Discover the Latest Innovations in Steel Roll Forming Machines

By:Admin

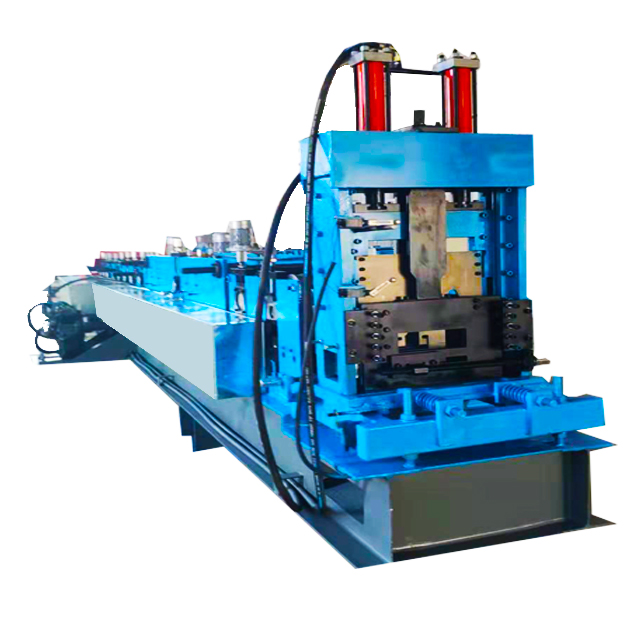

The manufacturing industry, particularly the steel industry, has been a significant source of growth and prosperity for the economy at large. As the world continues to develop and progress, demands for high-quality steel products continue to rise accordingly. To meet these demands while remaining competitive, businesses, and manufacturers must strive to employ state-of-the-art machinery and equipment. In this vein, the Color Steel Roll Forming Machine, developed by the team at [company name], has revolutionized the industry.

The Color Steel Roll Forming Machine has been designed for the efficient and precise production of high-quality steel products. This advanced piece of equipment uses a cold-roll forming process to transform flat sheets of metal into complex shapes and designs with ease. The finished products are durable, and aesthetically pleasing and can be used in various construction and building applications, including roofing, wall and ceiling cladding, and insulation.

This innovative industrial machine boasts a range of features that set it apart from traditional roll-forming machines. The machine's advanced software and hardware systems ensure a high degree of accuracy and precision in the forming process. It is equipped with state-of-the-art controls that allow operators to program the machine to produce a wide range of shapes and designs, without requiring manual adjustments for each operation. Further, it has a continuous production process, which eliminates delays, reduces waste, and increases productivity.

One significant benefit of using the Color Steel Roll Forming Machine is its versatility. The machine can work with a range of metals, including aluminum, copper, and stainless steel. It can form steel sheets into various profiles, including corrugated, trapezoidal, and tile shapes, making it a versatile and cost-effective solution for businesses that require custom-made steel products.

[Company name] is a well-known player in the steel manufacturing industry, providing a broad range of products and services to customers all over the world. Their dedication to producing high-quality products is exemplified in their use of the Color Steel Roll Forming Machine, which has helped them maintain a competitive edge over their rivals.

Their machines have been manufactured with the most advanced technology and materials, ensuring precise and reliable performance in demanding manufacturing environments. [Company name] understands that the investment made for such an innovative machine is significant, and in response, they provide ongoing support services to their clients. Their expertise in repair and maintenance guarantees that their customers' machines won't remain idle should any breakdowns occur.

The Color Steel Roll Forming Machine has proved to be a game-changer in the steel manufacturing industry. It has reduced the time, resources, and labor required for producing custom products, thereby increasing profitability and efficiency for manufacturers. Moreover, it has enabled manufacturers to meet the ever-increasing demands of customers for high-quality steel products. Notably, the most significant benefit of using this machine is the consistently high-quality products it produces, which meet and exceed industry standards.

In conclusion, the Color Steel Roll Forming Machine is an indispensable tool for modern steel manufacturers. Its unique combination of efficiency and precision has revolutionized the steel industry, resulting in higher quality products, increased productivity, and reduced costs. If your business is looking for an innovative solution to steel fabrication, you need to consider incorporating the Color Steel Roll Forming Machine into your operations. With [company name] as your partner, this machine provides an unbeatable solution for all your steel fabrication needs.

Company News & Blog

Efficient and Durable Metal Glazed Tile Roll Forming Machine Unveiled in Latest News

(Color Steel Metal Glazed Tile Roll Forming Machine)Over the years, the construction industry has witnessed significant advancements in technology aimed at improving efficiency and performance. One such innovation is the Color Steel Metal Glazed Tile Roll Forming Machine, which is revolutionizing the process of producing high-quality metal glazed tiles. This state-of-the-art machinery offers increased precision, speed, and flexibility, making it an invaluable asset for construction companies globally.The Color Steel Metal Glazed Tile Roll Forming Machine (name removed) is engineered to meet the growing demands of the construction industry, providing a seamless solution for manufacturing metal glazed tiles. It incorporates advanced technology that allows for precise control over the entire production process, resulting in consistent and precise tile profiles. With its high-speed capabilities, this machine can produce a large volume of tiles in a short period, catering to even the most demanding project timelines.One of the most notable features of this cutting-edge machine is its flexibility. The Color Steel Metal Glazed Tile Roll Forming Machine accommodates various tile sizes, allowing for versatility in design and construction. Whether it's a residential, commercial, or industrial project, this machinery can adapt to meet specific requirements, enabling architects and designers to unleash their creativity while ensuring structural integrity.In addition to its flexibility, the Color Steel Metal Glazed Tile Roll Forming Machine excels in its durability and longevity. Constructed with high-quality materials and components, this machine can withstand heavy production loads without compromising on performance. Its robust build guarantees consistent and reliable results, minimizing downtime and maximizing productivity for construction companies.Furthermore, this advanced machinery boasts user-friendly features that enhance efficiency and ease of use. Equipped with intuitive controls and interfaces, operators can easily navigate and program the machine to achieve desired tile profiles and dimensions. The Color Steel Metal Glazed Tile Roll Forming Machine also incorporates safety features, ensuring a secure working environment for the operators.As construction companies strive to meet increasing market demands, the Color Steel Metal Glazed Tile Roll Forming Machine serves as a valuable asset in streamlining production processes. Its efficient and precise nature allows for faster completion of projects, reducing overall costs and enhancing customer satisfaction. With this machinery, construction companies can maintain a competitive edge in the industry by delivering high-quality metal glazed tiles efficiently and effectively.(company introduction)In line with the ever-evolving needs of the construction industry, our company has emerged as a leader in providing innovative solutions and technologies. With a commitment to excellence and a drive for continuous improvement, we have established ourselves as a trusted partner for construction companies worldwide.Our extensive experience and expertise in the construction sector have enabled us to identify key challenges faced by our clientele. In response, we have invested in research and development to design and manufacture cutting-edge machinery that meets and surpasses industry expectations.Driven by a customer-centric approach, we prioritize understanding the unique requirements of each construction project. By collaborating closely with architects, designers, and construction professionals, we develop solutions that optimize performance, efficiency, and aesthetics.Our commitment to quality is unwavering, reflected in every component and feature of our machinery. Partnering with renowned experts and utilizing state-of-the-art manufacturing processes, we ensure that our products adhere to the highest standards of excellence and durability.Additionally, we recognize the importance of user experience and safety. Our machinery is designed with user-friendly interfaces and intuitive controls, empowering operators to maximize productivity while minimizing the risk of accidents. The safety of our operators and customers is paramount, and we continuously strive to enhance the safety features of our machines.As we look towards the future, we remain dedicated to pushing the boundaries of innovation in the construction industry. With a strong focus on research and development, we aim to deliver groundbreaking solutions that continue to redefine the way we build. Together with our valued partners, we forge ahead, shaping the future of construction one project at a time.

Steel Roll Forming Machine: A Revolution in Construction Industry

Title: Innovative Metal Forming Machine Revolutionizes Steel Roll ManufacturingIntroduction:Steel roll manufacturing has witnessed a significant breakthrough with the introduction of a cutting-edge metal forming machine. This revolutionary technology, developed by leading industry experts {}, promises to redefine the process of producing high-quality IBR color steel rolls. The advanced capabilities and efficiency of this machine are set to transform the steel roll manufacturing sector, enabling companies to meet the growing demands of various industries.Body:1. Traditional Challenges and Limitations:Metal forming for IBR color steel rolls has traditionally been a time-consuming and labor-intensive process. The conventional methods involve multiple stages of manual labor, leading to inconsistencies, lower production rates, and increased costs. These limitations have hindered the growth and scalability of the industry.2. Introduction of the Innovative Metal Forming Machine:Recognizing the need for a more efficient and streamlined manufacturing process, {} has developed a state-of-the-art metal forming machine. This technology integrates cutting-edge automation and precision engineering to facilitate the seamless production of IBR color steel rolls.3. Advanced Features and Capabilities:The newly developed machine boasts a range of advanced features that deliver exceptional performance and consistency. Its state-of-the-art control system enables precise adjustments of critical parameters, ensuring the production of consistently high-quality IBR color steel rolls. The machine also incorporates an intelligent material feeding system that optimizes material usage, minimizing waste and enhancing overall efficiency.4. Increased Production Efficiency:With the implementation of this innovative metal forming machine, the production efficiency of IBR color steel rolls is set to increase significantly. The automated processes eliminate manual errors and ensure consistent quality throughout the manufacturing process. The machine's high-speed operation enables faster production rates, meeting market demand swiftly and effectively.5. Enhanced Design Flexibility:The metal forming machine allows for greater design flexibility, enabling the production of IBR color steel rolls in various shapes, sizes, and colors. This flexibility has wide-ranging implications for diverse industries, such as construction, automotive, and manufacturing, as it enables the manufacture of customized steel rolls to meet specific project requirements.6. Cost-effectiveness and Sustainability:The advanced automation and optimization features of the metal forming machine contribute to cost reduction and sustainability. With reduced labor requirements and minimized material waste, manufacturers can achieve higher profitability while reducing their carbon footprint. This technological advancement aligns with the global industry's increasing focus on sustainable production practices.7. Market Impact and Future Prospects:The introduction of this groundbreaking metal forming machine is poised to revolutionize the IBR color steel roll manufacturing industry. Its ability to streamline production processes, improve quality, and increase design flexibility will positively impact market competitiveness and growth. Furthermore, it opens up new opportunities for steel roll manufacturers to explore a wider range of applications and cater to evolving customer requirements.Conclusion:The introduction of the advanced metal forming machine by {} promises to transform the steel roll manufacturing industry. Its cutting-edge features, enhanced efficiency, design flexibility, and sustainability aspects position it as a game-changer in the market. With this innovative technology at their disposal, manufacturers can drive growth, meet rising demands, and deliver superior quality IBR color steel rolls to various industries.

Roll Forming Machine for Color Steel Production

Title: Advanced Color Steel Roll Forming Machine Revolutionizes the Steel Manufacturing IndustryIntroduction:With an ever-increasing demand for high-quality and sustainable construction materials, the global steel manufacturing industry has witnessed a significant technological advancement. The latest state-of-the-art Color Steel Roll Forming Machine has emerged as a game-changer, enabling efficient and precision-based production of color steel rolls.This groundbreaking technology, developed by a pioneering company committed to innovation and excellence in steel manufacturing, promises to revolutionize the industry. Designed to streamline the production process while reducing costs and enhancing product quality, this advanced roll forming machine is set to reshape the construction landscape.Streamlined Production Process:The Color Steel Roll Forming Machine automates and streamlines the manufacturing process for color steel rolls. It eliminates the need for manual labor, increasing both efficiency and productivity. With its fully automated operation, the machine can consistently produce high-quality, dimensionally accurate steel rolls at a significantly faster rate than traditional methods.Furthermore, this cutting-edge machine incorporates various advanced features such as automatic feeding, precision cutting, and accurate bending, ensuring a flawless end product. Additionally, it offers enhanced flexibility, allowing manufacturers to produce different profiles and sizes of color steel rolls as per customized requirements.Cost Efficiency and Reduced Waste:The Color Steel Roll Forming Machine is equipped with highly efficient energy-saving technologies. By optimizing power consumption and reducing material waste, it offers significant cost savings for manufacturers. The machine's ability to minimize production errors and material wastage ensures that each roll is utilized efficiently, thereby reducing overall expenses.Moreover, the advanced control system in the machine enables real-time monitoring and adjustment of production parameters. This not only enhances operational efficiency but also minimizes the need for manual intervention, further reducing labor costs.Environmental Sustainability:In line with the growing global focus on sustainability, the Color Steel Roll Forming Machine contributes to environmentally friendly manufacturing practices. Its energy-efficient design reduces carbon emissions and lowers the overall environmental footprint of the manufacturing process.Additionally, the machine's high precision and quality control mechanism ensure minimal material wastage, promoting sustainable resource management. By adopting this advanced technology, steel manufacturers can significantly reduce their impact on the environment and contribute to a greener future.Implications for the Steel Manufacturing Industry:The advent of the Color Steel Roll Forming Machine heralds a new era in the steel manufacturing industry. Its introduction is expected to bring about a multitude of benefits for manufacturers, contractors, and end-users alike.For manufacturers, the integration of this advanced technology allows for increased production capacity and reduced operational costs. The ability to produce a wide range of steel roll profiles opens up new market opportunities, catering to diverse customer demands.Contractors and construction firms benefit from the enhanced quality, precision, and efficiency of color steel rolls. These rolls, produced using the roll forming machine, exhibit superior durability, resistance to corrosion, and aesthetic appeal. The higher strength and reduced maintenance of color steel rolls significantly contribute to the longevity and sustainability of construction projects.Conclusion:The Color Steel Roll Forming Machine, developed by a leading company in steel manufacturing, represents a revolutionary leap forward in the industry. Its automated and efficient production process, coupled with cost-saving measures and environmental sustainability aspects, makes it the perfect solution for the evolving construction landscape.As more manufacturers integrate this advanced technology into their production lines, the steel manufacturing industry is poised to witness unparalleled growth and progress. The Color Steel Roll Forming Machine paves the way for a future where high-quality, sustainable, and economically viable construction materials become the norm, supporting the ever-growing infrastructure needs of our global society.

Highly Efficient Metal Profile Forming Equipment Offers Exceptional Quality

Color Steel Profile Forming Equipment: Revolutionizing the Construction IndustryIn recent years, the construction industry has witnessed significant advancements in technology and machinery. One such technological innovation that has revolutionized the industry is the Color Steel Profile Forming Equipment. This state-of-the-art machinery has transformed the way steel profiles are manufactured, improving efficiency and productivity like never before.Color Steel Profile Forming Equipment is a sophisticated machine that is designed to produce high-quality steel profiles with precision and speed. It is commonly used in the manufacturing of roofing, cladding, and façade systems. The equipment is capable of shaping steel sheets into various profiles as per the requirements of the construction project.The process begins by feeding the steel sheet into the machine, where it is then passed through a series of rollers. These rollers exert pressure on the sheet, gradually forming it into the desired profile. The Color Steel Profile Forming Equipment allows for accurate and consistent shaping of the profiles, ensuring that they meet the required specifications.What sets the Color Steel Profile Forming Equipment apart from other similar machinery is its advanced features and capabilities. This equipment utilizes cutting-edge technology to enhance its performance and efficiency. Some of its key features include:1. Automatic Control System: The Color Steel Profile Forming Equipment is equipped with an advanced automatic control system. This system allows for easy programming and monitoring of the machine's operations. It provides real-time information on the status of the equipment, ensuring that it operates smoothly and efficiently.2. High-Speed Production: With the Color Steel Profile Forming Equipment, manufacturers can significantly increase their production capacity. The machine is designed to work at high speeds, ensuring quick and efficient manufacturing of steel profiles. This translates into cost savings and faster project completion times.3. Versatile Profile Options: The Color Steel Profile Forming Equipment offers a wide range of profile options. It can produce profiles of varying sizes, shapes, and designs, catering to the diverse needs of the construction industry. This versatility allows for greater customization and flexibility, enabling architects and designers to bring their visions to life.A company at the forefront of this technological revolution is {}. With their extensive experience and expertise in the construction machinery industry, they have successfully developed and commercialized the Color Steel Profile Forming Equipment. Their commitment to innovation and quality has made them a trusted name in the market.With the Color Steel Profile Forming Equipment, {} has enabled countless construction companies to streamline their operations and achieve higher productivity. The machine's precision and efficiency have garnered praise from customers who have witnessed the significant improvements in their manufacturing processes.Moreover, {} offers comprehensive after-sales services and technical support, ensuring that their customers maximize the benefits of the Color Steel Profile Forming Equipment. They provide training programs and maintenance assistance to help operators and maintenance personnel effectively operate and maintain the machinery.In conclusion, the Color Steel Profile Forming Equipment has emerged as a game-changer in the construction industry. Its advanced features and capabilities have revolutionized the way steel profiles are manufactured, leading to increased efficiency, productivity, and cost savings for construction companies. With companies like {} at the helm, the future of construction machinery looks promising, promising a more technologically advanced and efficient industry.

Discover the Robust Efficiency of Advanced Color Steel Roll Forming Machine in the News

Title: Innovative Steel Roll Forming Machine Revolutionizes the Construction IndustryIntroduction:The manufacturing industry continues to witness remarkable technological advancements that revolutionize various sectors, including construction. Among such groundbreaking innovations, the development of the state-of-the-art Ibr Color Steel Roll Forming Machine has emerged as a game-changer in enhancing efficiency, cost-effectiveness, and quality in steel product manufacturing. With its superior functionality and precision, the machine promises to bring unprecedented benefits to construction companies and the broader infrastructure development sector.Enhancing Construction Efficiency:The Ibr Color Steel Roll Forming Machine streamlines the production process, significantly improving efficiency in the construction industry. Empowered by advanced automation and cutting-edge robotics, the machine provides a seamless manufacturing experience with minimal human intervention. Its carefully designed roll forming mechanism ensures precise and consistent product output, reducing production time and minimizing wastage. By optimizing the manufacturing process, construction companies can meet their project timelines more efficiently and contribute to the overall growth of the industry.Unparalleled Quality and Durability:One of the standout features of the Ibr Color Steel Roll Forming Machine lies in its ability to deliver exceptional quality and durability in steel products. By utilizing high-quality raw materials and incorporating advanced engineering techniques, the machine guarantees the production of uniform and aesthetically appealing steel rolls. These rolls exhibit superior strength, resistance to corrosion, and exceptional thermal insulation properties, making them an ideal choice for various construction applications. The machine's precise control over the roll forming process eliminates defects and inconsistencies, ensuring that each product meets stringent quality standards.Flexibility in Design and Customization:The Ibr Color Steel Roll Forming Machine empowers construction companies with versatile design and customization options. The machine can produce steel rolls in a wide range of shapes, profiles, and sizes, catering to the diverse requirements of different construction projects. From roofing sheets to insulated wall panels, the machine enables builders to achieve unique and attractive architectural designs. Its ability to adapt to specific project demands promotes creativity and facilitates the integration of steel products seamlessly into diverse construction applications.Cost-Effectiveness and Environmental Sustainability:Adopting the Ibr Color Steel Roll Forming Machine offers construction companies significant cost savings in the long run. By eliminating the need for extensive manual labor and reducing raw material wastage, the machine enhances production efficiency, leading to reduced manufacturing costs. Additionally, its energy-efficient operation contributes to reduced energy consumption, resulting in lower operational expenses. Furthermore, the machine promotes environmental sustainability through its reliance on eco-friendly manufacturing practices, including the reduction of harmful emissions and waste generation.Partnership with Construction Companies:In recognition of its potential to transform the industry, prominent steel roll forming machine manufacturers are partnering with construction companies to facilitate a smoother adoption process of the Ibr Color Steel Roll Forming Machine. These partnerships include comprehensive training programs for construction professionals, ensuring their familiarity with the machine's features, functionality, and maintenance requirements. By fostering collaborations between manufacturers and builders, the industry can effectively capitalize on the machine's benefits and usher in a new era of innovation and growth.Conclusion:The advent of the Ibr Color Steel Roll Forming Machine marks a significant leap forward in the construction industry's quest for efficiency, quality, and sustainability. With its ability to streamline manufacturing processes, deliver superior product quality, offer design flexibility, reduce costs, and contribute to environmental sustainability, this cutting-edge machine is poised to transform the steel product manufacturing landscape. Its potential to revolutionize the construction industry is undeniable, making it a crucial tool for companies aiming to stay ahead in an increasingly competitive market.

Efficient Three Layers Color Steel Roll Forming Machine Unveiled

Three Layers Color Steel Roll Forming Machine Revolutionizes Steel ManufacturingThe global steel industry has undergone a remarkable transformation with the introduction of advanced manufacturing technologies. One such innovation that is making waves in the industry is the Three Layers Color Steel Roll Forming Machine. This state-of-the-art machinery has not only enhanced production efficiency but has also set a new standard for product quality.The Three Layers Color Steel Roll Forming Machine, developed by an industry-leading company, is engineered to meet the growing demands of the construction and manufacturing sectors. With its cutting-edge features and unparalleled performance, it has gained significant attention and positive feedback from experts and clients alike.This advanced roll forming machine is the result of extensive research and development, bringing together the latest technology and the expertise of engineers. Its innovative design allows for the production of high-quality color steel sheets in a fast and efficient manner. The machine operates seamlessly, enabling the continuous formation of the steel sheets with accuracy and precision.Unlike traditional roll forming machines, the Three Layers Color Steel Roll Forming Machine offers a unique triple-layer configuration. This configuration enables the production of color steel sheets with enhanced durability and strength. It involves the simultaneous formation of three layers of steel, combining different colors to provide an aesthetically pleasing finish.One of the standout features of this machine is its versatility. It has the capability to produce a wide range of color steel sheets, catering to various architectural and industrial requirements. This flexibility, coupled with its high-speed production capacity, makes it an ideal solution for companies in need of fast and reliable steel manufacturing equipment.Furthermore, the Three Layers Color Steel Roll Forming Machine is equipped with advanced control systems that ensure precise and consistent product output. Through its user-friendly interface, operators have easy access to different parameters, allowing for customization and adjustment as per the desired specifications. This versatility empowers manufacturers to meet the specific demands of their clients while maintaining the highest standards of quality.The incorporation of the Three Layers Color Steel Roll Forming Machine in the production process offers numerous benefits. Firstly, it significantly reduces production costs by optimizing workflow and minimizing manual labor. The high-speed operation of the machine enables rapid production, enabling companies to meet tight deadlines and maximize production capacity.Secondly, the triple-layer configuration of the machine enhances the structural integrity and durability of the color steel sheets. This not only ensures the longevity of the products but also increases their resistance to adverse weather conditions, corrosion, and other external factors. This makes the sheets ideal for a wide range of applications, including roofing, wall cladding, and industrial structures.Lastly, the Three Layers Color Steel Roll Forming Machine contributes to sustainable manufacturing practices. With its efficient use of resources and minimal waste generation, it aligns with the growing global focus on environmental responsibility. This aspect makes it an attractive option for companies aiming to reduce their carbon footprint and contribute to a greener future.In conclusion, the advent of the Three Layers Color Steel Roll Forming Machine has revolutionized the steel manufacturing industry. Its cutting-edge technology, combined with its versatility and efficiency, has set a new benchmark for product quality and production speed. As more companies recognize its benefits, the machine is poised to become an indispensable asset in the global steel market, driving growth and innovation in the years to come.

Practical and User-Friendly Solar Panel Mounting Bracket Roll Forming Machine Revealed in Latest News

In today's ever-evolving world, the need for sustainable and clean energy solutions has become more apparent than ever. Solar power, in particular, has emerged as a viable alternative to traditional energy sources, and as a result, there has been a surge in the demand for solar panels and other related equipment. One such piece of machinery that has gained significant popularity is the Solar Panel Mounting Bracket Roll Forming Machine.The Solar Panel Mounting Bracket Roll Forming Machine, also known as the Solar Support Forming Machine, is an innovative and practical solution designed for the efficient production of solar panel mounting brackets. This machine combines advanced technology with ease of use, ensuring a seamless and hassle-free manufacturing process.One of the key highlights of the Solar Panel Mounting Bracket Roll Forming Machine is its electrical controlling cabinet, which allows for easy control and operation. This feature ensures that even individuals with limited technical knowledge can operate the machine effectively. With just a push of a button, the electrical controlling cabinet enables users to adjust various parameters, such as speed, angle, and length, to meet their specific manufacturing requirements.Furthermore, the Solar Panel Mounting Bracket Roll Forming Machine is characterized by its high precision and accuracy. This machine utilizes a roll forming process, which involves feeding a continuous strip of metal through a series of rollers to gradually shape it into the desired profile. This method ensures consistent results and minimizes material waste, reducing costs and maximizing productivity.The Solar Panel Mounting Bracket Roll Forming Machine is also known for its versatility. It can produce a wide range of solar panel mounting brackets, suitable for various installation scenarios and panel types. Whether it's ground-mounted, roof-mounted, or pole-mounted systems, this machine can meet all project requirements efficiently.Moreover, the Solar Panel Mounting Bracket Roll Forming Machine is manufactured by a reputable company with expertise in the field of roll forming technology. This company, known for its excellence in engineering and manufacturing, is recognized globally for delivering top-quality products and services to its clients. The company's commitment to innovation and customer satisfaction sets it apart from its competitors, making it a trusted and reliable choice for solar panel manufacturers.The adoption of the Solar Panel Mounting Bracket Roll Forming Machine offers numerous benefits to solar panel manufacturers. Its ease of use, coupled with advanced features such as the electrical controlling cabinet, enables manufacturers to streamline their production processes and increase efficiency. This, in turn, translates into enhanced productivity, reduced production costs, and ultimately, improved profitability.Furthermore, the adoption of solar power as an alternative energy source contributes to a cleaner and greener environment. By investing in state-of-the-art machinery like the Solar Panel Mounting Bracket Roll Forming Machine, manufacturers are taking a step towards sustainable growth and promoting the use of renewable energy.In conclusion, the Solar Panel Mounting Bracket Roll Forming Machine is an essential tool for solar panel manufacturers in the pursuit of cleaner and sustainable energy solutions. Its advanced features, ease of use, and precision make it an invaluable asset for any manufacturing facility. By investing in this practical and efficient machine, manufacturers can significantly improve their productivity, reduce costs, and contribute to a greener future.

Revolutionary Fully Automatic Color Steel Roll Forming Machine Unveiled in Latest News

Fully Automatic Roll Forming Machine Revolutionizes Color Steel ProductionWith the constant innovation and development in the manufacturing sector, a new breakthrough has been achieved with the introduction of the fully automatic roll forming machine for color steel. This state-of-the-art technology is set to revolutionize the production process and enhance the efficiency and quality of color steel production.Color steel, also known as pre-painted steel, has gained immense popularity in various industries due to its versatility, durability, and aesthetic appeal. It is widely used in the construction of roofs, walls, and other structural components. Traditionally, color steel production involved manual labor that required considerable time and effort. However, with the advent of fully automatic roll forming machines, the production process has become significantly faster, more precise, and cost-effective.The innovative features of this advanced machine eliminate the need for manual intervention, resulting in increased productivity and reduced error rates. The roll forming machine operates seamlessly, starting from the loading of steel coils to the final product, with minimal human involvement. The machine incorporates cutting-edge technology that ensures precise shaping, bending, and cutting of the steel sheets, resulting in perfectly formed color steel components.One of the key advantages of the fully automatic roll forming machine is its ability to handle a wide range of color steel materials, including galvanized steel, galvalume steel, and various coated steel sheets. This flexibility allows manufacturers to cater to the diverse needs of their customers and offer a wide range of color options. The machine can effortlessly produce color steel profiles of various shapes and sizes, meeting the requirements of different construction projects.Furthermore, the fully automatic roll forming machine is equipped with an intelligent control system that enables smooth and efficient operation. The control system allows operators to set precise parameters, monitor the production process in real-time, and make adjustments as needed. This ensures consistent quality and minimizes material wastage, further optimizing the production efficiency.In addition to its operational efficiency, the fully automatic roll forming machine also prioritizes worker safety. With its advanced safety features and protective measures, the machine significantly reduces the risk of accidents and injuries during the production process. This creates a safer working environment and improves overall worker morale and satisfaction.As a leader in the manufacture and supply of roll forming machines, [Company Name] has introduced this cutting-edge technology to the market. The company's commitment to research and development has enabled them to design and produce machinery that meets the evolving needs of the industry. With extensive experience and expertise, [Company Name] has become a trusted name in the roll forming machine industry.The introduction of the fully automatic roll forming machine by [Company Name] signifies a leap forward in color steel production. This technology revolutionizes the manufacturing process, bringing numerous benefits to manufacturers, construction companies, and end-users alike. The increased speed, precision, and quality of color steel production will contribute to the advancement of the construction industry and fuel economic growth.In conclusion, the fully automatic roll forming machine has emerged as a game-changer in the color steel production industry. Its advanced features, efficient operation, and focus on worker safety make it an invaluable asset for manufacturers. With [Company Name] at the forefront of this technology, the future of color steel production is brighter than ever.

Application Characteristics of Color Steel Glazed Tile Roll Forming Machine: A Comprehensive Analysis

Color Steel Glazed Tile Roll Forming Machine: A Must-Have for the Construction IndustryThe construction industry has seen significant growth over the years. The demand for better-quality buildings has led to the development of new construction technologies. One such technology that has gained tremendous popularity is the use of color steel glazed tiles for roofing. The reason color steel glazed tiles have become a preferred choice for roofing is because of their durability, strength, and excellent appearance.To manufacture these tiles, the industry requires a reliable color steel glazed tile roll forming machine. These machines have become quite prevalent in the construction sector due to the high demand for color steel glazed tiles. If you are looking for a reliable color steel glazed tile roll forming machine, then look no further than Zhejiang Jinggong Science & Technology Co., Ltd.Application CharacteristicsThe color steel glazed tile roll forming machine is designed to produce high-quality glazed tiles used for roofing. The machine is easy to use and operate, consisting of several parts, including a feed introduction platform, a forming host, a die pressing device, a forming and shearing device, a hydraulic station, and a computer control system. The machine is capable of producing color steel glazed tiles of different shapes and sizes, based on the client requirements.One of the notable features of this machine is its accuracy and precision. It guarantees that every tile produced is of the same high standard and quality. The machine is also energy-efficient, which means it consumes less power compared to similar machines in the market. It has a low maintenance cost, which makes it a cost-effective investment for businesses in the construction industry.Color Steel Roofing Roll Forming MachineZhejiang Jinggong Science & Technology Co., Ltd. provides a wide range of color steel roofing roll forming machines for clients in the construction industry. These machines are designed to manufacture roofing sheets with varying shapes, sizes, and thicknesses. The machines are easy to use and operate, thanks to their user-friendly interface.The company's color steel roofing roll forming machines are designed using the latest technology to ensure high-quality, durable, and consistent products. The machines have a high production capacity, which means they can manufacture a large number of roofing sheets in a short period. They are also energy-efficient, with low maintenance costs, making them a valuable investment for businesses in the construction industry.ConclusionThe use of color steel glazed tiles for roofing in the construction industry has become increasingly popular due to their durability, strength, and excellent appearance. To manufacture these tiles, businesses require a reliable color steel glazed tile roll forming machine. Zhejiang Jinggong Science & Technology Co., Ltd. provides the perfect solution for this need by offering high-quality and energy-efficient machines.The company's color steel roofing roll forming machines are designed to produce roofing sheets of different shapes, sizes, and thicknesses. They are durable, high-quality, easy to operate, and are an excellent investment for businesses in the construction industry. So, if you are looking for a reliable, efficient, and high-quality color steel roofing roll forming machine, look no further than Zhejiang Jinggong Science & Technology Co., Ltd.

Revolutionary Technology Takes Color Steel Profile Manufacturing to the Next Level

Color Steel Profile Manufacturing Machine: Revolutionizing the Construction IndustryIn an era where technological innovations continue to transform various industries, the construction sector is not far behind. One such groundbreaking development is the introduction of the Color Steel Profile Manufacturing Machine, a game-changer that has revolutionized the steel manufacturing process. This cutting-edge equipment has not only improved efficiency but has also enhanced product quality, making it a preferred choice for numerous construction projects worldwide.The Color Steel Profile Manufacturing Machine, developed by an industry-leading company specializing in steel manufacturing equipment, has gained tremendous popularity within a short span of time. Founded in [year of establishment], the company has quickly emerged as a frontrunner in this niche market due to their relentless commitment to research and development, customer-centric approach, and dedication to delivering innovative solutions.The color steel profile manufacturing process begins with the raw materials. The machine can work with a range of materials, including galvanized steel, stainless steel, and aluminum, providing flexibility to cater to diverse project requirements. The company's proficiency in material selection and customization allows them to develop profiles that are not only aesthetically pleasing but also durable and resilient, ensuring longevity and resistance to external factors such as corrosion and weather fluctuations.One of the key advantages of the Color Steel Profile Manufacturing Machine is its advanced automation capabilities. This state-of-the-art equipment is equipped with sophisticated sensors, precision controllers, and cutting-edge software, enabling it to operate with minimal human intervention. This reduces the risk of errors, optimizes production time, and enhances overall efficiency. The machine's automated processes also contribute to cost reduction, as it eliminates the need for extensive manual labor.In addition to its automation capabilities, the Color Steel Profile Manufacturing Machine boasts remarkable precision and accuracy in profile creation. The company's team of experienced engineers and technicians ensures that each profile is meticulously designed and manufactured to meet the highest industry standards. The machine's advanced technology enables it to produce profiles with consistent dimensions, sharp edges, and smooth finishes, guaranteeing a flawless final product.Furthermore, the Color Steel Profile Manufacturing Machine prioritizes environmental sustainability. The company's commitment to green manufacturing practices is reflected in the machine's energy-efficient operations. By employing energy-saving technologies and optimizing resource utilization, the machine minimizes its carbon footprint, making it an eco-friendly choice for environmentally conscious construction projects.The versatility of the Color Steel Profile Manufacturing Machine is yet another notable feature. With the ability to produce a wide range of profiles, such as roofing sheets, wall panels, floor decking, and ceiling systems, this equipment caters to the diverse needs of the construction industry. Its adaptability allows architects and builders to bring their creative visions to life, facilitating the realization of unique and striking architectural designs.As the construction industry continues to evolve, the demand for efficient and high-quality steel manufacturing equipment is on the rise. The Color Steel Profile Manufacturing Machine stands at the forefront of this technological leap, offering a myriad of benefits to various stakeholders, including manufacturers, contractors, and end-users. Its advanced features, precision engineering, eco-friendly operations, and versatility make it an indispensable tool for the modern construction industry.In conclusion, the Color Steel Profile Manufacturing Machine is a remarkable innovation that has transformed the steel manufacturing process. With its advanced automation, precision engineering, environmental sustainability, and versatility, this equipment has become an indispensable asset for construction projects worldwide. As the industry evolves, this game-changing machine continues to redefine the future of steel profile manufacturing, offering endless possibilities for architects, builders, and construction companies alike.