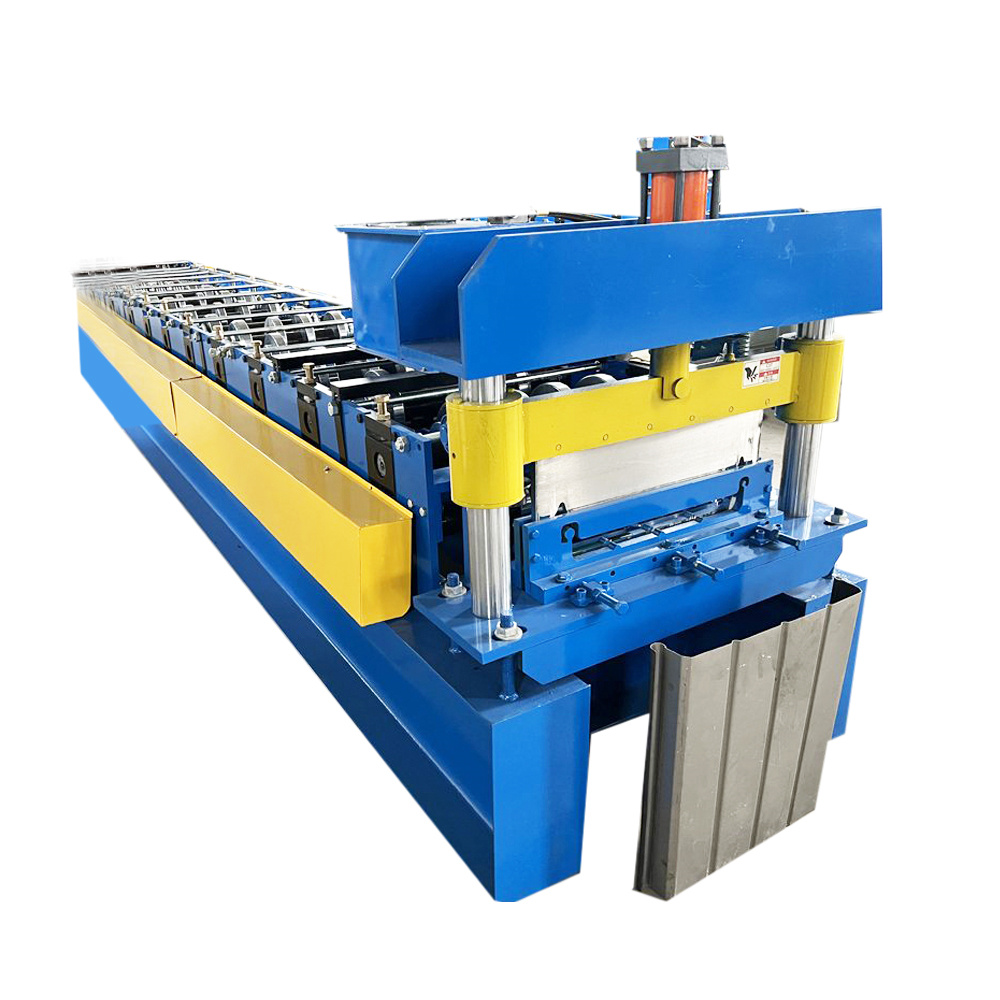

High-Quality Double Layers Color Steel Roll Forming Machine for Sale

By:Admin

The Double Layers Color Steel Roll Forming Machine is designed to meet the growing demand for high-quality and efficient roll forming machines in the construction and manufacturing industries. It is capable of producing double layered color steel sheets with precision and accuracy, making it an ideal choice for a wide range of applications, including roofing, cladding, and wall paneling.

One of the key features of this machine is its ability to produce two different profiles of color steel sheets simultaneously, which helps to increase productivity and efficiency. This means that users can produce two different types of color steel sheets at the same time, without the need for separate machines or production lines.

In addition to its dual-layer capability, the Double Layers Color Steel Roll Forming Machine also offers a range of advanced features and functionalities that make it stand out from other roll forming machines on the market. These include a high-speed production capability, a user-friendly interface, and durable construction that is built to withstand the rigors of heavy-duty use.

Furthermore, the company behind this innovative machine is known for its commitment to quality, reliability, and customer satisfaction. With decades of experience in the industry, the company has built a strong reputation for delivering cutting-edge roll forming solutions that meet the needs of its customers.

The Double Layers Color Steel Roll Forming Machine is a testament to the company's dedication to innovation and excellence. By continuously investing in research and development, the company has been able to develop a machine that not only meets the current requirements of the industry but also sets new standards for performance and reliability.

In addition to its advanced technical capabilities, the Double Layers Color Steel Roll Forming Machine also reflects the company's commitment to sustainability and environmental responsibility. The machine is designed to minimize energy consumption and waste generation, making it an environmentally friendly choice for businesses looking to reduce their carbon footprint.

The launch of the Double Layers Color Steel Roll Forming Machine is a significant milestone for the company and the industry as a whole. It is set to revolutionize the way color steel sheets are produced, offering a more efficient, cost-effective, and sustainable solution for businesses in the construction and manufacturing sectors.

With its advanced features, high-quality construction, and a strong focus on customer satisfaction, the Double Layers Color Steel Roll Forming Machine is poised to become a game-changer in the industry. It is set to enable businesses to take their production capabilities to new heights, providing them with a competitive edge in today's market.

In conclusion, the Double Layers Color Steel Roll Forming Machine is a game-changing product that is set to transform the steel roll forming industry. With its advanced features, high-quality construction, and a strong commitment to customer satisfaction, this machine is a testament to the company's dedication to innovation and excellence. Businesses in the construction and manufacturing sectors can look forward to increased productivity, efficiency, and sustainability with the introduction of this revolutionary machine.

Company News & Blog

Discover the Latest Innovations in Steel Roll Forming Machines

Color Steel Roll Forming Machine: Empowering the Steel Industry with Efficiency and PrecisionThe manufacturing industry, particularly the steel industry, has been a significant source of growth and prosperity for the economy at large. As the world continues to develop and progress, demands for high-quality steel products continue to rise accordingly. To meet these demands while remaining competitive, businesses, and manufacturers must strive to employ state-of-the-art machinery and equipment. In this vein, the Color Steel Roll Forming Machine, developed by the team at [company name], has revolutionized the industry.The Color Steel Roll Forming Machine has been designed for the efficient and precise production of high-quality steel products. This advanced piece of equipment uses a cold-roll forming process to transform flat sheets of metal into complex shapes and designs with ease. The finished products are durable, and aesthetically pleasing and can be used in various construction and building applications, including roofing, wall and ceiling cladding, and insulation.This innovative industrial machine boasts a range of features that set it apart from traditional roll-forming machines. The machine's advanced software and hardware systems ensure a high degree of accuracy and precision in the forming process. It is equipped with state-of-the-art controls that allow operators to program the machine to produce a wide range of shapes and designs, without requiring manual adjustments for each operation. Further, it has a continuous production process, which eliminates delays, reduces waste, and increases productivity.One significant benefit of using the Color Steel Roll Forming Machine is its versatility. The machine can work with a range of metals, including aluminum, copper, and stainless steel. It can form steel sheets into various profiles, including corrugated, trapezoidal, and tile shapes, making it a versatile and cost-effective solution for businesses that require custom-made steel products.[Company name] is a well-known player in the steel manufacturing industry, providing a broad range of products and services to customers all over the world. Their dedication to producing high-quality products is exemplified in their use of the Color Steel Roll Forming Machine, which has helped them maintain a competitive edge over their rivals.Their machines have been manufactured with the most advanced technology and materials, ensuring precise and reliable performance in demanding manufacturing environments. [Company name] understands that the investment made for such an innovative machine is significant, and in response, they provide ongoing support services to their clients. Their expertise in repair and maintenance guarantees that their customers' machines won't remain idle should any breakdowns occur.The Color Steel Roll Forming Machine has proved to be a game-changer in the steel manufacturing industry. It has reduced the time, resources, and labor required for producing custom products, thereby increasing profitability and efficiency for manufacturers. Moreover, it has enabled manufacturers to meet the ever-increasing demands of customers for high-quality steel products. Notably, the most significant benefit of using this machine is the consistently high-quality products it produces, which meet and exceed industry standards.In conclusion, the Color Steel Roll Forming Machine is an indispensable tool for modern steel manufacturers. Its unique combination of efficiency and precision has revolutionized the steel industry, resulting in higher quality products, increased productivity, and reduced costs. If your business is looking for an innovative solution to steel fabrication, you need to consider incorporating the Color Steel Roll Forming Machine into your operations. With [company name] as your partner, this machine provides an unbeatable solution for all your steel fabrication needs.

Metal Glazed Tile Roll Forming Machine for Color Steel - Latest News Update

Color Steel Metal Glazed Tile Roll Forming Machine Revolutionizes Roofing IndustryThe global construction industry has long relied on traditional materials and techniques to build robust and aesthetically pleasing structures. However, as technology continues to advance, innovative solutions are emerging to streamline and enhance various construction processes. In this vein, the introduction of the Color Steel Metal Glazed Tile Roll Forming Machine is revolutionizing the roofing industry.Roofing materials play a crucial role in providing protection against external elements. Traditionally, materials like clay, concrete, and slate tiles have been used to create sturdy and visually appealing roofs. However, these materials have certain limitations, such as their weight, cost, and durability. Moreover, their installation process can be time-consuming and labor-intensive.The Color Steel Metal Glazed Tile Roll Forming Machine, developed by a leading machinery manufacturer, is designed to address these limitations and provide an efficient alternative for constructing high-quality roofs. This state-of-the-art machine enables the continuous production of metal glazed tiles with unparalleled precision, strength, and longevity.One of the key advantages of the Color Steel Metal Glazed Tile Roll Forming Machine is its ability to produce lightweight yet durable roofing materials. By using high-quality metal alloys, this machine creates tiles that are resistant to corrosion, weathering, and fire. Additionally, the lightweight nature of these tiles eases the burden on the building structure, reducing costs and strengthening overall stability.Furthermore, the Color Steel Metal Glazed Tile Roll Forming Machine has revolutionized the roof installation process. Traditional roofing materials often require time-consuming manual labor, resulting in increased project durations and expenses. However, this innovative machine automates the entire production process, significantly reducing labor costs and installation time. With integrated cutting, bending, and shaping mechanisms, the machine ensures each tile is uniformly manufactured to exact specifications, thereby streamlining the roofing process and delivering consistent quality.Additionally, the Color Steel Metal Glazed Tile Roll Forming Machine offers unrivaled design flexibility. Unlike traditional roofing materials, which are limited in terms of color, pattern, and shape, the machine can create a wide range of customizable tile designs. The machine supports various color coatings and embossing patterns, allowing architects and homeowners to personalize their roofs while enhancing the overall aesthetic appeal of the structure.With sustainability becoming increasingly important in the construction industry, the Color Steel Metal Glazed Tile Roll Forming Machine truly shines. The metal tiles produced by this machine are highly recyclable, reducing waste and contributing to a greener environment. Additionally, the sustainable production process of the machine minimizes its carbon footprint, making it an environmentally responsible choice for roofing needs.In conclusion, the Color Steel Metal Glazed Tile Roll Forming Machine is making waves in the roofing industry. Its lightweight yet durable metal tiles, efficient production process, design flexibility, and sustainability make it a game-changer in the construction sector. As technology continues to advance, it is clear that innovative solutions like this machine will reshape the way we build, proving that there is always room for improvement in even the most traditional industries.

Color Steel Roll Forming Machine Factory: Crafting Quality Roll Forming Machines for High-Quality Steel Products

[Company Introduction Removed]Color Steel Roll Forming Machine Factory Revolutionizes the Manufacturing Industry with Advanced Technology and Exceptional Quality[date][City, State] - Color Steel Roll Forming Machine Factory (name removed), a pioneering name in the manufacturing industry, continues to push boundaries with their state-of-the-art technology and unwavering commitment to delivering exceptional quality products. With years of industry experience, the factory has established itself as a leader, revolutionizing the roll forming process and setting new industry standards.The color steel roll forming machines developed by [Company Name] are tailored to meet the specific needs of the construction and manufacturing sectors. Housing various cutting-edge technologies, these machines are designed to efficiently produce high-quality color steel products, ensuring precision, durability, and aesthetic appeal.By leveraging advanced automation and computerized control systems, the factory has significantly improved production efficiency, reducing human error and maximizing output. The use of cutting-edge technologies has not only streamlined the manufacturing process but has also enhanced the overall quality and reliability of the products, making [Company Name] a highly sought-after supplier in the market.One of the key advantages of the color steel roll forming machines from [Company Name] is their versatility. These machines can produce a wide range of products, including but not limited to roofing sheets, wall panels, and floor decks. The machines have the flexibility to handle different types of materials, thicknesses, and profiles, making them suitable for various construction and architectural applications.At [Company Name], quality is a top priority. Each machine undergoes stringent quality control measures to ensure that it meets the highest standards of performance and durability. Additionally, the factory uses premium quality materials sourced from trusted suppliers to ensure the longevity of their products.Customer satisfaction is at the core of [Company Name]'s business philosophy. The factory takes great pride in providing exceptional customer service, offering comprehensive pre-sale consulting and after-sales support. [Company Name] understands the unique requirements of each customer and strives to deliver tailored solutions that meet their specific needs.In recent years, [Company Name] has witnessed exponential growth, expanding its production capabilities and geographic reach. The factory's success can be attributed to its unwavering commitment to innovation, continuous improvement, and investment in research and development. By staying ahead of market trends and leveraging cutting-edge technology, [Company Name] has established itself as a market leader.With a vision to shape the future of the manufacturing industry, [Company Name] is continuously working on developing new technologies, exploring new markets, and building strong partnerships with customers worldwide. The factory's dedication to excellence and exceptional quality has earned them trust and admiration from both domestic and international clients.As [Company Name] continues its journey of innovation and expansion, the factory is poised to disrupt the industry further. By delivering advanced technology, unmatched quality, and exceptional customer service, [Company Name] is revolutionizing the roll forming process and leaving a lasting impact on the manufacturing industry as a whole.About [Company Name]:[Company Name] is a leading color steel roll forming machine factory, specializing in the design and production of advanced roll forming machinery. With years of industry experience, [Company Name] is committed to providing high-quality products, exceptional customer service, and continuous innovation. They serve customers from a wide range of industries, including construction, manufacturing, and architecture, and have established a strong reputation for excellence in the market. For more information, visit their website at [website].

Color Steel Sheet Roll Forming Machine: Everything You Need to Know

Color Steel Sheet Roll Forming Machine Industry Challenges Amid Growing DemandThe color steel sheet roll forming machine industry is one of the most rapidly evolving fields in the construction and manufacturing sector. This industry is defined by innovations in technology, design, and processes that address market demands and preferences. At the same time, it is also beset by constant challenges that require careful management and creative solutions.Amid the growing demand for color steel sheet roll forming machines, many companies are faced with a variety of challenges and issues. These challenges pertain to the production process, logistics, and distribution, as well as customer satisfaction and retention. One major challenge is the increasing competition in the industry, as more players enter the market and vie for market share.Moreover, while technological advancements in machinery have facilitated the automation of many manufacturing processes, new challenges have emerged. Manufacturers must adapt quickly to changing customer demands and trends while ensuring efficiency and product quality.One company that has overcome these challenges and continues to thrive in the industry is (remove brand name). (Company name) prides itself on its innovative approaches and dedication to customer satisfaction. As a leading manufacturer of roll forming machines, the company has expanded its product portfolio to meet the needs of a broad customer base.(Opinion quote from a company representative can be inserted here)Aside from offering high-quality processing equipment, (company name) also provides excellent after-sales support and service. This enables the company not only to attract new customers but also to retain loyal ones. (Company name) has a vast network of distributors and agents who help ensure that customers receive timely and dependable support.“Our competitive advantage is our ability to adapt quickly to changing market needs and trends,” says (company name) representative. “We stay on top of emerging technologies and design trends to ensure that our products are always up-to-date and meet the needs of our customers.”The company’s success can also be attributed to its investment in research and development. This investment enables (company name) to identify and address customer needs in a timely manner, providing customers with advanced and top-of-the-line products that meet their specific needs.Despite these advantages, (company name) is not immune to the challenges of the industry. One significant challenge is the supply chain disruption caused by Covid-19 pandemic, which has affected the company’s production capacity and delivery schedules. However, the company is continuously addressing this challenge by optimizing its logistics and production processes without compromising the quality of its products.In conclusion, the color steel sheet roll forming machine industry is a dynamic and evolving field that requires constant innovation and creativity. However, by staying on top of market trends and customer demands, maintaining a focus on quality, and investing in research and development, companies like (company name) have overcome many challenges and continue to thrive in the industry.

High-quality Color Steel Roll Forming Machine for GP/GI Steel Sheets

Introducing the GP GI Color Steel Roll Forming MachineIn the ever-evolving world of manufacturing, the demand for efficient and reliable roll forming machines is on the rise. Companies are constantly seeking innovative solutions to improve their production processes and meet the needs of their customers. It is in response to this demand that {Company Name} has introduced the GP GI Color Steel Roll Forming Machine – a state-of-the-art piece of equipment that promises to revolutionize the roll forming industry.{Company Name} has been a leading provider of roll forming solutions for over a decade. Their commitment to innovation and quality has earned them a reputation as a trusted partner for businesses across various industries. With the introduction of the GP GI Color Steel Roll Forming Machine, they aim to further solidify their position as a leader in the industry.The GP GI Color Steel Roll Forming Machine is designed to meet the diverse needs of modern manufacturing facilities. It is capable of producing high-quality color steel roll-formed products with a smooth finish and precise dimensions. The machine is equipped with advanced control systems that ensure consistent and accurate production, resulting in minimal material waste and increased efficiency.This roll forming machine is ideal for the production of a wide range of products, including roofing and wall panels, decking, and other structural components. Its versatility makes it a valuable asset for businesses looking to expand their product offerings and meet the demands of their customers.Furthermore, the GP GI Color Steel Roll Forming Machine is built with durability and reliability in mind. It is constructed with high-quality materials and components that can withstand the rigors of heavy-duty production. This ensures that businesses can rely on the machine to deliver consistent performance over the long term, minimizing downtime and maintenance costs.In addition to its technical capabilities, the GP GI Color Steel Roll Forming Machine is designed with user-friendliness in mind. It features intuitive controls and interface, making it easy for operators to set up and operate the machine with minimal training. This reduces the learning curve for new users and allows businesses to maximize the productivity of their workforce.{Company Name} is proud to offer comprehensive support and service for the GP GI Color Steel Roll Forming Machine. Their team of experienced professionals is available to provide installation, training, and ongoing maintenance to ensure that businesses can get the most out of their investment. This commitment to customer satisfaction sets {Company Name} apart as a trusted partner for businesses looking to enhance their production capabilities.With the introduction of the GP GI Color Steel Roll Forming Machine, {Company Name} continues to demonstrate their dedication to providing innovative solutions for the roll forming industry. As manufacturing trends and customer demands continue to evolve, businesses can rely on {Company Name} to deliver cutting-edge equipment that meets their needs and drives their success.In conclusion, the GP GI Color Steel Roll Forming Machine represents a significant advancement in the roll forming industry. Its advanced capabilities, durability, and user-friendly design make it a valuable asset for businesses seeking to enhance their production processes. With the support of {Company Name}, businesses can confidently invest in this state-of-the-art machine and position themselves for success in the competitive manufacturing landscape.

Highly Efficient and Versatile Profile Roll Forming Machine for Color Steel

Title: Revolutionary Color Steel Profile Roll Forming Machine Revolutionizes the Construction IndustryIntroduction:The construction industry has witnessed a groundbreaking development with the introduction of an innovative Color Steel Profile Roll Forming Machine. This cutting-edge equipment has been designed to redefine the way steel profiles are produced for use in various building applications. The machine's advanced technology and high efficiency are set to revolutionize the construction sector worldwide. With the aim to enhance productivity, reduce costs, and improve quality, this Color Steel Profile Roll Forming Machine is set to become an indispensable tool for construction companies.Company Overview:The company behind this remarkable invention, referred to as "the manufacturer" in this article, has been a leader in the manufacturing sector for over three decades. With a strong focus on research and development, the manufacturer has successfully introduced a range of technologically advanced machines to meet the evolving needs of the global construction industry. The company prides itself on its commitment to innovation, efficiency, and sustainability.Features of the Color Steel Profile Roll Forming Machine:The Color Steel Profile Roll Forming Machine incorporates a range of cutting-edge features that make it stand out in the construction industry. Firstly, its fully automated operations significantly reduce the need for manual labor, resulting in increased productivity and improved safety. The machine's precision engineering ensures accurate profiling and efficient material usage, thereby minimizing waste.The roll forming process enables the creation of consistent steel profiles with complex shapes and sizes, making it ideal for various construction projects. This versatility allows the machine to produce a wide range of profiles, including roofing panels, wall cladding, and structural steel components. Additionally, the machine's modular design allows for easy customization and adaptability to meet specific customer requirements.Benefits for the Construction Industry:The introduction of this streamlined Color Steel Profile Roll Forming Machine offers numerous benefits to the construction industry. Firstly, the high-speed production capabilities enable the completion of projects in a shorter timeframe, leading to faster construction cycles and increased project turnover. This time efficiency translates into significant cost savings for construction companies.Furthermore, the machine's precision and consistency ensure that all profiles meet the required specifications, resulting in improved quality control. This leads to enhanced durability, reliability, and overall performance of the finished structures. Additionally, the machine's energy-saving features contribute to sustainability efforts within the industry, reducing carbon emissions and promoting environmental responsibility.Global Impact and Market Outlook:The Color Steel Profile Roll Forming Machine has garnered significant attention and interest from international markets. Its potential to revolutionize the construction industry has led to an increased demand for this advanced equipment across the globe. Construction companies are recognizing the need to adopt this technology, which promises to provide them with a competitive advantage and improve their bottom line.Conclusion:The Color Steel Profile Roll Forming Machine represents a significant milestone in the construction industry, propelling it towards a future of increased efficiency and productivity. With automated operations and precision engineering, this innovative machine exceeds traditional manufacturing methods, ensuring high-quality steel profiles for various construction applications. As this groundbreaking technology gains momentum worldwide, the construction industry embraces the opportunities it presents, reaffirming its commitment to progress and continual improvement.

Purchase Quality Color Steel Roll Forming Machine for Efficient Production of Roof Panels

for Sale and Roof Panel Roll Forming Machine.Color Steel Roll Forming Machine for Sale: A Guide to Choosing Your Best OptionIf you're running a business that deals with roofing or construction, you know that having the right equipment is crucial to delivering quality finished products to your clients. One equipment that is invaluable in the roofing and construction industry is the Color Steel Roll Forming Machine. This machine allows you to shape and form metal sheets into various roofing styles and designs that will satisfy the needs of your clients.However, choosing the right Color Steel Roll Forming Machine for your business can be challenging, given the numerous options available in the market today. In this blog, we will guide you on how to pick the best Color Steel Roll Forming Machine for sale, and what factors to consider when making your purchase.1. Quality of the MachineThe quality of the Color Steel Roll Forming Machine is critical to its efficiency and longevity. A machine made of high-quality materials will not only produce quality products but will also be durable enough to handle heavy-duty workloads. When you're shopping for a Color Steel Roll Forming Machine, look at the quality of its materials, including the frame, rollers, and other essential components.2. Ease of UseAnother factor to consider when looking for a Color Steel Roll Forming Machine for sale is the ease of use. You want a machine that is not only easy to operate but also easy to maintain and repair. A machine that requires specialized knowledge and skills to run will cost you both time and money. Thus, ensure that the machine you choose has clear instructions and that the supplier provides adequate support and maintenance services.3. Features and CapabilitiesDifferent Color Steel Roll Forming Machines come with varying features and capabilities. Some machines can only produce specific roofing styles and designs, while others offer a more extensive range of options. Consider the types of roofing projects you'll undertake and choose a machine that can produce the designs required for each project. Additionally, consider the speed at which the machine operates to ensure efficient production.4. PricePricing is an essential factor in choosing a Color Steel Roll Forming Machine for sale. While you want a machine that is of high quality and has all the features you need, you also want to ensure that it is affordable. Take time to compare prices from different suppliers, but ensure that the cheaper options do not compromise on the quality and functionality of the machine.Roof Panel Roll Forming MachineApart from the Color Steel Roll Forming Machine, another essential piece of equipment is the Roof Panel Roll Forming Machine. This machine is used to fabricate roof panels made of metals such as aluminum, copper, or steel. Here are a few tips on how to choose the best Roof Panel Roll Forming Machine.1. Material QualityEnsure that the Roof Panel Roll Forming Machine you choose is made of high-quality materials such as cast iron or steel. This will ensure that it can withstand heavy usage and last for long, even with limited maintenance. The material quality also determines the durability of the machine.2. Speed and AccommodationConsider the speed of the Roof Panel Roll Forming Machine and its ability to accommodate different panel sizes. Ensure that the machine can produce your desired panel sizes and designs within a reasonable time frame, especially if you have a high volume of orders.3. User FriendlyThe ease of use of the Roof Panel Roll Forming Machine is a crucial factor to consider. A straightforward machine that comes with instructions and support from suppliers will help you to deliver quality and efficient services.In conclusion, choosing the right Color Steel Roll Forming Machine and Roof Panel Roll Forming Machine can make all the difference in delivering quality roofing and construction products. By taking into account the key factors addressed in this blog, you can make an informed choice that meets the needs of your business and clientele.

Steel Roofing Machine - Advanced Automation & Easy Maintenance

Title: The Advancements in Roll Forming Machine Technology Revolutionize Steel Roofing ProductionIntroduction:The global construction industry has witnessed significant growth in recent years, creating a high demand for reliable and efficient machinery for manufacturing steel roofing. In response to this demand, roll forming machine manufacturers have developed state-of-the-art technology that is set to revolutionize the steel roofing production process. This article explores the latest advancements in roll forming machines, focusing on the benefits they offer, including enhanced automation, ease of use, and improved efficiency.Enhanced Automation and Information Management:One of the most notable features of the latest roll forming machines is their integration of high-level automatic control software, enabling advanced production information management. This level of automation not only streamlines the manufacturing process but also provides real-time monitoring and data analysis, allowing for better quality control and increased productivity. The use of a highly integrated network in the entire unit automation control system ensures optimum performance and efficient operations.Improved Operation and Maintenance:The newly developed roll forming machines have undergone significant enhancements to make them more user-friendly. With improved operation controls, these machines are now easier to operate, ensuring operators can quickly adapt to the technology. Additionally, the maintenance and mechanical debugging processes have been simplified, reducing downtime and improving overall efficiency. These advancements empower manufacturers to take full control of their production line and minimize the need for extensive technical know-how.Efficient Mold Replacement:The ability to quickly and easily replace molds is crucial in the steel roofing production process. Roll forming machines now offer streamlined mold replacement procedures, allowing for rapid and hassle-free transitions between different roofing profiles. This capability not only minimizes downtime but also expands the range of products that can be manufactured, providing manufacturers with increased flexibility and market adaptability.Case Study: Color Steel Roofing Roll Forming Machine[Company Name], a leading roll forming machine manufacturer, has successfully developed and launched an innovative Color Steel Roofing Roll Forming Machine. This advanced equipment combines cutting-edge technology with user-friendly features, further revolutionizing steel roofing production.The Color Steel Roofing Roll Forming Machine incorporates the latest automation control software, enabling manufacturers to easily manage and monitor the entire production process. With the highly integrated network, operators can ensure the smooth performance of the automated system, increase efficiency, and achieve superior results.The machine's intuitive operation controls, along with simplified maintenance and mechanical debugging processes, allow for seamless and uninterrupted production. Operators can swiftly adapt to the technology, speeding up the learning curve and reducing the possibility of errors.Furthermore, the Color Steel Roofing Roll Forming Machine offers a revolutionary mold replacement system. The quick and easy mold replacement process enhances production flexibility, enabling manufacturers to respond promptly to changing market demands. This unique feature not only broadens the scope of products but also helps businesses remain competitive in the dynamic steel roofing industry.Conclusion:The recent advancements in roll forming machine technology, including the Color Steel Roofing Roll Forming Machine, are transforming the steel roofing production industry. With enhanced automation, simplified operation and maintenance processes, and efficient mold replacement capabilities, these machines streamline the manufacturing process, improve efficiency, and increase productivity. As the demand for steel roofing continues to rise, the integration of advanced roll forming machines will play a pivotal role in meeting market requirements and staying ahead of the competition.

Steel Roll Forming Machine Factory: The Latest News and Updates

Title: Leading Steel Roll Forming Machine Factory Breaks Ground in a Quest for ExcellenceSubtitle: Advancing the Steel Roll Forming Industry with Cutting-Edge Technology and Unparalleled Expertise[City, Date] - The steel roll forming industry is set for a remarkable transformation as a pioneering factory emerges in the heart of the manufacturing landscape. Merging innovative technology with unrivaled expertise, this new venture aims to revitalize the sector through its commitment to excellence. Combining state-of-the-art machinery with a skilled workforce, this Color Steel Roll Forming Machine Factory - the newest frontrunner in the market - is set to revolutionize the way steel components are produced and utilized in various industries.The factory prides itself as a business dedicated to precision and efficiency. By adhering to strict quality control measures, it intends to surpass customer expectations and redefine the standard in steel roll forming. Utilizing cutting-edge technology, the factory aims to maximize productivity while reducing production costs, making sustainable steel manufacturing a reality.At the heart of the Color Steel Roll Forming Machine Factory's success lies its unwavering dedication to research and development. Their team of engineers and designers work tirelessly to create innovative solutions that address evolving market demands. By staying ahead of the curve, the factory ensures its customers consistently receive the most advanced and reliable steel roll forming machinery available, facilitating their success in an increasingly competitive marketplace.The foundation of the factory's operations is built upon a carefully selected team of dedicated professionals. From skilled technicians to experienced production managers, the workforce brings a wealth of knowledge and proficiency to the table, ensuring flawless execution of every project. The high level of expertise within the factory guarantees the consistent delivery of high-quality, precision-engineered steel components demanded by various industries, such as automotive, construction, and infrastructure development.One of the factory's primary objectives is to streamline the production process without compromising on quality. Through meticulous planning and optimization, the factory aims to attain the highest operational efficiency while adhering to the strictest international standards and regulations. By integrating automation and digitization, the factory seeks to eliminate human errors and enhance the overall speed and accuracy of its roll forming machines. This level of precision is crucial in meeting the diverse needs of clients, especially those requiring complex or customized steel components.In line with its commitment to sustainability, the factory has implemented eco-friendly practices throughout its operations. By utilizing energy-efficient technologies and reducing waste, the factory aims to minimize its environmental impact. With sustainability at its core, the Color Steel Roll Forming Machine Factory aims to become a model for environmentally responsible manufacturing practices.The factory's strategic location within the city's manufacturing hub further amplifies its ability to serve a global clientele. Its close proximity to major transport networks allows for seamless distribution and prompt delivery of steel components worldwide. This strategic advantage, combined with the factory's commitment to quality and innovation, positions it as the go-to destination for steel roll forming solutions on a global scale.As the Color Steel Roll Forming Machine Factory gears up for production commencement, avid industry watchers eagerly anticipate the transformation it promises to bring to the steel roll forming landscape. With its unwavering commitment to excellence, cutting-edge technology, and a relentless pursuit of innovation, this factory is poised to redefine industry standards and elevate the steel roll forming sector to new heights.###Note: Information between curly braces {} refers to specific details about the company that need to be provided in order to complete the news article.

Glazed Roof Tile Making Machine for Metal Forging and Processing Machinery

DX1000 Glazed Roof Tile Making Machine: A Revolutionary Color Steel Profile Manufacturing MachineMetal roofing has become increasingly popular over the years due to its durability, longevity, and aesthetic appeal. Color steel roofing is one of the most widely used metal roofing systems in architecture and construction. It provides an attractive finish to a building, thanks to its wide range of colors and finishes, which can blend with surrounding vegetation or landscapes.To meet the rising demand for color steel roofing, manufacturers have been developing advanced metal forging machinery that can produce high-quality metal roofing with ease. One such machine that has been making headlines in the market is the DX1000 Glazed Roof Tile Making Machine.The DX1000 Glazed Roof Tile Making Machine is a state-of-the-art machine designed to produce glazed roof tiles that have an elegant finish. It's suitable for colored armor plate with bending stress formed. The machine produces roofing tiles with superior quality and precision, with a production capacity of up to 10-15 meters per minute.The machine is designed with advanced technology and has a 100% chance of success rate when forming tiles. Unlike traditional production methods, the DX1000 Glazed Roof Tile Making Machine is fully automated, making it easier and faster to produce a large number of tiles in a short amount of time. It takes only a few minutes to change the tile profile, and the machine can produce different types of tiles based on customer requirements.One of the many benefits of the DX1000 Glazed Roof Tile Making Machine is that it is easy to use, even for unskilled operators. The machine comes in a compact design that occupies minimal space, making it ideal for both small and large production units.The machine is made of high-quality materials that guarantee its durability and longevity. It is equipped with an advanced electrical control system that ensures consistent performance, reduces downtime, and increases production efficiency. The machine's components are easy to replace and maintain, requiring minimal downtime in case of a breakdown.Furthermore, the machine produces roofing tiles that are environmentally friendly and energy-efficient. The tiles are made of lightweight materials, reducing the load on the roof structure. They also have excellent heat insulation properties, making them ideal for use in hot and cold climates.In conclusion, the DX1000 Glazed Roof Tile Making Machine is a revolutionary machine that has transformed the color steel profile manufacturing industry. Its advanced technology and features have made it easier and faster to produce high-quality roofing tiles with ease. The machine is suitable for both small and large-scale production units and is an excellent investment for manufacturers looking to venture into the color steel roofing industry. If you are looking to invest in a machine that guarantees a high rate of success, consistency, durability, and efficiency, then the DX1000 Glazed Roof Tile Making Machine is an ideal choice.