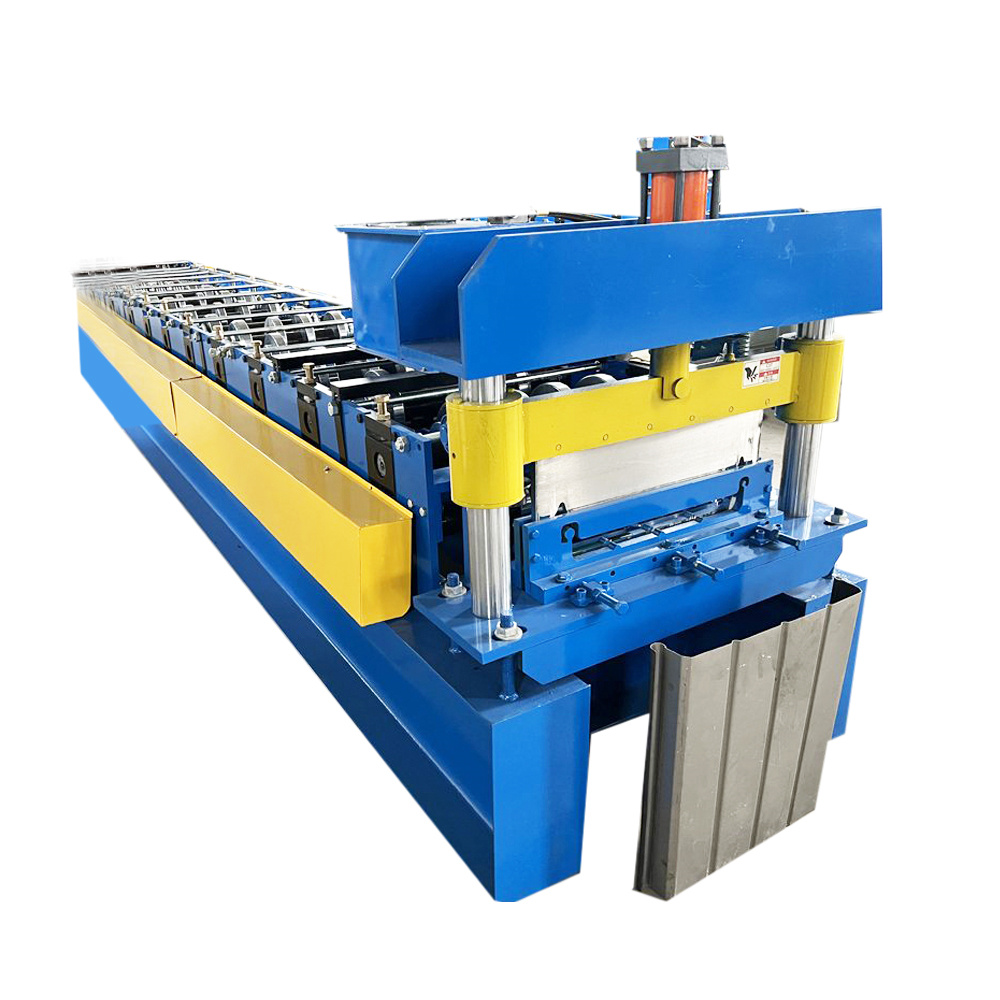

Steel Solar Mounting Structure Roll Forming Machine for Color Solar Panels

By:Admin

In today's ever-evolving world of technology and sustainable energy, the demand for solar power is rapidly increasing. As a result, the need for efficient and reliable solar mounting structure roll forming machines has never been greater. In response to this growing demand, {Company Name} is proud to announce the launch of their cutting-edge Color Steel Solar Mounting Structure Roll Forming Machine.

With a focus on innovation and quality, {Company Name} has been a leader in the roll forming machine industry for over 20 years. Their dedication to research and development, combined with state-of-the-art manufacturing facilities, has allowed them to produce some of the most advanced and reliable roll forming machines in the market. The Color Steel Solar Mounting Structure Roll Forming Machine is no exception, as it represents the latest advancement in solar mounting structure manufacturing technology.

One of the key features of the Color Steel Solar Mounting Structure Roll Forming Machine is its ability to produce high-quality, precision-engineered mounting structures for solar panels. The machine is equipped with advanced roll forming technology, which allows for the efficient and accurate shaping of color steel into the specific profiles required for solar panel mounting. This level of precision ensures that the mounting structures produced by the machine are not only durable and reliable but also perfectly designed to support solar panels in all types of environmental conditions.

Furthermore, the Color Steel Solar Mounting Structure Roll Forming Machine is designed for versatility and efficiency. It can accommodate a wide range of color steel materials, including galvanized steel, pre-painted steel, and aluminum, allowing for flexibility in manufacturing various types of solar mounting structures. In addition, the machine is equipped with automatic control systems, which enable seamless operation and precise adjustments to ensure consistent and high-quality output.

In line with {Company Name}'s commitment to sustainability, the Color Steel Solar Mounting Structure Roll Forming Machine is also designed to minimize material waste and energy consumption during the manufacturing process. By optimizing the roll forming process and utilizing advanced manufacturing techniques, the machine is able to maximize the utilization of raw materials and reduce energy consumption, ultimately contributing to a more sustainable and environmentally friendly manufacturing process.

The launch of the Color Steel Solar Mounting Structure Roll Forming Machine is a testament to {Company Name}'s dedication to meeting the evolving needs of the solar energy industry. With the growing demand for renewable energy sources, such as solar power, the need for reliable and efficient manufacturing equipment has never been greater. By introducing this cutting-edge roll forming machine, {Company Name} aims to provide solar panel manufacturers with the tools they need to meet the increasing demand for solar energy solutions while maintaining high standards of quality and sustainability.

As a global leader in roll forming machine manufacturing, {Company Name} is well-positioned to support the growing solar energy industry and contribute to the global transition towards sustainable energy sources. With a strong focus on innovation, quality, and sustainability, the company continues to be at the forefront of manufacturing technology, providing industry-leading solutions for solar panel mounting structure production.

In conclusion, the launch of the Color Steel Solar Mounting Structure Roll Forming Machine represents a significant milestone for {Company Name} and the solar energy industry as a whole. With its advanced technology, precision engineering, and commitment to sustainability, this machine is poised to play a crucial role in supporting the increasing demand for solar power solutions around the world. As the industry continues to evolve, {Company Name} remains dedicated to providing the most innovative and reliable manufacturing equipment for the solar energy industry, contributing to a more sustainable and environmentally friendly future.

Company News & Blog

Efficient and Durable Galvanized Steel Roll Forming Machine for Color Steel Production

Title: Advanced GP GI Color Steel Roll Forming Machine Revolutionizes the Steel Manufacturing IndustryIntroduction:In recent years, the steel construction industry has witnessed significant advancements due to continuous technological innovation and the introduction of state-of-the-art machinery. One such breakthrough is the revolutionary GP GI Color Steel Roll Forming Machine (brand name removed), developed by a cutting-edge company (brand name removed). This advanced technology has transformed the steel manufacturing process, providing numerous benefits and paving the way for a more efficient and sustainable construction industry.Efficiency and Versatility:The GP GI Color Steel Roll Forming Machine (brand name removed) boasts an array of innovative features that enable it to surpass conventional roll forming machines in terms of efficiency and versatility. Equipped with precision rolling blades, it can consistently produce high-quality, accurately shaped steel rolls with minimal wastage. Moreover, this machine offers customized settings for various steel thicknesses, allowing manufacturers to cater to a wide range of project requirements.Seamless Integration:One of the standout features of the GP GI Color Steel Roll Forming Machine (brand name removed) is its seamless integration with other key components of the steel manufacturing process. This harmonious interplay ensures a comprehensive and streamlined production line, minimizing downtime and maximizing overall productivity. Integrated quality control mechanisms further enhance the accuracy and reliability of the final output, ensuring consistent adherence to industry standards.Enhanced Safety Measures:Safety is a paramount concern in any manufacturing environment. The GP GI Color Steel Roll Forming Machine (brand name removed) addresses this crucial aspect by implementing a range of advanced safety features. Machine operators are provided with comprehensive training on proper handling and safety protocols, reducing the risk of accidents. Additionally, the machine incorporates built-in sensors and alarms to detect potential malfunctions or anomalies, enabling prompt intervention and preventing mishaps.Sustainable Manufacturing:Emphasizing the importance of sustainability, the developers of the GP GI Color Steel Roll Forming Machine (brand name removed) have integrated eco-friendly features to decrease the machine's environmental impact. By optimizing energy usage and reducing material waste, this machine ensures a more sustainable and responsible manufacturing process. Moreover, the use of high-quality steel results in a longer lifespan for the finished products, minimizing the need for frequent replacements and reducing overall carbon footprint.Increased Productivity and Cost Efficiency:The GP GI Color Steel Roll Forming Machine (brand name removed) greatly enhances the productivity of steel manufacturers, enabling faster cycle times and increased product output. The precision and speed at which this machine operates considerably reduce the time required for roll forming, enabling manufacturers to meet tight project deadlines. Furthermore, the minimized material wastage and energy optimization result in significant cost savings and enhanced profitability for steel manufacturing companies.Market Advantages:The incorporation of the GP GI Color Steel Roll Forming Machine (brand name removed) by steel manufacturers provides a competitive edge in the market. The superior quality and precision of the formed steel rolls lead to customer satisfaction, thereby enhancing long-term business relationships. Moreover, the ability to customize the machine according to specific project demands allows manufacturers to cater to a broader clientele, expanding their market reach and improving overall business prospects.Conclusion:The GP GI Color Steel Roll Forming Machine (brand name removed) has brought a transformational shift to the steel manufacturing industry, greatly improving efficiency, safety, and sustainability while reducing production costs. This innovative technology has set a new standard in roll forming machines, enabling manufacturers to meet the ever-increasing demands of the construction sector. With its advanced features and benefits, this machine is undeniably a game-changer in the steel manufacturing landscape, promoting progress and innovation while simultaneously caring for the environment.

Revolutionary Technology Takes Color Steel Profile Manufacturing to the Next Level

Color Steel Profile Manufacturing Machine: Revolutionizing the Construction IndustryIn an era where technological innovations continue to transform various industries, the construction sector is not far behind. One such groundbreaking development is the introduction of the Color Steel Profile Manufacturing Machine, a game-changer that has revolutionized the steel manufacturing process. This cutting-edge equipment has not only improved efficiency but has also enhanced product quality, making it a preferred choice for numerous construction projects worldwide.The Color Steel Profile Manufacturing Machine, developed by an industry-leading company specializing in steel manufacturing equipment, has gained tremendous popularity within a short span of time. Founded in [year of establishment], the company has quickly emerged as a frontrunner in this niche market due to their relentless commitment to research and development, customer-centric approach, and dedication to delivering innovative solutions.The color steel profile manufacturing process begins with the raw materials. The machine can work with a range of materials, including galvanized steel, stainless steel, and aluminum, providing flexibility to cater to diverse project requirements. The company's proficiency in material selection and customization allows them to develop profiles that are not only aesthetically pleasing but also durable and resilient, ensuring longevity and resistance to external factors such as corrosion and weather fluctuations.One of the key advantages of the Color Steel Profile Manufacturing Machine is its advanced automation capabilities. This state-of-the-art equipment is equipped with sophisticated sensors, precision controllers, and cutting-edge software, enabling it to operate with minimal human intervention. This reduces the risk of errors, optimizes production time, and enhances overall efficiency. The machine's automated processes also contribute to cost reduction, as it eliminates the need for extensive manual labor.In addition to its automation capabilities, the Color Steel Profile Manufacturing Machine boasts remarkable precision and accuracy in profile creation. The company's team of experienced engineers and technicians ensures that each profile is meticulously designed and manufactured to meet the highest industry standards. The machine's advanced technology enables it to produce profiles with consistent dimensions, sharp edges, and smooth finishes, guaranteeing a flawless final product.Furthermore, the Color Steel Profile Manufacturing Machine prioritizes environmental sustainability. The company's commitment to green manufacturing practices is reflected in the machine's energy-efficient operations. By employing energy-saving technologies and optimizing resource utilization, the machine minimizes its carbon footprint, making it an eco-friendly choice for environmentally conscious construction projects.The versatility of the Color Steel Profile Manufacturing Machine is yet another notable feature. With the ability to produce a wide range of profiles, such as roofing sheets, wall panels, floor decking, and ceiling systems, this equipment caters to the diverse needs of the construction industry. Its adaptability allows architects and builders to bring their creative visions to life, facilitating the realization of unique and striking architectural designs.As the construction industry continues to evolve, the demand for efficient and high-quality steel manufacturing equipment is on the rise. The Color Steel Profile Manufacturing Machine stands at the forefront of this technological leap, offering a myriad of benefits to various stakeholders, including manufacturers, contractors, and end-users. Its advanced features, precision engineering, eco-friendly operations, and versatility make it an indispensable tool for the modern construction industry.In conclusion, the Color Steel Profile Manufacturing Machine is a remarkable innovation that has transformed the steel manufacturing process. With its advanced automation, precision engineering, environmental sustainability, and versatility, this equipment has become an indispensable asset for construction projects worldwide. As the industry evolves, this game-changing machine continues to redefine the future of steel profile manufacturing, offering endless possibilities for architects, builders, and construction companies alike.

Top Color Steel Sheet Roll Forming Machines: Industry-leading Solutions for Efficient Sheet Roll Forming Processes Revealed!

Title: Innovative Color Steel Sheet Roll Forming Machine Revolutionizes the IndustryIntroduction:In today's fast-paced world, the demand for efficient and high-quality manufacturing processes is pivotal for industries across the globe. Companies are constantly searching for innovative solutions that can optimize production and ensure superior product quality. One such groundbreaking development is the Color Steel Sheet Roll Forming Machine, a cutting-edge technology designed to transform the manufacturing landscape in the steel industry.Body:1. The Evolution of Color Steel Sheet Roll Forming:Since its inception, the roll forming process has gone through significant advancements, exhibiting its versatility in various applications. Initially, limited to producing simple shapes, roll forming has evolved into a highly flexible and automated method capable of manufacturing complex profiles, such as color steel sheets.2. Enhanced Efficiency and Productivity:The newly unveiled Color Steel Sheet Roll Forming Machine brings unmatched efficiency and productivity to the table. With its automated capabilities and precision engineering, this machine significantly reduces human error and increases production output. The machine incorporates automated cutting and bending functions, ensuring consistent results and high-quality color steel sheets.3. Exceptional Product Quality:By combining top industry materials with state-of-the-art manufacturing processes, this roll forming machine consistently produces color steel sheets of exceptional quality. The machine's superior precision guarantees perfect dimensions and consistency in profile, resulting in uniform panels that meet and exceed industry standards.4. Customization and Design Flexibility:The Color Steel Sheet Roll Forming Machine offers unparalleled potential for customization and design flexibility. It can produce a wide array of shapes and profiles with ease, enabling manufacturers to cater to diverse market demands. From corrugated sheets to trapezoidal panels, the machine empowers companies to meet unique design requirements, ultimately enhancing their competitiveness.5. Cost-effectiveness and Sustainability:In addition to its impressive performance, the color steel sheet roll forming machine provides cost-effective manufacturing solutions. By optimizing material usage and minimizing waste, it helps reduce production costs significantly. Moreover, the machine's efficient use of resources results in a more sustainable manufacturing process, reducing environmental impact.6. Integration of Advanced Technology:The Color Steel Sheet Roll Forming Machine integrates advanced technologies with intelligent control systems, ensuring seamless operation throughout the production process. Real-time monitoring and automated adjustments guarantee high precision and improve overall productivity. Additionally, the machine offers seamless integration with other production line equipment, further streamlining the manufacturing process.7. Expanding Market Opportunities:The introduction of the Color Steel Sheet Roll Forming Machine creates immense market opportunities for both existing manufacturers and new entrants within the steel industry. The machine's versatility and ability to adapt to different applications provide manufacturers with a competitive advantage, enabling them to capture a wider customer base.Conclusion:The introduction of the Color Steel Sheet Roll Forming Machine revolutionizes the steel industry, combining efficient production capabilities with superior product quality. With its automated functions, design flexibility, cost-effectiveness, and sustainability, this innovative machine proves to be a game-changer in the manufacturing sector. As companies embrace this technology, they empower themselves to stay ahead in a rapidly evolving market, ultimately shaping a promising future for the steel industry.

High-Quality Color Steel Sheet Roll Forming Machine for Sale - Get Yours Today!

Color Steel Sheet Roll Forming Machine Revolutionizing the Construction IndustryInnovation is the driving force behind the construction industry's evolution. From new materials and techniques to advanced machinery, companies are constantly looking for ways to improve efficiency, decrease costs, and enhance the quality of their products. The Color Steel Sheet Roll Forming Machine is one such innovation that is revolutionizing the construction industry.With the demand for high-quality building materials on the rise, there is an increasing need for advanced machinery that can produce these materials quickly and efficiently. This is where the Color Steel Sheet Roll Forming Machine comes in. Developed by a leading manufacturer in the field, this state-of-the-art machine is designed to produce color-coated steel sheets with precision and speed.The Color Steel Sheet Roll Forming Machine is equipped with advanced technology that allows for seamless production of steel sheets in various colors, thicknesses, and sizes. This level of customization is invaluable to builders and contractors who require specific materials for their projects. Furthermore, the machine's high production capacity ensures that large quantities of steel sheets can be produced in a short amount of time, meeting the demands of even the most sizable construction projects.One of the key features of the Color Steel Sheet Roll Forming Machine is its user-friendly interface. The machine is designed to be easy to operate, requiring minimal training for workers to become proficient in its use. This saves both time and money for companies, as they can quickly integrate the machine into their production process without significant downtime or additional training costs.In addition to its efficiency and ease of use, the Color Steel Sheet Roll Forming Machine is also designed with durability and reliability in mind. Constructed with high-quality materials and components, the machine is built to withstand the rigors of continuous use in a demanding industrial environment. This ensures that companies can rely on the machine to deliver consistent and high-quality results over an extended period.The introduction of the Color Steel Sheet Roll Forming Machine is a game-changer for the construction industry. Its ability to produce custom color-coated steel sheets at a rapid pace is a significant advancement in the field. With this machine, builders and contractors can access high-quality building materials quickly and efficiently, enabling them to meet tight project deadlines and deliver superior results.The company behind the Color Steel Sheet Roll Forming Machine is a leading manufacturer of industrial machinery. With a strong focus on innovation and continuous improvement, the company has established itself as a trusted name in the industry. Its commitment to delivering cutting-edge solutions that meet the evolving needs of the construction sector has earned it a reputation for excellence.In conclusion, the Color Steel Sheet Roll Forming Machine is a groundbreaking innovation that is transforming the construction industry. Its advanced technology, high production capacity, user-friendly interface, and durability make it an invaluable asset for companies seeking to streamline their production process and deliver superior building materials. As the demand for high-quality construction materials continues to grow, the Color Steel Sheet Roll Forming Machine is poised to play a vital role in meeting this need and driving the industry forward.

Ultimate Guide to Color Steel Roll Forming Machine: Everything You Need to Know

Color Steel Roll Forming Machine is one of the crucial equipment used in the production of color coated steel sheets and panels. It is designed to efficiently and accurately bend and shape the steel, resulting in high-quality finished products. With the growing demand for color steel products in various industries such as construction, automotive, and furniture, the need for reliable and efficient roll forming machines has become essential.{Company name}, a leading manufacturer of roll forming machines, has been providing innovative and high-performance solutions for the metal forming industry for over a decade. Their expertise in designing and manufacturing roll forming equipment has made them a trusted partner for businesses looking to enhance their production capabilities.The Color Steel Roll Forming Machine offered by {Company name} is equipped with advanced features that ensure precision, speed, and durability. The machine is capable of processing different types of steel, including galvanized steel, pre-painted steel, and aluminum. This versatility allows manufacturers to produce a wide range of color steel products to meet the diverse needs of their customers.One of the key highlights of {Company name}'s Color Steel Roll Forming Machine is its user-friendly interface and automation capabilities. The machine is designed to be easy to operate, reducing the need for extensive training and minimizing the potential for errors. Additionally, the automation features enable seamless integration with other production processes, optimizing overall efficiency and productivity.Furthermore, the roll forming machine is built with robust materials and components, ensuring long-term reliability and minimal downtime. This commitment to quality and durability reflects {Company name}'s dedication to delivering equipment that meets the rigorous demands of modern manufacturing environments.In addition to the machine itself, {Company name} offers comprehensive support services to assist customers in maximizing the performance of their Color Steel Roll Forming Machine. This includes installation, training, maintenance, and technical assistance, providing a complete solution for businesses looking to invest in a reliable roll forming system.When asked about the significance of the Color Steel Roll Forming Machine for their customers, {Company name}'s spokesperson highlighted the impact on production efficiency and product quality. "Our roll forming machines are designed to streamline the production process and deliver consistent, high-quality results. By investing in our equipment, businesses can significantly improve their manufacturing capabilities and stay ahead in a highly competitive market."The growing popularity of color steel products in various industries, coupled with the increasing demand for efficient and reliable production equipment, underscores the importance of investing in a high-quality roll forming machine. {Company name} recognizes the evolving needs of their customers and continues to innovate their product offerings to support the growth and success of businesses in the metal forming industry.As a trusted partner for roll forming solutions, {Company name} remains committed to delivering cutting-edge equipment, unparalleled support, and ongoing value for their customers. With the Color Steel Roll Forming Machine, businesses can enhance their production capabilities, expand their product offerings, and ultimately achieve greater success in today's competitive marketplace.

Efficient and Durable Roofing Roll Forming Machine for Color Steel Roofs

Title: Cutting-Edge Color Steel Roofing Roll Forming Machine Revolutionizes Roofing IndustryIntroduction:In an era of constant technological advancements, industries are continually seeking innovative solutions to improve their manufacturing processes. The roofing industry is no exception, with the introduction of the cutting-edge Color Steel Roofing Roll Forming Machine paving the way for significant improvements in speed, efficiency, and quality in roof production. Driven by its commitment to engineering excellence, [Company Name], a leading manufacturer of roofing systems, launched this state-of-the-art machine, which is set to revolutionize the roofing industry.Body:1. Overview of the Color Steel Roofing Roll Forming Machine:The Color Steel Roofing Roll Forming Machine represents the culmination of years of research and development by [Company Name]. This advanced machine is engineered to streamline the roofing production process by forming and shaping steel sheets into precise profiles in a highly efficient and automated manner.2. Unprecedented Speed and Efficiency:The Color Steel Roofing Roll Forming Machine boasts unparalleled speed and efficiency, drastically reducing production time and costs. With its advanced features and automated functionality, the machine is capable of producing high-quality, uniform roofing sheets at a rate of [Specify Rate] meters per minute. This incredible speed allows manufacturers to meet tight deadlines, increase productivity, and subsequently enhance their overall profitability.3. Superior Precision and Quality:The stringent quality control standards of the Color Steel Roofing Roll Forming Machine ensure consistent precision throughout the manufacturing process. The machine's automated processes guarantee accurate sheet profiling with minimal wastage. By maintaining precise dimensions and shape, the machine eliminates human errors and ensures high-quality roofing products that conform to industry standards. Additionally, the machine's cutting-edge technology ensures optimal sheet flatness, further enhancing the durability and reliability of the produced roofing materials.4. Versatility and Customization Capabilities:The Color Steel Roofing Roll Forming Machine caters to a wide range of roofing needs, offering manufacturers unparalleled versatility and customization options. With the ability to produce various profiles, including corrugated or trapezoidal sheets, the machine allows manufacturers to meet diverse customer preferences and project requirements. This versatility positions manufacturers for increased success, as they can readily adapt to changing market demands.5. Enhanced Safety and Easy Operation:[Company Name]'s commitment to safety is evident in the design of the Color Steel Roofing Roll Forming Machine. Equipped with advanced safety features, such as emergency stop buttons and protective guards, the machine ensures the well-being of operators and minimizes the risk of accidents. Furthermore, the machine's intuitive interface and user-friendly controls make it easily operable, eliminating the need for extensive training and reducing operator errors.6. Environmental Sustainability:Incorporating sustainable practices into manufacturing processes has become a global imperative, and the Color Steel Roofing Roll Forming Machine holds true to this commitment. By minimizing energy consumption through optimized engine performance and innovative design, this machine significantly reduces carbon emissions. Furthermore, the machine's efficient use of materials, along with its ability to recycle and reuse excess materials, further reduces the environmental footprint of the roofing industry.Conclusion:With the introduction of the Color Steel Roofing Roll Forming Machine, [Company Name] has reaffirmed its position as an industry leader committed to driving innovation in the roofing sector. The machine's unprecedented speed, efficiency, and precision are set to revolutionize the roofing industry, enabling manufacturers to meet increasing customer demands while maintaining superior quality. As the market becomes increasingly competitive, investing in advanced technologies such as this machine will be crucial for companies seeking to stay ahead and embrace a sustainable future.

Ultimate Guide to Color Steel Roll Forming Machines: Essential Insights and Tips

Title: Revolutionary Color Steel Roll Forming Machine Revolutionizes Manufacturing Industry Introduction: In today's rapidly evolving manufacturing industry, a new and innovative solution has emerged in the form of a state-of-the-art Color Steel Roll Forming Machine. Designed with cutting-edge technology and engineered for efficiency, this groundbreaking machine has the potential to revolutionize the way steel is processed and transformed into various construction materials. With its streamlined operation and remarkable output capabilities, the Color Steel Roll Forming Machine (brand name to be removed) promises to reshape the industry landscape, setting new standards for productivity and precision.Innovative Features:The Color Steel Roll Forming Machine incorporates a range of innovative features that elevate its performance and efficiency. One of its key advantages is its ability to process steel sheets seamlessly, forming them into precise shapes with exceptional precision. The machine's advanced computer-controlled system ensures consistent output, reducing the margin of errors, and improving the overall product quality.Additionally, the Color Steel Roll Forming Machine is equipped with a highly efficient material feeding system, enabling a continuous flow of steel sheets into the machine. This eliminates unnecessary downtime and maximizes productivity, providing a significant advantage to manufacturers seeking seamless, uninterrupted production.Furthermore, the machine's automatic cutting system ensures accurate and clean cuts, eliminating the need for additional post-processing. This not only saves time but also reduces material wastage, making it an environmentally conscious choice for manufacturers worldwide.Unmatched Versatility:The Color Steel Roll Forming Machine boasts unparalleled versatility, capable of producing an extensive range of architectural steel products. From roofing panels and wall claddings to steel trusses and structural profiles, this machine accommodates diverse market demands with ease. Manufacturers can swiftly switch between product specifications, effortlessly adapting to evolving customer needs, and market trends.Energy Efficiency:As the manufacturing industry continues to prioritize sustainable practices, the Color Steel Roll Forming Machine stands out for its eco-friendly design. By utilizing advanced energy-saving technologies, it minimizes power consumption without compromising production efficiency. With reduced energy costs and carbon footprints, manufacturers using this machine contribute towards a greener future for the industry.Automation and Ease of Use:Designed with user-friendliness in mind, the Color Steel Roll Forming Machine empowers both experienced professionals and newcomers in the manufacturing industry. With its intuitive interface and integrated automation capabilities, operators can easily program and adjust settings, ensuring optimal performance and quick setup times. This minimizes the need for highly skilled labor and reduces training costs, making it an attractive investment for manufacturers of all scales.Market Impact:The introduction of the Color Steel Roll Forming Machine is expected to leave a lasting impact on the manufacturing industry. Its ability to streamline production processes, improve product consistency, and increase overall efficiency redefines the standards for steel processing. With reduced operational costs and enhanced product quality, manufacturers can gain a competitive edge in the market, meet rising customer expectations, and expand their market share.Conclusion:The Color Steel Roll Forming Machine, with its advanced features, unrivaled versatility, and eco-conscious design, represents a major breakthrough in the manufacturing industry. By utilizing innovative technologies and automation, it optimizes production processes and offers significant benefits to businesses across the sector. As manufacturers embrace this groundbreaking machine, they will pave the way for a more sustainable and efficient future, revolutionizing the industry as a whole.

Efficient and Durable Metal Glazed Tile Roll Forming Machine Unveiled in Latest News

(Color Steel Metal Glazed Tile Roll Forming Machine)Over the years, the construction industry has witnessed significant advancements in technology aimed at improving efficiency and performance. One such innovation is the Color Steel Metal Glazed Tile Roll Forming Machine, which is revolutionizing the process of producing high-quality metal glazed tiles. This state-of-the-art machinery offers increased precision, speed, and flexibility, making it an invaluable asset for construction companies globally.The Color Steel Metal Glazed Tile Roll Forming Machine (name removed) is engineered to meet the growing demands of the construction industry, providing a seamless solution for manufacturing metal glazed tiles. It incorporates advanced technology that allows for precise control over the entire production process, resulting in consistent and precise tile profiles. With its high-speed capabilities, this machine can produce a large volume of tiles in a short period, catering to even the most demanding project timelines.One of the most notable features of this cutting-edge machine is its flexibility. The Color Steel Metal Glazed Tile Roll Forming Machine accommodates various tile sizes, allowing for versatility in design and construction. Whether it's a residential, commercial, or industrial project, this machinery can adapt to meet specific requirements, enabling architects and designers to unleash their creativity while ensuring structural integrity.In addition to its flexibility, the Color Steel Metal Glazed Tile Roll Forming Machine excels in its durability and longevity. Constructed with high-quality materials and components, this machine can withstand heavy production loads without compromising on performance. Its robust build guarantees consistent and reliable results, minimizing downtime and maximizing productivity for construction companies.Furthermore, this advanced machinery boasts user-friendly features that enhance efficiency and ease of use. Equipped with intuitive controls and interfaces, operators can easily navigate and program the machine to achieve desired tile profiles and dimensions. The Color Steel Metal Glazed Tile Roll Forming Machine also incorporates safety features, ensuring a secure working environment for the operators.As construction companies strive to meet increasing market demands, the Color Steel Metal Glazed Tile Roll Forming Machine serves as a valuable asset in streamlining production processes. Its efficient and precise nature allows for faster completion of projects, reducing overall costs and enhancing customer satisfaction. With this machinery, construction companies can maintain a competitive edge in the industry by delivering high-quality metal glazed tiles efficiently and effectively.(company introduction)In line with the ever-evolving needs of the construction industry, our company has emerged as a leader in providing innovative solutions and technologies. With a commitment to excellence and a drive for continuous improvement, we have established ourselves as a trusted partner for construction companies worldwide.Our extensive experience and expertise in the construction sector have enabled us to identify key challenges faced by our clientele. In response, we have invested in research and development to design and manufacture cutting-edge machinery that meets and surpasses industry expectations.Driven by a customer-centric approach, we prioritize understanding the unique requirements of each construction project. By collaborating closely with architects, designers, and construction professionals, we develop solutions that optimize performance, efficiency, and aesthetics.Our commitment to quality is unwavering, reflected in every component and feature of our machinery. Partnering with renowned experts and utilizing state-of-the-art manufacturing processes, we ensure that our products adhere to the highest standards of excellence and durability.Additionally, we recognize the importance of user experience and safety. Our machinery is designed with user-friendly interfaces and intuitive controls, empowering operators to maximize productivity while minimizing the risk of accidents. The safety of our operators and customers is paramount, and we continuously strive to enhance the safety features of our machines.As we look towards the future, we remain dedicated to pushing the boundaries of innovation in the construction industry. With a strong focus on research and development, we aim to deliver groundbreaking solutions that continue to redefine the way we build. Together with our valued partners, we forge ahead, shaping the future of construction one project at a time.

High-Quality Three-Layers Roof Sheet Color Corrugated Roof Tile Roll Forming Machine from China

Title: The Evolution of Three Layers Color Steel Roll Forming Machine: Unmatched Precision and QualityIntroduction:In today's dynamic construction industry, high-quality roofing materials have become an essential aspect of building durability and aesthetics. Among the diverse range of roofing solutions, three layers color steel sheet corrugated roof tiles have emerged as a preferred choice for their durability, versatility, and aesthetic appeal. Playing a pivotal role in the manufacturing process, advanced automatic three layers roof sheet color corrugated roof tile roll forming machines from China have revolutionized the production of these superior roofing materials.Enhanced Precision and Superior Quality:The automatic three layers roof sheet color corrugated roof tile roll forming machine represents the pinnacle of innovative engineering and craftsmanship. Engineered with cutting-edge technology, these machines are designed to produce roof sheets with utmost precision and superior quality. They incorporate a three-layer manufacturing process, allowing for exceptional durability, weather resistance, and insulation properties.The Layers Explained:The first layer of the three layers color steel roll forming machine is the protective layer, consisting of a thick coating designed to provide exceptional resistance against corrosion, UV radiation, and adverse weather conditions. This protective layer ensures that the roof sheets maintain their aesthetic appeal and structural integrity for an extended period.Underneath the protective layer lies the base material layer, typically comprising galvanized steel. This layer assures rigidity and strength to the roof sheets, making them capable of withstanding heavy snow loads, hailstorms, and various external forces.The final layer is the surface layer, where the color coating is applied. This layer imparts a visually appealing finish to the roof sheets, enhancing the overall aesthetics of the buildings. The color coating is available in a multitude of shades, catering to the diverse architectural preferences and styles.Advanced Roll Forming Machineries:China's leading manufacturers have perfected the art of designing and producing high-quality automatic three layers roof sheet color corrugated roof tile roll forming machines. These machines are equipped with state-of-the-art features and high-precision components.The roll forming process begins with feeding the base material layer into the machine. The sheet is then accurately shaped into the desired corrugated profile via a series of precision rollers. The machine's cutting-edge control system ensures uniformity of the corrugated pattern, leaving no room for imperfections. This precise method guarantees that every sheet produced is of the highest quality and meets the strictest industry standards.Quality Control and Reliability:To maintain the consistency and reliability of the production process, strict quality control measures are implemented throughout every stage of manufacturing. From raw material inspection to final product testing, these machines undergo rigorous quality checks at every step.By adhering to strict quality control guidelines, manufacturers ensure that the automatic three layers roof sheet color corrugated roof tile roll forming machines are capable of producing roof sheets that offer unparalleled longevity, durability, and resistance against environmental elements. This commitment to quality has earned Chinese manufacturers a reputation as leaders in the industry, with their machines being sought after globally.Conclusion:The automatic three layers roof sheet color corrugated roof tile roll forming machine has revolutionized the roofing industry by offering high precision, durability, and superior quality. Its three-layer manufacturing process, combined with advanced technology, ensures that the roof sheets produced are not only visually appealing but also capable of withstanding the most demanding weather conditions.China's leading manufacturers have consistently delivered high-quality automatic roll forming machines, earning their place as trusted providers of top-notch roof tile roll forming machinery. With their commitment to quality, reliability, and innovation, these machines continue to play a vital role in building sustainable and aesthetically pleasing structures worldwide.

Revolutionary Fully Automatic Color Steel Roll Forming Machine Unveiled in Latest News

Fully Automatic Roll Forming Machine Revolutionizes Color Steel ProductionWith the constant innovation and development in the manufacturing sector, a new breakthrough has been achieved with the introduction of the fully automatic roll forming machine for color steel. This state-of-the-art technology is set to revolutionize the production process and enhance the efficiency and quality of color steel production.Color steel, also known as pre-painted steel, has gained immense popularity in various industries due to its versatility, durability, and aesthetic appeal. It is widely used in the construction of roofs, walls, and other structural components. Traditionally, color steel production involved manual labor that required considerable time and effort. However, with the advent of fully automatic roll forming machines, the production process has become significantly faster, more precise, and cost-effective.The innovative features of this advanced machine eliminate the need for manual intervention, resulting in increased productivity and reduced error rates. The roll forming machine operates seamlessly, starting from the loading of steel coils to the final product, with minimal human involvement. The machine incorporates cutting-edge technology that ensures precise shaping, bending, and cutting of the steel sheets, resulting in perfectly formed color steel components.One of the key advantages of the fully automatic roll forming machine is its ability to handle a wide range of color steel materials, including galvanized steel, galvalume steel, and various coated steel sheets. This flexibility allows manufacturers to cater to the diverse needs of their customers and offer a wide range of color options. The machine can effortlessly produce color steel profiles of various shapes and sizes, meeting the requirements of different construction projects.Furthermore, the fully automatic roll forming machine is equipped with an intelligent control system that enables smooth and efficient operation. The control system allows operators to set precise parameters, monitor the production process in real-time, and make adjustments as needed. This ensures consistent quality and minimizes material wastage, further optimizing the production efficiency.In addition to its operational efficiency, the fully automatic roll forming machine also prioritizes worker safety. With its advanced safety features and protective measures, the machine significantly reduces the risk of accidents and injuries during the production process. This creates a safer working environment and improves overall worker morale and satisfaction.As a leader in the manufacture and supply of roll forming machines, [Company Name] has introduced this cutting-edge technology to the market. The company's commitment to research and development has enabled them to design and produce machinery that meets the evolving needs of the industry. With extensive experience and expertise, [Company Name] has become a trusted name in the roll forming machine industry.The introduction of the fully automatic roll forming machine by [Company Name] signifies a leap forward in color steel production. This technology revolutionizes the manufacturing process, bringing numerous benefits to manufacturers, construction companies, and end-users alike. The increased speed, precision, and quality of color steel production will contribute to the advancement of the construction industry and fuel economic growth.In conclusion, the fully automatic roll forming machine has emerged as a game-changer in the color steel production industry. Its advanced features, efficient operation, and focus on worker safety make it an invaluable asset for manufacturers. With [Company Name] at the forefront of this technology, the future of color steel production is brighter than ever.