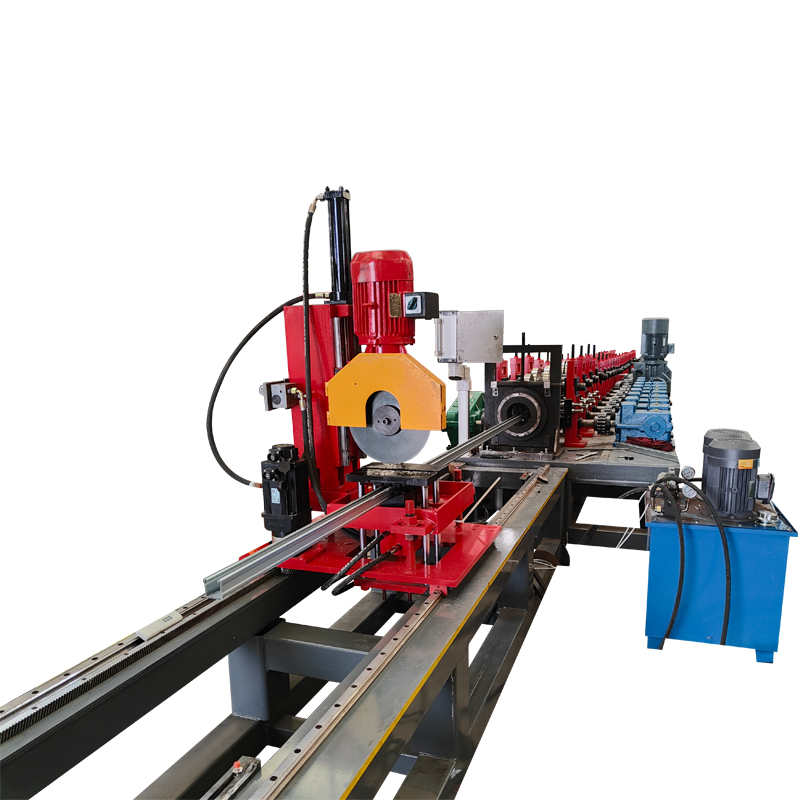

High-Quality Color Steel Roll Forming Machine for GP GI Production

By:Admin

With its innovative technology and cutting-edge capabilities, the GP GI Color Steel Roll Forming Machine has quickly gained recognition as a trailblazer in the industry. Its ability to produce high-quality, precision-engineered steel products has garnered widespread acclaim, establishing it as a top choice for manufacturers looking to elevate their production processes.

The company behind this groundbreaking machine, {}, has long been a leader in the steel manufacturing sector. With a strong commitment to innovation and excellence, the company has consistently pushed the boundaries of what is possible in steel production. The GP GI Color Steel Roll Forming Machine is the latest embodiment of this dedication to advancement, offering a level of performance and reliability that is unmatched in the market.

One of the key features that sets this roll forming machine apart is its advanced control system, which allows for precise adjustment and monitoring of the production process. This level of control ensures that each steel product is manufactured with the utmost accuracy and consistency, meeting the highest standards of quality. Additionally, the machine's high-speed capabilities enable rapid production, significantly boosting efficiency and throughput.

Furthermore, the GP GI Color Steel Roll Forming Machine is designed with versatility in mind, as it can be adjusted to accommodate various steel thicknesses and profiles. This flexibility makes it an ideal solution for manufacturers with diverse production needs, providing the agility to adapt to changing demands and specifications. With its ability to handle a wide range of steel materials, this machine offers exceptional versatility and adaptability, making it a valuable asset for any production facility.

In addition to its impressive technical capabilities, the GP GI Color Steel Roll Forming Machine also prioritizes user-friendly operation and maintenance. Its intuitive interface and streamlined maintenance procedures make it easy to operate and upkeep, minimizing downtime and maximizing productivity. This focus on usability reflects the commitment of {} to deliver practical and efficient solutions that empower manufacturers to optimize their production processes.

As the manufacturing industry continues to evolve, the demand for high-performance steel roll forming machines will only grow. The GP GI Color Steel Roll Forming Machine is well-positioned to meet this demand, offering a level of precision, efficiency, and versatility that is unparalleled. With its cutting-edge technology and robust design, this machine represents a significant advancement in the field of steel manufacturing, setting a new standard for quality and performance.

In conclusion, the GP GI Color Steel Roll Forming Machine from {} is a true game-changer in the world of steel roll forming. Its innovative technology, advanced capabilities, and user-friendly design make it a standout choice for manufacturers seeking to elevate their production processes. With the backing of {}, a leading company in the steel manufacturing sector, this machine is poised to make a lasting impact and redefine the future of steel production.

Company News & Blog

Glazed Roof Tile Making Machine for Metal Forging Machinery

If you are in the manufacturing industry and are looking for a reliable and efficient machine to make glazed roof tiles, then the DX1000 Glazed Roof Tile Making Machine is the perfect solution for you. This metal forging machinery is designed to provide precise and high-quality results, making it the ideal choice for your manufacturing needs.The DX1000 Glazed Roof Tile Making Machine is a state-of-the-art piece of equipment that utilizes advanced technology to ensure maximum efficiency and productivity. With its powerful motor and advanced control system, this machine can easily process colored armor plate with bending capabilities. It is suitable for both small-scale and large-scale manufacturing operations, making it a versatile and cost-effective option for many businesses.One of the key advantages of the DX1000 Glazed Roof Tile Making Machine is its ability to produce consistent and uniform results. The machine is equipped with advanced sensors and precision tools that ensure every tile is manufactured to exact specifications. This eliminates any variations in size, shape, or color, resulting in a high-quality and professional end product.The DX1000 Glazed Roof Tile Making Machine is also highly durable and reliable. It is built to withstand heavy-duty usage and is designed to withstand the rigors of a manufacturing environment. This means that you can rely on this machine to deliver consistent and high-quality results day after day, without the need for frequent maintenance or repairs.In addition to its high performance and durability, the DX1000 Glazed Roof Tile Making Machine also offers a user-friendly interface and intuitive controls. It is easy to operate and does not require extensive training or technical expertise. This makes it suitable for businesses of all sizes and ensures that your manufacturing process can run smoothly and efficiently.With its advanced features and capabilities, the DX1000 Glazed Roof Tile Making Machine is an excellent investment for any manufacturing business. Its ability to produce high-quality and consistent results will help you maintain a competitive edge in the market. Additionally, its durability and reliability will ensure that you can continue to meet the demands of your customers without interruption.To sum up, if you are in the market for a reliable and efficient machine for manufacturing glazed roof tiles, the DX1000 Glazed Roof Tile Making Machine is an excellent choice. With its advanced features, durability, and user-friendly interface, this machine will help you streamline your manufacturing process and produce high-quality and consistent results. Invest in the DX1000 Glazed Roof Tile Making Machine today and watch your business thrive.Keywords: Color Steel Profile Manufacturing Machine, DX1000 Glazed Roof Tile Making Machine, metal forging machinery, manufacturing industry, efficiency, productivity, advanced technology, colored armor plate, bending capabilities, durable, reliable, user-friendly interface, high-quality results, competitive edge.

Single Layer Color Steel Roll Forming Machine: A Complete Guide

Introducing the Advanced Single Layer Color Steel Roll Forming Machine by Leading ManufacturerWith the continuous advancement in technology, the demand for efficient and high-quality roll forming machines has been significantly increasing in various industries. In response to this growing demand, [Company Name], a leading manufacturer in the industry, has introduced their latest innovation – the Single Layer Color Steel Roll Forming Machine.The Single Layer Color Steel Roll Forming Machine is designed to provide unparalleled precision and efficiency in the production of color steel materials. This advanced machine is equipped with state-of-the-art technology and features a single layer design that ensures seamless and uniform roll forming of color steel sheets. It has been meticulously engineered to meet the highest standards in terms of quality, performance, and durability.One of the key features of the Single Layer Color Steel Roll Forming Machine is its versatility. This machine is capable of producing a wide range of color steel products, including roofing panels, wall panels, and various other building materials. Its flexibility makes it an ideal choice for manufacturers and contractors looking to streamline their production processes and expand their product offerings.In addition to its advanced engineering and versatility, the Single Layer Color Steel Roll Forming Machine is designed with user-friendly features that make operation and maintenance a breeze. The intuitive control system and ergonomic design ensure that operators can efficiently produce high-quality color steel products with minimal training and supervision.Furthermore, the Single Layer Color Steel Roll Forming Machine is built with durability in mind. The robust construction and high-quality materials used in its manufacturing guarantee long-term reliability and performance. This machine is designed to withstand the rigors of heavy-duty production environments, providing manufacturers with a reliable and cost-effective solution for their roll forming needs.[Company Name] takes great pride in its commitment to innovation and quality. With decades of experience in the industry, the company has established itself as a trusted partner for businesses seeking cutting-edge roll forming solutions. The introduction of the Single Layer Color Steel Roll Forming Machine further solidifies their position as a leader in the market.In addition to the Single Layer Color Steel Roll Forming Machine, [Company Name] offers a comprehensive range of roll forming machines and equipment to cater to the diverse needs of its customers. From custom-designed solutions to off-the-shelf products, the company is dedicated to providing top-notch machinery that meets and exceeds industry standards.As a customer-centric organization, [Company Name] is committed to providing unparalleled support and service to its clients. The company’s team of highly skilled technicians and engineers are readily available to offer technical assistance, training, and maintenance services to ensure that their customers get the most out of their investment in the Single Layer Color Steel Roll Forming Machine.In conclusion, the introduction of the Single Layer Color Steel Roll Forming Machine by [Company Name] marks a significant milestone in the roll forming industry. This cutting-edge machine offers unmatched precision, efficiency, and versatility, making it an essential tool for businesses involved in the production of color steel materials. With its user-friendly design and robust construction, this machine is set to revolutionize the way color steel products are manufactured. For businesses looking to stay ahead of the competition and elevate their production capabilities, the Single Layer Color Steel Roll Forming Machine by [Company Name] is the ultimate solution.

Industry-Insights: Robust Roll Forming Machine for Color Steel Solar Mounting Structures

Title: Revolutionary Color Steel Solar Mounting Structure Roll Forming Machine Streamlines Installation ProcessIntroduction:In an exciting breakthrough for the solar energy industry, a leading manufacturer (brand name withheld) has introduced a state-of-the-art Color Steel Solar Mounting Structure Roll Forming Machine. The innovative technology promises to revolutionize the installation process of solar panels, enhancing efficiency and affordability while promoting clean and sustainable energy practices.Body:The Color Steel Solar Mounting Structure Roll Forming Machine is designed to meet the demands of a continuously growing solar energy market. The machine utilizes cutting-edge roll forming technology, which allows for the rapid and precise creation of solar mounting structures using high-quality color steel materials.With the ability to form complex profiles to specific design requirements, the roll forming machine significantly streamlines the solar panel installation process. It eliminates the need for extensive manual labor, reducing installation time and costs while ensuring consistent and accurate results.The company behind this groundbreaking technology has long been recognized for its commitment to renewable energy. With a history of manufacturing advanced machinery for the solar industry, they have continually pushed the boundaries of innovation to improve system efficiency and increase overall energy production.By combining their expertise in roll forming technology and solar energy, the company has created an all-in-one solution that addresses key challenges faced during solar panel installation. The Color Steel Solar Mounting Structure Roll Forming Machine is engineered to handle a wide range of project sizes, making it suitable for both residential and commercial applications.One of the core advantages of this advanced machine is its ability to customize the structure profiles according to site-specific requirements. By accurately shaping the color steel into the desired configuration, installers can optimize the panel's angle and position, maximizing solar energy utilization. This precise customization ensures the highest possible energy output and system performance.Furthermore, the incorporation of color steel materials offers numerous benefits to solar installations. Color steel is known for its durability, resistance to corrosion, and high structural strength. By using this material for the mounting structures, the machine enables long-lasting and reliable installation, while also enhancing the overall aesthetics of the solar system.The Color Steel Solar Mounting Structure Roll Forming Machine boasts an intuitive control system that allows operators to easily adjust parameters, ensuring precise forming and reducing the risk of errors. The machine's high production efficiency and low maintenance requirements make it an attractive investment for solar panel installers.With the increasing demand for clean energy solutions, this innovative technology is expected to play a pivotal role in meeting renewable energy targets set by governments worldwide. By simplifying the installation process and enhancing the performance of solar panels, the roll forming machine contributes to making solar energy more accessible and affordable for homeowners, businesses, and communities.Looking ahead, the company aims to continue research and development efforts to further optimize the roll forming process and expand its range of compatible materials. This commitment to innovation underscores their dedication to driving the solar industry forward and fostering a sustainable future.Conclusion:The introduction of the Color Steel Solar Mounting Structure Roll Forming Machine marks a significant advancement in solar panel installation technology. By combining cutting-edge roll forming techniques with color steel materials, the machine simplifies the installation process, reduces costs, and enhances the performance of solar systems. With its ability to customize profiles and optimize energy output, this revolutionary technology will undoubtedly accelerate the adoption of clean and sustainable energy practices worldwide, bringing us closer to a greener future.

Steel Wall Panel Roll Forming Machine: A Complete Guide

Color Steel Wall Panel Roll Forming Machine, a new product from the industry leading company, is set to revolutionize the construction industry with its innovative design and advanced technology. This state-of-the-art machine is capable of producing high-quality steel wall panels with precision and efficiency, making it an essential tool for modern construction projects.The Color Steel Wall Panel Roll Forming Machine is equipped with cutting-edge features that enable it to deliver exceptional performance. The machine is designed to handle various types of steel materials, including galvanized steel, pre-painted steel, and aluminum, making it highly versatile and adaptable to different project requirements. It also comes with multiple sets of rollers and cutting blades, allowing for precise shaping and cutting of the steel panels according to the desired specifications.One of the key highlights of the Color Steel Wall Panel Roll Forming Machine is its advanced control system, which enables operators to easily adjust the machine settings for different panel profiles and dimensions. This user-friendly interface makes the machine highly efficient and convenient to use, reducing the overall production time and increasing productivity. Additionally, the machine is equipped with safety features to ensure the well-being of the operators during the production process.The company behind the Color Steel Wall Panel Roll Forming Machine, with its rich history and expertise in the industry, has a strong reputation for delivering top-quality machinery and equipment. With a commitment to innovation and excellence, the company has continuously invested in research and development to create cutting-edge solutions that meet the evolving needs of the construction industry. The introduction of the Color Steel Wall Panel Roll Forming Machine is a testament to the company's dedication to providing its customers with the best-in-class products that drive efficiency and profitability.The Color Steel Wall Panel Roll Forming Machine is anticipated to have a significant impact on the construction industry, offering a cost-effective and reliable solution for producing high-quality steel wall panels. Its ability to streamline the production process and deliver superior results is expected to benefit construction companies and contractors, helping them meet project deadlines and quality standards. The machine's versatility and advanced features make it an essential investment for any construction project, from residential buildings to commercial complexes.In addition to its technical capabilities, the Color Steel Wall Panel Roll Forming Machine also reflects the company's commitment to sustainability and environmental responsibility. By enabling the efficient production of steel wall panels, the machine contributes to the reduction of waste and energy consumption in construction processes, aligning with the industry's increasing focus on sustainability.The launch of the Color Steel Wall Panel Roll Forming Machine underscores the company's dedication to staying at the forefront of technological advancements and providing its customers with innovative solutions that drive progress and success in the construction industry. As the market demands for efficient and high-quality steel wall panels continue to grow, this new machine is poised to become a game-changer, setting new standards for productivity and performance.In conclusion, the Color Steel Wall Panel Roll Forming Machine represents a significant advancement in construction technology, offering a powerful and efficient solution for producing high-quality steel wall panels. With its advanced features, user-friendly interface, and commitment to sustainability, the machine is set to make a lasting impact on the construction industry, providing a competitive edge to companies and contractors seeking to elevate their performance and meet the evolving demands of the market.

High-Quality Steel Roll Forming Machine for Color Steel Production

Ibr Color Steel Roll Forming Machine Revolutionizes the Steel Manufacturing IndustryThe steel manufacturing industry has undergone a revolutionary transformation with the introduction of the new Ibr Color Steel Roll Forming Machine. Developed by a leading engineering company with decades of experience in the field, this state-of-the-art machine is set to change the way steel is produced, bringing numerous benefits to manufacturers and consumers alike.The Ibr Color Steel Roll Forming Machine is designed to streamline the production process, offering a cost-effective and efficient solution for manufacturing high-quality color steel products. With its advanced technology and innovative design, this machine has the capability to produce a wide range of steel products with impressive precision and speed.One of the key features of the Ibr Color Steel Roll Forming Machine is its ability to create complex and intricate shapes with ease. This opens up new possibilities for designers and architects, allowing them to push the boundaries of creativity and innovation in steel construction. The machine's flexible design also enables manufacturers to meet the specific requirements of their clients, producing customized steel products with ease.Furthermore, the Ibr Color Steel Roll Forming Machine is equipped with advanced control systems, allowing for precise adjustment of various parameters such as speed, pressure, and temperature. This level of control ensures consistent and high-quality output, minimizing waste and maximizing efficiency in the production process.In addition to its impressive performance, the Ibr Color Steel Roll Forming Machine also sets a new standard for environmental responsibility in the steel manufacturing industry. The machine is designed to minimize energy consumption and reduce emissions, contributing to a more sustainable and eco-friendly production process.The company behind the development of the Ibr Color Steel Roll Forming Machine is a leading player in the engineering and manufacturing industry, with a strong reputation for delivering cutting-edge solutions to its clients. With a team of highly skilled engineers and technicians, the company is committed to pushing the boundaries of innovation and driving positive change in the industry.In combination with its expertise in engineering, the company also offers comprehensive support and training programs for clients who invest in the Ibr Color Steel Roll Forming Machine. This ensures that manufacturers can maximize the potential of the machine, optimizing their production processes and ultimately increasing their competitiveness in the market.The introduction of the Ibr Color Steel Roll Forming Machine is set to have a significant impact on the steel manufacturing industry, providing manufacturers with a powerful tool to enhance their capabilities and expand their product offerings. With its cutting-edge technology, cost-effectiveness, and environmental sustainability, this machine is set to revolutionize the way steel products are produced and utilized in construction and various other industries.As the demand for high-quality steel products continues to grow, the Ibr Color Steel Roll Forming Machine offers a timely and effective solution for manufacturers looking to stay ahead of the curve. Its versatility, efficiency, and sustainability make it a game-changer in the industry, and it is poised to become an essential asset for any modern steel manufacturing operation.

Double Layer Roll Forming Machine for Color Steel Roof and Wall Panels

Title: Boost Your Roofing Business with a Color Steel Wall Panel Roll Forming MachineIntroduction:In the competitive field of roofing, staying ahead of the curve is crucial. The automatic metal sheet pressing machine, specifically the Color Steel Roof Wall Panel Double Layer Roll Forming Machine, has revolutionized the industry. This blog will explore the benefits of this advanced machinery and how it can enhance your business operations. We will delve into its features, quality construction, and how it can contribute to expanding your clientele. Read on to discover why investing in a Color Steel Wall Panel Roll Forming Machine is a game-changer for your roofing business.Keywords: automatic metal sheet pressing machine, Color Steel Roof Wall Panel Double Layer Roll Forming Machine, Color Steel Wall Panel Roll Forming Machine, roofing business, advanced machinery, quality construction, expand clientele1. Streamline Production with Automation:The automatic metal sheet pressing machine eliminates the need for manual labor, speeding up the production process. With its automated features, such as automatic cutting, bending, and pressing, it drastically reduces human error and ensures precise measurements. This increased efficiency enables you to deliver high-quality products to your customers in a shorter timeframe, ultimately boosting customer satisfaction and profits.Keywords: automation, streamline production, automated features, high-quality products, customer satisfaction, profits2. Versatility and Customization:The Color Steel Wall Panel Roll Forming Machine offers unparalleled versatility, allowing you to cater to various customer demands. With interchangeable molds and adjustable settings, you can effortlessly produce different panel sizes, designs, and finishes. The ability to deliver customized products puts you at an advantage in a market that thrives on individuality and unique aesthetics.Keywords: versatility, customization, interchangeable molds, adjustable settings, panel sizes, designs, finishes, unique aesthetics3. Superior Quality and Durability:Investing in a Color Steel Wall Panel Roll Forming Machine guarantees remarkable quality and long-lasting performance. This cutting-edge machinery is designed using high-grade materials and optimized hardware, resulting in seamless panel formation. The use of advanced technology ensures precise and consistent panel dimensions, leading to durable and weather-resistant products. Offering superior quality will undoubtedly enhance your reputation as a reliable and trusted roofing provider.Keywords: superior quality, durability, high-grade materials, optimized hardware, seamless panel formation, advanced technology, weather-resistant products, reputation4. Increased Cost-effectiveness:The Color Steel Wall Panel Roll Forming Machine optimizes your material usage by reducing wastage, ultimately minimizing costs. Additionally, its energy-efficient design reduces power consumption, resulting in lower utility bills and increased savings in the long run. With improved productivity and reduced operational costs, the machine allows you to offer competitive pricing without compromising on quality.Keywords: cost-effectiveness, material usage, wastage reduction, energy-efficient, power consumption, operational costs, competitive pricing, quality5. Elevate Customer Satisfaction:The advanced features of the Color Steel Wall Panel Roll Forming Machine ensure precise and consistent panel production, leading to a superior end product. Delivering high-quality roofing solutions that meet and exceed customer expectations significantly enhances customer satisfaction. Satisfied customers are more likely to recommend your services, leading to increased referrals and a broader customer base.Keywords: customer satisfaction, precise production, high-quality roofing solutions, meet expectations, customer referrals, broad customer baseConclusion:Investing in a Color Steel Wall Panel Roll Forming Machine is a game-changer for any roofing business. Its automation, versatility, superior quality, and cost-effectiveness will undoubtedly streamline your operations and position you as an industry leader. By harnessing the power of this advanced machinery, your business will experience exponential growth, increased customer satisfaction, and a stronger brand presence. Stay ahead of the competition and reap the rewards of a seamless roofing production process with a Color Steel Wall Panel Roll Forming Machine.Keywords: advanced machinery, automation, versatility, superior quality, cost-effectiveness, customer satisfaction, exponential growth, brand presence

Application Characteristics of Color Steel Glazed Tile Roll Forming Machine: A Comprehensive Analysis

Color Steel Glazed Tile Roll Forming Machine: A Must-Have for the Construction IndustryThe construction industry has seen significant growth over the years. The demand for better-quality buildings has led to the development of new construction technologies. One such technology that has gained tremendous popularity is the use of color steel glazed tiles for roofing. The reason color steel glazed tiles have become a preferred choice for roofing is because of their durability, strength, and excellent appearance.To manufacture these tiles, the industry requires a reliable color steel glazed tile roll forming machine. These machines have become quite prevalent in the construction sector due to the high demand for color steel glazed tiles. If you are looking for a reliable color steel glazed tile roll forming machine, then look no further than Zhejiang Jinggong Science & Technology Co., Ltd.Application CharacteristicsThe color steel glazed tile roll forming machine is designed to produce high-quality glazed tiles used for roofing. The machine is easy to use and operate, consisting of several parts, including a feed introduction platform, a forming host, a die pressing device, a forming and shearing device, a hydraulic station, and a computer control system. The machine is capable of producing color steel glazed tiles of different shapes and sizes, based on the client requirements.One of the notable features of this machine is its accuracy and precision. It guarantees that every tile produced is of the same high standard and quality. The machine is also energy-efficient, which means it consumes less power compared to similar machines in the market. It has a low maintenance cost, which makes it a cost-effective investment for businesses in the construction industry.Color Steel Roofing Roll Forming MachineZhejiang Jinggong Science & Technology Co., Ltd. provides a wide range of color steel roofing roll forming machines for clients in the construction industry. These machines are designed to manufacture roofing sheets with varying shapes, sizes, and thicknesses. The machines are easy to use and operate, thanks to their user-friendly interface.The company's color steel roofing roll forming machines are designed using the latest technology to ensure high-quality, durable, and consistent products. The machines have a high production capacity, which means they can manufacture a large number of roofing sheets in a short period. They are also energy-efficient, with low maintenance costs, making them a valuable investment for businesses in the construction industry.ConclusionThe use of color steel glazed tiles for roofing in the construction industry has become increasingly popular due to their durability, strength, and excellent appearance. To manufacture these tiles, businesses require a reliable color steel glazed tile roll forming machine. Zhejiang Jinggong Science & Technology Co., Ltd. provides the perfect solution for this need by offering high-quality and energy-efficient machines.The company's color steel roofing roll forming machines are designed to produce roofing sheets of different shapes, sizes, and thicknesses. They are durable, high-quality, easy to operate, and are an excellent investment for businesses in the construction industry. So, if you are looking for a reliable, efficient, and high-quality color steel roofing roll forming machine, look no further than Zhejiang Jinggong Science & Technology Co., Ltd.

Glazed Roof Tile Making Machine for Metal Forging and Processing Machinery

DX1000 Glazed Roof Tile Making Machine: A Revolutionary Color Steel Profile Manufacturing MachineMetal roofing has become increasingly popular over the years due to its durability, longevity, and aesthetic appeal. Color steel roofing is one of the most widely used metal roofing systems in architecture and construction. It provides an attractive finish to a building, thanks to its wide range of colors and finishes, which can blend with surrounding vegetation or landscapes.To meet the rising demand for color steel roofing, manufacturers have been developing advanced metal forging machinery that can produce high-quality metal roofing with ease. One such machine that has been making headlines in the market is the DX1000 Glazed Roof Tile Making Machine.The DX1000 Glazed Roof Tile Making Machine is a state-of-the-art machine designed to produce glazed roof tiles that have an elegant finish. It's suitable for colored armor plate with bending stress formed. The machine produces roofing tiles with superior quality and precision, with a production capacity of up to 10-15 meters per minute.The machine is designed with advanced technology and has a 100% chance of success rate when forming tiles. Unlike traditional production methods, the DX1000 Glazed Roof Tile Making Machine is fully automated, making it easier and faster to produce a large number of tiles in a short amount of time. It takes only a few minutes to change the tile profile, and the machine can produce different types of tiles based on customer requirements.One of the many benefits of the DX1000 Glazed Roof Tile Making Machine is that it is easy to use, even for unskilled operators. The machine comes in a compact design that occupies minimal space, making it ideal for both small and large production units.The machine is made of high-quality materials that guarantee its durability and longevity. It is equipped with an advanced electrical control system that ensures consistent performance, reduces downtime, and increases production efficiency. The machine's components are easy to replace and maintain, requiring minimal downtime in case of a breakdown.Furthermore, the machine produces roofing tiles that are environmentally friendly and energy-efficient. The tiles are made of lightweight materials, reducing the load on the roof structure. They also have excellent heat insulation properties, making them ideal for use in hot and cold climates.In conclusion, the DX1000 Glazed Roof Tile Making Machine is a revolutionary machine that has transformed the color steel profile manufacturing industry. Its advanced technology and features have made it easier and faster to produce high-quality roofing tiles with ease. The machine is suitable for both small and large-scale production units and is an excellent investment for manufacturers looking to venture into the color steel roofing industry. If you are looking to invest in a machine that guarantees a high rate of success, consistency, durability, and efficiency, then the DX1000 Glazed Roof Tile Making Machine is an ideal choice.

Roll Forming Machine for Color Steel Production

Title: Advanced Color Steel Roll Forming Machine Revolutionizes the Steel Manufacturing IndustryIntroduction:With an ever-increasing demand for high-quality and sustainable construction materials, the global steel manufacturing industry has witnessed a significant technological advancement. The latest state-of-the-art Color Steel Roll Forming Machine has emerged as a game-changer, enabling efficient and precision-based production of color steel rolls.This groundbreaking technology, developed by a pioneering company committed to innovation and excellence in steel manufacturing, promises to revolutionize the industry. Designed to streamline the production process while reducing costs and enhancing product quality, this advanced roll forming machine is set to reshape the construction landscape.Streamlined Production Process:The Color Steel Roll Forming Machine automates and streamlines the manufacturing process for color steel rolls. It eliminates the need for manual labor, increasing both efficiency and productivity. With its fully automated operation, the machine can consistently produce high-quality, dimensionally accurate steel rolls at a significantly faster rate than traditional methods.Furthermore, this cutting-edge machine incorporates various advanced features such as automatic feeding, precision cutting, and accurate bending, ensuring a flawless end product. Additionally, it offers enhanced flexibility, allowing manufacturers to produce different profiles and sizes of color steel rolls as per customized requirements.Cost Efficiency and Reduced Waste:The Color Steel Roll Forming Machine is equipped with highly efficient energy-saving technologies. By optimizing power consumption and reducing material waste, it offers significant cost savings for manufacturers. The machine's ability to minimize production errors and material wastage ensures that each roll is utilized efficiently, thereby reducing overall expenses.Moreover, the advanced control system in the machine enables real-time monitoring and adjustment of production parameters. This not only enhances operational efficiency but also minimizes the need for manual intervention, further reducing labor costs.Environmental Sustainability:In line with the growing global focus on sustainability, the Color Steel Roll Forming Machine contributes to environmentally friendly manufacturing practices. Its energy-efficient design reduces carbon emissions and lowers the overall environmental footprint of the manufacturing process.Additionally, the machine's high precision and quality control mechanism ensure minimal material wastage, promoting sustainable resource management. By adopting this advanced technology, steel manufacturers can significantly reduce their impact on the environment and contribute to a greener future.Implications for the Steel Manufacturing Industry:The advent of the Color Steel Roll Forming Machine heralds a new era in the steel manufacturing industry. Its introduction is expected to bring about a multitude of benefits for manufacturers, contractors, and end-users alike.For manufacturers, the integration of this advanced technology allows for increased production capacity and reduced operational costs. The ability to produce a wide range of steel roll profiles opens up new market opportunities, catering to diverse customer demands.Contractors and construction firms benefit from the enhanced quality, precision, and efficiency of color steel rolls. These rolls, produced using the roll forming machine, exhibit superior durability, resistance to corrosion, and aesthetic appeal. The higher strength and reduced maintenance of color steel rolls significantly contribute to the longevity and sustainability of construction projects.Conclusion:The Color Steel Roll Forming Machine, developed by a leading company in steel manufacturing, represents a revolutionary leap forward in the industry. Its automated and efficient production process, coupled with cost-saving measures and environmental sustainability aspects, makes it the perfect solution for the evolving construction landscape.As more manufacturers integrate this advanced technology into their production lines, the steel manufacturing industry is poised to witness unparalleled growth and progress. The Color Steel Roll Forming Machine paves the way for a future where high-quality, sustainable, and economically viable construction materials become the norm, supporting the ever-growing infrastructure needs of our global society.

High-Quality Color Steel Sheet Roll Forming Machine for Efficient Production

Color Steel Sheet Roll Forming Machine Revolutionizes Manufacturing ProcessIn the highly competitive world of metal sheet manufacturing, companies are always on the lookout for innovative technology that can help them streamline their production processes and stay ahead of the competition. One such technology that has been making waves in the industry is the Color Steel Sheet Roll Forming Machine.This revolutionary machine has been developed by a leading company in the field of metal sheet manufacturing. Drawing on their years of expertise and industry knowledge, the company has designed a machine that is set to revolutionize the way metal sheets are produced.The Color Steel Sheet Roll Forming Machine is an advanced piece of equipment that is designed to roll-form steel into a variety of shapes and sizes. It is versatile and can be used to create a wide range of products, from roofing and wall cladding to decking and flooring. The machine is capable of producing high-quality, precision-engineered metal sheets that are not only durable and weather-resistant but also visually appealing.One of the key features of the Color Steel Sheet Roll Forming Machine is its efficiency. The machine is highly automated, which means that it requires minimal human intervention to operate. This not only speeds up the manufacturing process but also reduces the risk of errors and inconsistencies in the final product. The machine is also equipped with advanced control systems that allow for precise adjustments to be made, ensuring that the finished products meet the strictest quality standards.In addition to its efficiency, the Color Steel Sheet Roll Forming Machine is also highly versatile. It is capable of processing a wide range of materials, including galvanized steel, stainless steel, and aluminum. This makes it a valuable asset for manufacturers who work with different types of metals and need a machine that can adapt to their changing needs.Furthermore, the Color Steel Sheet Roll Forming Machine is designed with the environment in mind. It is equipped with energy-saving features that help to reduce its carbon footprint, making it a sustainable choice for manufacturers who are committed to reducing their environmental impact.The company behind the Color Steel Sheet Roll Forming Machine has a long-standing reputation for excellence in the field of metal sheet manufacturing. With years of experience and a deep understanding of the industry, they have been able to develop a machine that is not only technologically advanced but also practical and reliable.The company's team of engineers and designers have worked tirelessly to ensure that the Color Steel Sheet Roll Forming Machine meets the highest standards of quality and performance. They have taken into account the needs and feedback of their customers, as well as the latest advancements in technology, to create a machine that is truly cutting-edge.As a result of their efforts, the Color Steel Sheet Roll Forming Machine has already garnered attention from manufacturers around the world. Many companies are eager to adopt this new technology in order to enhance their production capabilities and gain a competitive edge in the market.In conclusion, the Color Steel Sheet Roll Forming Machine represents a significant advancement in the field of metal sheet manufacturing. With its efficiency, versatility, and environmental sustainability, it is set to transform the way metal sheets are produced and pave the way for a new era of innovation in the industry. As more manufacturers embrace this technology, we can expect to see a shift towards more cost-effective, high-quality, and sustainable metal sheet products in the market.