for construction professionals who seek reliable and efficient solutions.This company has been in operation for over 20 years and has gained substantial experience in producing custom-made equipment that meets the unique requirements of different construction projects. They offer their clients professional advice on how to optimize their production processes, reduce production costs, and increase their competitiveness. Their focus on quality, innovation, and reliability has enabled them to become a global leader in the manufacturing of color steel profile forming equipment.In conclusion, the Color Steel Profile Forming Equipment has transformed the construction industry by providing businesses with a faster, more efficient, and cost-effective way of cladding their structures. Its versatility, precision, and material efficiency have made it the preferred choice for builders and architects who seek to meet the highest quality standards while keeping their costs low. With a reputable company specializing in the production of this equipment, businesses can invest in this technology with confidence, knowing that it will help them to remain competitive in today's construction market.

Steel Roofing Machine - Advanced Automation & Easy Maintenance

Title: The Advancements in Roll Forming Machine Technology Revolutionize Steel Roofing ProductionIntroduction:The global construction industry has witnessed significant growth in recent years, creating a high demand for reliable and efficient machinery for manufacturing steel roofing. In response to this demand, roll forming machine manufacturers have developed state-of-the-art technology that is set to revolutionize the steel roofing production process. This article explores the latest advancements in roll forming machines, focusing on the benefits they offer, including enhanced automation, ease of use, and improved efficiency.Enhanced Automation and Information Management:One of the most notable features of the latest roll forming machines is their integration of high-level automatic control software, enabling advanced production information management. This level of automation not only streamlines the manufacturing process but also provides real-time monitoring and data analysis, allowing for better quality control and increased productivity. The use of a highly integrated network in the entire unit automation control system ensures optimum performance and efficient operations.Improved Operation and Maintenance:The newly developed roll forming machines have undergone significant enhancements to make them more user-friendly. With improved operation controls, these machines are now easier to operate, ensuring operators can quickly adapt to the technology. Additionally, the maintenance and mechanical debugging processes have been simplified, reducing downtime and improving overall efficiency. These advancements empower manufacturers to take full control of their production line and minimize the need for extensive technical know-how.Efficient Mold Replacement:The ability to quickly and easily replace molds is crucial in the steel roofing production process. Roll forming machines now offer streamlined mold replacement procedures, allowing for rapid and hassle-free transitions between different roofing profiles. This capability not only minimizes downtime but also expands the range of products that can be manufactured, providing manufacturers with increased flexibility and market adaptability.Case Study: Color Steel Roofing Roll Forming Machine[Company Name], a leading roll forming machine manufacturer, has successfully developed and launched an innovative Color Steel Roofing Roll Forming Machine. This advanced equipment combines cutting-edge technology with user-friendly features, further revolutionizing steel roofing production.The Color Steel Roofing Roll Forming Machine incorporates the latest automation control software, enabling manufacturers to easily manage and monitor the entire production process. With the highly integrated network, operators can ensure the smooth performance of the automated system, increase efficiency, and achieve superior results.The machine's intuitive operation controls, along with simplified maintenance and mechanical debugging processes, allow for seamless and uninterrupted production. Operators can swiftly adapt to the technology, speeding up the learning curve and reducing the possibility of errors.Furthermore, the Color Steel Roofing Roll Forming Machine offers a revolutionary mold replacement system. The quick and easy mold replacement process enhances production flexibility, enabling manufacturers to respond promptly to changing market demands. This unique feature not only broadens the scope of products but also helps businesses remain competitive in the dynamic steel roofing industry.Conclusion:The recent advancements in roll forming machine technology, including the Color Steel Roofing Roll Forming Machine, are transforming the steel roofing production industry. With enhanced automation, simplified operation and maintenance processes, and efficient mold replacement capabilities, these machines streamline the manufacturing process, improve efficiency, and increase productivity. As the demand for steel roofing continues to rise, the integration of advanced roll forming machines will play a pivotal role in meeting market requirements and staying ahead of the competition.