High-quality Color Steel Roll Forming Machine for Sale - Complete Guide

By:Admin

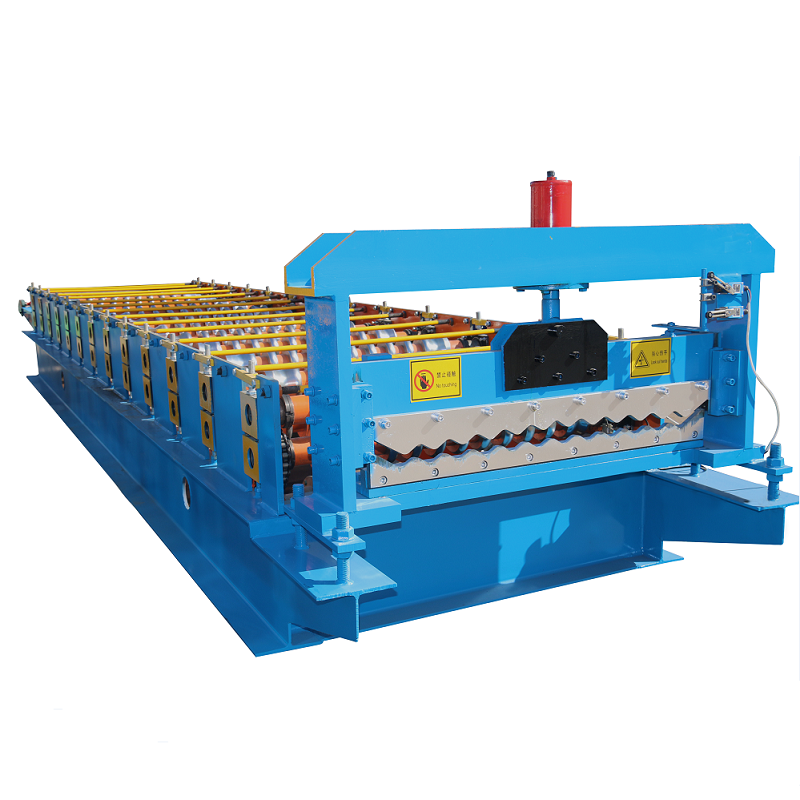

The company behind this innovative machine is a leader in the manufacturing and distribution of industrial equipment. With years of experience and expertise in the industry, the company has continuously developed and improved its products to meet the changing needs of its customers. The introduction of the GP GI Color Steel Roll Forming Machine is a testament to the company's dedication to innovation and excellence.

The machine is designed to produce galvanized and colored steel sheets with precision and speed. It is equipped with advanced technology that allows for quick and accurate roll forming, ensuring that the finished products meet the highest standards of quality. The machine's automatic control system and high-speed production capabilities make it an ideal choice for manufacturers and contractors who require large quantities of steel sheets for their projects.

One of the key features of the GP GI Color Steel Roll Forming Machine is its versatility. It is capable of producing a wide range of steel sheet profiles, including corrugated, trapezoidal, and other custom designs. This flexibility allows for greater customization and adaptability to the specific requirements of different construction projects. With this machine, manufacturers and contractors no longer have to rely on pre-made steel sheets, as they can now produce their own customized designs on site.

In addition to its speed and versatility, the machine is also known for its durability and reliability. It is built to withstand the rigors of continuous operation, ensuring minimal downtime and maximum productivity. The robust construction of the machine, combined with its advanced safety features, makes it a suitable choice for high-volume production environments.

Furthermore, the company provides comprehensive support and services for the GP GI Color Steel Roll Forming Machine. From installation and training to maintenance and repairs, the company's team of experts is committed to ensuring that customers get the most out of their investment. This includes regular updates and upgrades to the machine's software and hardware, as well as ongoing technical support to address any issues or concerns that may arise.

The introduction of the GP GI Color Steel Roll Forming Machine marks a significant advancement in the steel manufacturing industry. Its cutting-edge technology and advanced features set a new standard for efficiency and quality in the production of galvanized and colored steel sheets. With its speed, accuracy, versatility, and durability, this machine is poised to make a lasting impact on the construction industry.

In conclusion, the GP GI Color Steel Roll Forming Machine is a game-changer for manufacturers and contractors who demand the best in steel sheet production. With its advanced technology, speed, versatility, and reliability, this machine is set to redefine the way steel sheets are manufactured and used in construction projects. The company's commitment to innovation and excellence, combined with its comprehensive support and services, makes it an ideal partner for those looking to elevate their steel manufacturing capabilities. As the industry continues to evolve, the GP GI Color Steel Roll Forming Machine will undoubtedly play a pivotal role in shaping its future.

Company News & Blog

High-quality Solar Mounting Structure Roll Forming Machine for Color Steel

Color Steel Solar Mounting Structure Roll Forming Machine is a cutting-edge technology that promises to revolutionize the solar energy industry. This machine is designed to efficiently produce high-quality mounting structures for solar panels, making the installation process faster and more cost-effective.The Color Steel Solar Mounting Structure Roll Forming Machine is a game-changer in the renewable energy sector. It is a fully automated, high-speed machine that can produce a wide range of mounting structures for solar panels. This machine is equipped with advanced technology and precision engineering, ensuring that each mounting structure is produced with the highest level of accuracy and quality.One of the key features of the Color Steel Solar Mounting Structure Roll Forming Machine is its ability to efficiently roll-form color steel sheets into precise shapes and sizes. This ensures that the mounting structures are strong, durable, and able to withstand harsh weather conditions. The machine is also capable of producing mounting structures in various designs and configurations, allowing for customization based on specific project requirements.In addition to its capabilities, the Color Steel Solar Mounting Structure Roll Forming Machine is designed for easy operation and maintenance. It can be easily operated by a single operator, and its modular design allows for quick and simple maintenance and repairs.The company behind the Color Steel Solar Mounting Structure Roll Forming Machine, has been a leader in the manufacturing of roll forming equipment for over 20 years. The company has a strong track record of delivering high-quality, innovative products to the market, and the Color Steel Solar Mounting Structure Roll Forming Machine is no exception.The company's commitment to innovation and excellence is evident in the design and performance of the Color Steel Solar Mounting Structure Roll Forming Machine. The machine is built to the highest industry standards, ensuring reliable and consistent performance for years to come.The Color Steel Solar Mounting Structure Roll Forming Machine is already making waves in the solar energy industry, with a growing number of companies adopting this technology for their solar panel installation projects. The machine is being praised for its ability to reduce production time and costs, ultimately making solar energy more accessible and affordable.In addition to its impact on the solar energy industry, the Color Steel Solar Mounting Structure Roll Forming Machine is also contributing to the global shift towards renewable energy sources. By making solar energy more efficient and cost-effective, this technology is helping to reduce reliance on fossil fuels and mitigate the impact of climate change.With the Color Steel Solar Mounting Structure Roll Forming Machine, the company is once again demonstrating its commitment to driving innovation and progress in the renewable energy sector. This technology is set to play a critical role in the widespread adoption of solar energy, and its benefits will be felt by businesses, homeowners, and the environment alike.As the demand for solar energy continues to grow, advancements like the Color Steel Solar Mounting Structure Roll Forming Machine will be instrumental in driving the industry forward. With this technology, solar energy is becoming more accessible, reliable, and cost-effective than ever before.In conclusion, the Color Steel Solar Mounting Structure Roll Forming Machine is a testament to the company's dedication to advancing the renewable energy sector. This technology is revolutionizing the way solar panels are installed, and its impact will be felt for years to come. As the world continues to transition towards clean, sustainable energy sources, advancements like the Color Steel Solar Mounting Structure Roll Forming Machine will be key in driving this global shift.

High-Quality Colored Metal Steel Sheet Roll Forming Machine for Sale

The engineering company is proud to announce their latest innovation in the field of metal forming technology: the Colored Metal Steel Sheet Roll Forming Machine. This state-of-the-art machine is set to revolutionize the metal forming industry with its cutting-edge features and high production efficiency.The Colored Metal Steel Sheet Roll Forming Machine is designed to produce high-quality colored metal steel sheets with precision and speed. With its advanced technology and innovative design, this machine is capable of producing a wide range of colored metal steel sheets that meet the highest industry standards.One of the key features of this machine is its ability to efficiently roll form colored metal steel sheets in various thicknesses and widths. This means that manufacturers can easily produce customized colored metal steel sheets according to their specific requirements, without compromising on quality or performance.In addition, the Colored Metal Steel Sheet Roll Forming Machine is equipped with a user-friendly interface that allows operators to easily control and adjust the production process. This ensures that the machine can be operated with minimal training, resulting in increased productivity and reduced downtime.Furthermore, the machine is designed for reliability and durability, ensuring continuous and trouble-free operation. This makes it an ideal investment for manufacturers looking to streamline their production processes and enhance their overall efficiency.The company's dedication to innovation and excellence is reflected in the development of the Colored Metal Steel Sheet Roll Forming Machine. With over [number of years] of experience in the engineering industry, the company has established itself as a leading provider of metal forming solutions.From its humble beginnings, the company has grown to become a trusted name in the industry, known for its commitment to quality, reliability, and customer satisfaction. The introduction of the Colored Metal Steel Sheet Roll Forming Machine is a testament to the company's continuous pursuit of excellence and its ability to anticipate and meet the evolving needs of the market.The Colored Metal Steel Sheet Roll Forming Machine is set to make a significant impact in the metal forming industry, offering manufacturers a competitive edge in terms of production efficiency and product quality. Its innovative features, user-friendly interface, and robust construction make it a valuable addition to any manufacturing facility.The company's dedication to providing cutting-edge solutions to its customers is reflected in the development of the Colored Metal Steel Sheet Roll Forming Machine. With a focus on innovation, quality, and performance, the company continues to set new standards in the metal forming industry, solidifying its reputation as a leader in the field.As the manufacturing industry continues to evolve, the Colored Metal Steel Sheet Roll Forming Machine stands out as a game-changing solution that will empower manufacturers to meet the demands of a competitive market. With its advanced technology and user-friendly design, this machine is poised to set new benchmarks in metal forming technology.In conclusion, the Colored Metal Steel Sheet Roll Forming Machine represents a significant milestone for the company. Its introduction underscores the company's commitment to innovation, quality, and customer satisfaction. With its advanced features and high production efficiency, this machine is set to elevate the standards of the metal forming industry and empower manufacturers to achieve new levels of productivity and performance.

High-Quality Profile Forming Equipment for Color Steel Manufacturing

Color Steel Profile Forming Equipment is a crucial piece of machinery used in the manufacturing of color steel products, which are widely used in the construction industry for roofing, cladding, and other structural applications. The equipment is designed to efficiently and accurately form color steel profiles according to specific design requirements, allowing for the production of high-quality and precise components.{Company Name}, a leading manufacturer of Color Steel Profile Forming Equipment, has been at the forefront of innovation in the industry for over 20 years. With a focus on research and development, the company has continuously upgraded its technology and equipment to meet the changing needs of the market. Their color steel profile forming equipment is known for its reliability, precision, and high efficiency, making it a preferred choice for manufacturers around the world.The company’s Color Steel Profile Forming Equipment is designed for versatility, capable of producing a wide range of profiles including corrugated sheets, IBR sheets, and various custom profiles. The equipment is highly customizable, allowing for easy adjustment and configuration to meet specific production requirements. This flexibility is a key factor in the equipment’s popularity, as it allows manufacturers to adapt to changing market demands and produce a variety of products with the same machinery.One of the standout features of {Company Name}’s Color Steel Profile Forming Equipment is its advanced control system, which ensures precise and consistent forming of profiles. The system is user-friendly and intuitive, making it easy for operators to set up the equipment and monitor the production process. This level of automation not only increases efficiency but also reduces the margin for error, leading to higher quality end products.In addition to its technological advancements, {Company Name} places a strong emphasis on the durability and longevity of its equipment. The Color Steel Profile Forming Equipment is built to withstand the rigors of continuous operation, with high-quality components and materials used throughout the manufacturing process. This focus on durability ensures that the equipment is a long-term investment for manufacturers, providing reliable performance and minimal downtime.Furthermore, {Company Name} provides comprehensive customer support and after-sales service, ensuring that their clients are able to maximize the potential of their Color Steel Profile Forming Equipment. This includes training for operators, regular maintenance and servicing, as well as readily available spare parts. The company’s commitment to customer satisfaction has earned it a reputation for reliability and trustworthiness in the industry.With a strong track record of delivering high-quality Color Steel Profile Forming Equipment and a dedication to continuous improvement, {Company Name} has established itself as a leader in the market. Their equipment has been adopted by manufacturers in numerous countries, with a proven track record of reliability and performance. As the demand for color steel products continues to grow, {Company Name} is well-positioned to meet the needs of the industry with their innovative and reliable equipment.In conclusion, {Company Name}’s Color Steel Profile Forming Equipment represents a significant advancement in the manufacturing of color steel products, offering unparalleled precision, efficiency, and durability. With a focus on customer satisfaction and a commitment to innovation, the company has solidified its position as a trusted provider of quality equipment for the global construction industry. As the industry continues to evolve, {Company Name} remains at the forefront, driving progress and setting new standards for color steel profile forming technology.

Color Steel Roll Forming Machine for Single Layer Production

Single Layer Color Steel Roll Forming Machine Revolutionizes the Steel IndustryWith the rapid development of the construction industry, the demand for high-quality and efficient steel roll forming machines has been increasing. In response to this demand, [Company Name] has introduced a cutting-edge Single Layer Color Steel Roll Forming Machine that is set to revolutionize the steel industry.The newly developed Single Layer Color Steel Roll Forming Machine is equipped with advanced technology and state-of-the-art features, making it a game-changer in the production of color steel products. This machine is designed to effectively and efficiently produce single layer color steel roofing and wall panels, meeting the diverse needs of the construction industry.One of the key features of this machine is its precision and accuracy in forming color steel panels. The machine is equipped with high-precision rollers and automated control systems, ensuring the consistency and uniformity of the formed panels. This not only improves the overall quality of the products but also reduces material waste and production costs.Furthermore, the Single Layer Color Steel Roll Forming Machine is highly efficient and capable of producing a large volume of color steel panels in a short amount of time. Its high-speed operation and rapid production capabilities make it an ideal choice for large-scale construction projects and manufacturing facilities.In addition to its efficiency, the machine is also designed for ease of use and maintenance. It features a user-friendly interface and intuitive controls, allowing operators to easily set up and operate the machine with minimal training. Moreover, its durable and robust construction ensures long-term reliability and reduces the need for frequent maintenance.[Company Name] has a long-standing reputation for delivering high-quality and innovative machinery, and the introduction of the Single Layer Color Steel Roll Forming Machine further solidifies its position as a leader in the industry. The company has a team of skilled engineers and technicians dedicated to developing cutting-edge solutions that meet the evolving needs of the steel and construction industries.With its commitment to innovation and quality, [Company Name] aims to set new standards in the steel roll forming machinery market. The Single Layer Color Steel Roll Forming Machine is poised to redefine the production process of color steel panels, providing customers with a cost-effective, reliable, and efficient solution for their manufacturing needs.The introduction of the Single Layer Color Steel Roll Forming Machine comes at a time when the construction industry is experiencing a surge in demand for high-quality and durable color steel products. This machine not only meets this demand but also sets a new benchmark for precision, efficiency, and reliability in steel roll forming technology.In conclusion, the Single Layer Color Steel Roll Forming Machine from [Company Name] is a testament to the company's commitment to innovation and excellence. With its state-of-the-art features and advanced technology, this machine is set to revolutionize the steel industry and become the go-to solution for manufacturers and construction companies seeking high-quality color steel products.

Buy High-Quality Color Steel Roll Forming Machine for Your Roof Panels

Color Steel Roll Forming Machine: The Ultimate Solution for Roof Panel ManufacturingIn the rapidly evolving construction industry, the demand for durable and efficient roofing materials is ever-increasing. To meet this demand, manufacturers have turned to advanced machinery, such as the Color Steel Roll Forming Machine. In this blog post, we will explore the various aspects of this revolutionary piece of equipment and delve into its features that make it an indispensable tool for roof panel manufacturing. So, let's dive in!What is a Color Steel Roll Forming Machine?A Color Steel Roll Forming Machine is a specialized piece of equipment designed to transform flat, coiled steel into perfectly shaped roof panels. This machine utilizes a series of roller dies, which gradually bend and shape the steel as it passes through. The output is a quality product with uniform dimensions and excellent precision.Why Choose a Color Steel Roll Forming Machine?There are numerous advantages to using a Color Steel Roll Forming Machine for your roof panel manufacturing needs. Let's take a closer look at some of these key benefits:1. High Production Efficiency: The Color Steel Roll Forming Machine has the capability to produce roof panels at a remarkable speed. With automated operations and high line speeds, this machine ensures increased productivity while keeping the labor requirement to a minimum.2. Versatility: These roll forming machines have the flexibility to produce a wide range of roof panel profiles, allowing manufacturers to cater to various project requirements. Whether it's trapezoidal or corrugated profiles, the Color Steel Roll Forming Machine can deliver it all.3. Superior Product Quality: Precision is the name of the game in today's construction industry. With a Color Steel Roll Forming Machine, you can expect exceptional product quality, as it eliminates the inconsistencies that may arise from manual fabrication. The machine ensures correct panel dimensions, precise angles, and consistent bending, resulting in roof panels that are resistant to leaks, deformation, and corrosion.4. Cost-Effective Solution: Investing in a Color Steel Roll Forming Machine can lead to significant cost savings in the long run. By streamlining the manufacturing process and reducing wastage, manufacturers can optimize raw material utilization and minimize labor expenses. Moreover, the high-quality output from this machine reduces repair and maintenance costs for end-users.5. Enhanced Customization: With advanced control systems, a Color Steel Roll Forming Machine allows for easy adjustments to panel dimensions and shapes. This feature gives manufacturers the ability to accommodate customized orders and meet the specific requirements of different projects. Offering tailor-made solutions is crucial to maintaining a competitive edge in the market.Investing wisely in a Color Steel Roll Forming MachineChoosing the right Color Steel Roll Forming Machine can make a significant difference in the success of your roofing material manufacturing venture. To ensure a wise investment, consider the following factors:1. Machine Stability and Durability: Look for a machine constructed with high-quality materials and components for enhanced stability and longevity. A robust frame and reliable power transmission system are key to maintaining consistent performance over time.2. Cutting Mechanism: The roll forming machine should include a precise and efficient cutting mechanism to produce accurate panel lengths. Opt for machines equipped with advanced servo-driven cutting systems for smooth and clean cuts every time.3. Control System: An intuitive and user-friendly control system is crucial for smooth operation and quick programming changes. Ensure that the machine you choose offers excellent control options and is compatible with various computer systems.4. After-Sales Support: The reputation of the manufacturer is equally important. Before making a purchase, research the customer support services provided by the manufacturer. Look for a company that offers comprehensive after-sales support, including training, technical assistance, and spare parts availability.Conclusion:In the competitive world of roof panel manufacturing, a Color Steel Roll Forming Machine is a game-changer. This advanced machinery not only improves production efficiency but also delivers superior product quality, customization options, and cost savings. Investing in a reliable and high-performance Color Steel Roll Forming Machine is an essential step towards staying ahead in the market and satisfying customer demands. So, embrace this cutting-edge technology and elevate your roofing material manufacturing business to new heights!

High-Quality Steel Wall Panel Roll Forming Machine

Color Steel Wall Panel Roll Forming Machine Revolutionizing the Construction IndustryThe construction industry has experienced a significant transformation with the introduction of the innovative Color Steel Wall Panel Roll Forming Machine by a leading machinery manufacturer. This cutting-edge technology has revolutionized the way steel wall panels are produced, offering numerous benefits to the construction sector.The Color Steel Wall Panel Roll Forming Machine is designed to efficiently fabricate high-quality steel wall panels with precision and speed. It features advanced roll forming technology that allows for the seamless shaping of steel sheets into customized profiles and designs. The machine is capable of producing a wide range of wall panel styles, including corrugated, ribbed, and flat panels, catering to the diverse needs of construction projects.One of the most notable advantages of this state-of-the-art roll forming machine is its ability to streamline the production process. With automated operation and a high-speed production capability, the machine significantly reduces the time and labor required to manufacture steel wall panels. This not only enhances efficiency but also allows for greater output, enabling construction companies to meet project deadlines and demands more effectively.Furthermore, the Color Steel Wall Panel Roll Forming Machine offers exceptional precision and consistency in panel production. The machine is equipped with advanced control systems that ensure accurate profiling and dimensional uniformity, resulting in high-quality panels that meet industry standards. This level of precision is essential for construction projects where stringent quality requirements are paramount.In addition to its efficiency and precision, the Color Steel Wall Panel Roll Forming Machine is also known for its versatility. It can accommodate various sizes and thicknesses of steel sheets, allowing for the production of customized wall panels to suit specific project needs. This adaptability is immensely beneficial for architects and builders seeking to create unique and visually appealing facades for their structures.The introduction of this innovative roll forming machine has had a significant impact on the construction industry, offering a cost-effective and sustainable solution for steel wall panel production. By optimizing material usage and minimizing waste, the machine supports environmentally-friendly practices and contributes to the overall sustainability of construction projects.As a leading machinery manufacturer, {} has been at the forefront of developing and supplying advanced roll forming equipment to the global market. With a commitment to innovation and quality, the company has garnered a reputation for delivering cutting-edge solutions that enhance productivity and performance in various industries, including construction.{} has invested heavily in research and development to continuously improve its roll forming machines, including the Color Steel Wall Panel Roll Forming Machine. The company’s team of engineers and technical experts have worked tirelessly to refine the machine's design and functionality, ensuring that it meets the evolving needs of the construction sector.The success of the Color Steel Wall Panel Roll Forming Machine can be attributed to {}'s dedication to delivering reliable and efficient equipment that empowers businesses to thrive in a competitive marketplace. By prioritizing customer satisfaction and industry advancements, the company has earned the trust and loyalty of clients worldwide.Looking ahead, {} remains committed to advancing its roll forming technology and expanding its range of machinery to drive progress in the construction industry and beyond. With a focus on innovation and sustainability, the company is poised to continue shaping the future of manufacturing and construction with its cutting-edge solutions.In conclusion, the introduction of the Color Steel Wall Panel Roll Forming Machine has undoubtedly transformed the construction industry by offering a highly efficient, versatile, and sustainable solution for steel wall panel production. With its precision, speed, and adaptability, this innovative roll forming machine has set a new standard for quality and performance, empowering construction companies to elevate their capabilities and achieve remarkable results. As the industry evolves, {} remains at the forefront of innovation, driving progress and shaping the future of construction technology.

High-Quality Color Steel Roll Forming Machine Factory for Your Needs

Color Steel Roll Forming Machine Factory, a leading manufacturer of roll forming machines, has recently announced the launch of their latest product line which promises to revolutionize the industry. With their state-of-the-art technology and commitment to innovation, the company has solidified its position as a pioneer in the field of roll forming machines.Established in 2001, Color Steel Roll Forming Machine Factory has always been at the forefront of technological advancements in the industry. With a focus on producing high-quality, efficient and reliable roll forming machines, the company has earned a stellar reputation for delivering superior products to their customers around the world.The latest product line from Color Steel Roll Forming Machine Factory boasts cutting-edge features that are designed to enhance productivity and efficiency for their customers. With advanced automation and precision engineering, these machines are capable of producing high-quality steel rolls with unparalleled accuracy and speed. This level of precision and performance is a game-changer for manufacturers in various industries, including construction, automotive, and appliance manufacturing.In addition to their technical prowess, Color Steel Roll Forming Machine Factory also prides itself on its commitment to customer satisfaction. The company offers comprehensive after-sales service and technical support to ensure that their customers can maximize the potential of their roll forming machines. This dedication to customer care has earned Color Steel Roll Forming Machine Factory a loyal and satisfied customer base.One of the key features of the new product line is its flexibility and adaptability. Color Steel Roll Forming Machine Factory understands that different industries have varying requirements when it comes to roll forming, and their machines can be customized to meet these specific needs. This level of customization sets the company apart from its competitors, as it allows customers to tailor their machines to fit their exact manufacturing requirements.Furthermore, the new product line from Color Steel Roll Forming Machine Factory also incorporates eco-friendly features that align with the company's commitment to sustainability. By utilizing energy-efficient technology and optimizing material usage, these machines are designed to minimize environmental impact while maintaining high productivity levels. This focus on sustainability reflects Color Steel Roll Forming Machine Factory's dedication to responsible manufacturing practices and corporate citizenship.As the global demand for high-quality roll forming machines continues to grow, Color Steel Roll Forming Machine Factory is poised to capitalize on this trend with its innovative product line. The company's extensive experience and expertise in the industry position it as a trusted partner for manufacturers seeking reliable and efficient roll forming solutions.In conclusion, Color Steel Roll Forming Machine Factory's new product line represents a significant leap forward in the roll forming industry. With their cutting-edge technology, commitment to customer satisfaction, and dedication to sustainability, the company is well-positioned to lead the market and set new standards for roll forming machines. As the industry continues to evolve, Color Steel Roll Forming Machine Factory remains at the forefront, driving innovation and delivering excellence in roll forming technology.

High-quality Three Layers Color Steel Roll Forming Machine for Sale

Three Layers Color Steel Roll Forming Machine Revolutionizes the Metal Roofing IndustryAs the demand for durable and visually appealing roofing solutions continues to rise, companies are constantly seeking innovative technologies to improve their manufacturing processes. This has led to the development of the three layers color steel roll forming machine, a cutting-edge equipment that has revolutionized the metal roofing industry.This advanced roll forming machine is a product of extensive research and development by a leading industrial equipment manufacturer. Leveraging on their decades of experience and expertise in the field, the company has successfully designed a machine that offers unparalleled efficiency and precision in producing high-quality color steel roofing panels.The three layers color steel roll forming machine boasts a number of innovative features that set it apart from traditional roll forming equipment. One of its key advantages is its ability to create three layers of metal panels in a single pass, significantly reducing the production time and labor costs. This is made possible by the machine's unique design, which allows for seamless integration of multiple layers of different colors and materials.In addition, the machine is equipped with state-of-the-art technology that ensures precise shaping and cutting of the metal panels, resulting in uniform and flawless end products. This level of accuracy is crucial in the roofing industry, where any imperfections can compromise the integrity and aesthetics of the final installation.Furthermore, the three layers color steel roll forming machine is highly versatile and can accommodate a wide range of panel sizes and profiles, giving manufacturers the flexibility to meet the varying demands of their customers. This makes it an ideal solution for companies looking to expand their product offerings and cater to different market segments.The introduction of this advanced machinery has been met with enthusiasm by industry professionals, who recognize the significant impact it can have on their operations. With its ability to streamline the production process and improve product quality, the machine is poised to drive productivity and competitiveness in the metal roofing sector.In light of these developments, the company behind the three layers color steel roll forming machine is confident that it will gain a strong foothold in the market. Their commitment to innovation and continuous improvement reflects their dedication to meeting the evolving needs of their customers and supporting the growth of the metal roofing industry.Moreover, the company prides itself on providing comprehensive support and training to help manufacturers maximize the potential of their new equipment. This includes assistance with installation, maintenance, and troubleshooting, as well as ongoing technical guidance to ensure smooth and efficient operation of the machine.As the three layers color steel roll forming machine continues to gain traction in the market, it is expected to drive a new wave of advancements in the metal roofing industry. With its capability to enhance production efficiency and product quality, manufacturers will be well-positioned to meet the growing demand for durable and visually striking roofing solutions.In conclusion, the introduction of the three layers color steel roll forming machine represents a significant milestone in the evolution of the metal roofing industry. Its innovative design, precision engineering, and versatility have the potential to revolutionize the way metal roofing panels are manufactured, setting new standards for productivity and quality in the market. As companies embrace this cutting-edge technology, they can expect to see enhanced capabilities and opportunities for growth in the years to come.

High-Quality Solar Mounting Structure Roll Forming Machine for Color Steel

Color Steel Solar Mounting Structure Roll Forming Machine has been making waves in the industry for its cutting-edge technology and innovative design. This machine, produced by [Company Name], is revolutionizing the way solar mounting structures are manufactured, making the process faster, more efficient, and more cost-effective.The Color Steel Solar Mounting Structure Roll Forming Machine is designed to efficiently produce high-quality solar mounting structures using color steel. This machine is equipped with advanced technology that allows for precision roll forming, resulting in perfectly shaped and durable solar mounting structures. Its high-speed production capabilities make it an ideal choice for companies looking to streamline their manufacturing process and increase productivity.One of the key features of this machine is its versatility. It can be customized to produce different types and sizes of solar mounting structures, allowing for greater flexibility in manufacturing. This versatility also makes it an attractive option for companies looking to expand their product offerings or enter new market segments.In addition to its advanced technology and versatility, the Color Steel Solar Mounting Structure Roll Forming Machine is also known for its durability and reliability. It is built to withstand the rigors of continuous operation, ensuring consistent and high-quality output. This reliability is essential for companies looking to meet the demands of a rapidly growing solar industry.[Company Name] has been a leader in the manufacturing of roll forming machines for [number] years. The company has built a reputation for producing high-quality, innovative machines that meet the evolving needs of the industry. Its team of engineers and designers are constantly pushing the boundaries of technology to develop cutting-edge machines that deliver exceptional performance and efficiency.The Color Steel Solar Mounting Structure Roll Forming Machine is the latest addition to [Company Name]'s impressive lineup of roll forming machines. It represents the company's commitment to staying at the forefront of industry trends and providing its customers with the tools they need to succeed in a competitive market.This machine has already garnered attention from companies looking to invest in state-of-the-art equipment to improve their manufacturing processes. Its ability to produce high-quality solar mounting structures at a rapid pace makes it an attractive option for companies looking to scale up their operations and meet the growing demand for renewable energy solutions.The Color Steel Solar Mounting Structure Roll Forming Machine has the potential to revolutionize the way solar mounting structures are manufactured. Its advanced technology, versatility, durability, and reliability make it an ideal choice for companies looking to stay ahead of the curve in the rapidly expanding solar industry.With [Company Name]'s track record of excellence and innovation, the Color Steel Solar Mounting Structure Roll Forming Machine is poised to become a game-changer in the industry. As more companies embrace renewable energy solutions, this machine will play a crucial role in meeting the demand for high-quality solar mounting structures.In conclusion, the Color Steel Solar Mounting Structure Roll Forming Machine is a testament to [Company Name]'s commitment to excellence and innovation. Its advanced technology, versatility, durability, and reliability make it a game-changing addition to the industry. As the demand for renewable energy solutions continues to grow, this machine will undoubtedly play a crucial role in meeting the needs of companies looking to expand their manufacturing capabilities.

Color Steel Roll Forming Machine for Single Layer Steel Sheets: What You Need to Know

Single Layer Color Steel Roll Forming Machine Revolutionizing the IndustryIn an industry where efficiency and productivity are essential, the {Company Name} has introduced a game-changing innovation with their Single Layer Color Steel Roll Forming Machine. This state-of-the-art equipment is revolutionizing the way steel roofing and cladding products are manufactured, setting a new standard for speed, precision, and quality.The Single Layer Color Steel Roll Forming Machine is designed to streamline the production process, allowing for seamless and efficient manufacturing of color steel roofing and cladding products. With its advanced technology and automated features, this machine has significantly reduced production time, minimized material waste, and improved overall product quality.The innovative design of the Single Layer Color Steel Roll Forming Machine has been welcomed by industry professionals as a game-changer. Its ability to produce high-quality color steel products with unparalleled accuracy and consistency has set a new benchmark for the industry. Additionally, its customizable features allow for a wide range of product specifications, catering to the diverse needs of customers.The {Company Name} is known for its commitment to excellence and continuous innovation. With a strong focus on research and development, the company has always been at the forefront of technological advancements in the steel manufacturing industry. The introduction of the Single Layer Color Steel Roll Forming Machine is a testament to their dedication to providing cutting-edge solutions to their customers.In addition to its superior performance, the Single Layer Color Steel Roll Forming Machine also offers environmental benefits. Its efficient use of materials and energy-saving features contribute to a more sustainable manufacturing process. As the industry continues to prioritize environmental responsibility, this machine aligns with the growing demand for eco-friendly production methods.Furthermore, the Single Layer Color Steel Roll Forming Machine has been designed with user-friendly features, making it easy to operate and maintain. This has resulted in increased productivity and reduced downtime for manufacturers, ultimately leading to cost savings and improved operational efficiency.With its impressive capabilities and numerous benefits, the Single Layer Color Steel Roll Forming Machine has already made a significant impact on the industry. Manufacturers who have adopted this technology have reported increased production capacity, improved product quality, and reduced manufacturing costs. This has also led to enhanced competitiveness in the market, positioning them as leaders in the industry.The launch of the Single Layer Color Steel Roll Forming Machine has generated excitement and anticipation within the industry. Its potential to transform the way color steel products are manufactured has captured the attention of manufacturers worldwide. As the demand for high-quality, efficient production solutions continues to grow, the innovative features of this machine are expected to reshape the industry landscape.In conclusion, the {Company Name} has once again demonstrated its leadership in the steel manufacturing industry with the introduction of the Single Layer Color Steel Roll Forming Machine. This technologically advanced equipment is setting a new standard for efficiency, precision, and quality in the production of color steel roofing and cladding products. As manufacturers increasingly seek innovative solutions to improve their production processes, the Single Layer Color Steel Roll Forming Machine stands out as a game-changing innovation that is driving the industry forward.