High-Quality Profile Roll Forming Machine for Color Steel

By:Admin

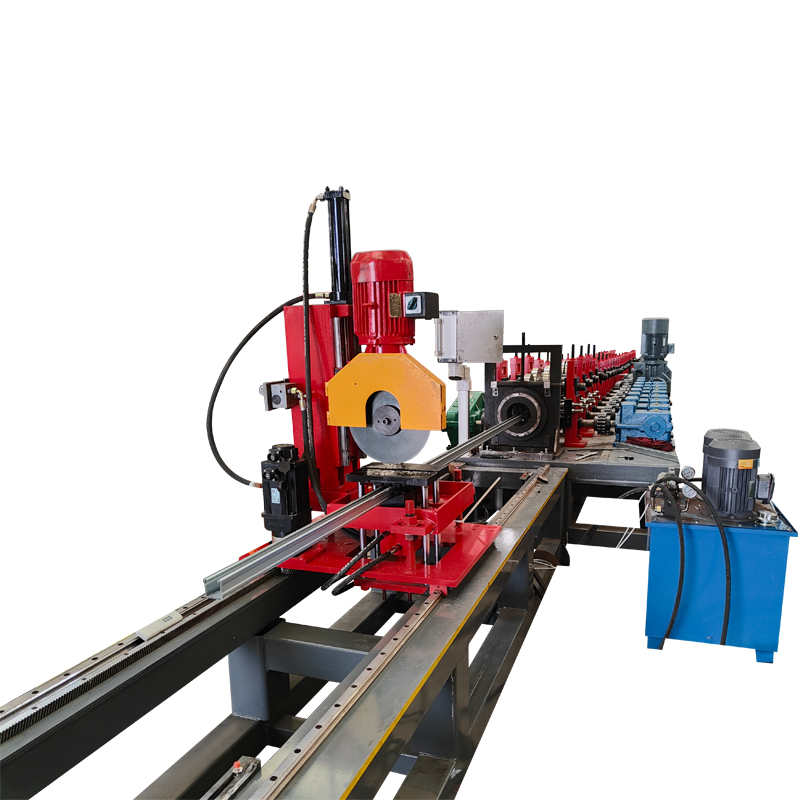

The latest Color Steel Profile Roll Forming Machine from [Company Name] has taken the construction industry by storm, revolutionizing the way in which steel profiles are manufactured and used in building projects. This state-of-the-art machine is set to have a significant impact on the construction industry, offering unparalleled precision, efficiency, and versatility in the production of color steel profiles.

With a focus on innovation and cutting-edge technology, [Company Name] has been at the forefront of developing advanced machinery for the construction sector. The Color Steel Profile Roll Forming Machine is a testament to the company's commitment to providing innovative solutions that enhance the efficiency and quality of construction projects.

The Color Steel Profile Roll Forming Machine is designed to meet the growing demand for high-quality and customized steel profiles in the construction industry. It is capable of producing a wide range of profiles, including roofing panels, wall panels, and other structural components, with exceptional accuracy and consistency. This level of precision is essential for ensuring the structural integrity and aesthetic appeal of modern buildings.

One of the key features of the Color Steel Profile Roll Forming Machine is its ability to streamline the production process, significantly reducing the time and labor required to manufacture steel profiles. This not only increases efficiency but also minimizes production costs, making it an attractive investment for construction companies looking to optimize their operations.

In addition to its efficiency, the Color Steel Profile Roll Forming Machine offers unparalleled versatility, allowing for the customization of steel profiles to meet the specific needs of each project. This capability is essential for architects and builders who seek to create unique and innovative designs, as it provides the flexibility to produce custom profiles with different shapes, sizes, and finishes.

The introduction of the Color Steel Profile Roll Forming Machine is expected to have a transformative impact on the construction industry, as it sets a new standard for the production of steel profiles. Its advanced technology and superior performance have already garnered widespread attention and enthusiasm from industry professionals, who recognize its potential to drive innovation and improve the quality of construction projects.

In addition to its technical capabilities, the Color Steel Profile Roll Forming Machine reflects [Company Name]'s commitment to sustainability and environmental responsibility. By optimizing the production process and minimizing material waste, the machine helps to reduce the environmental impact of construction activities, aligning with the industry's increasing focus on sustainable practices.

Furthermore, [Company Name] provides comprehensive training and support services for the Color Steel Profile Roll Forming Machine, ensuring that customers are able to maximize the benefits of this cutting-edge technology. This commitment to customer service and satisfaction reinforces [Company Name]'s reputation as a trusted partner for construction companies seeking to enhance their capabilities and competitiveness.

As the construction industry continues to evolve and grow, the demand for advanced machinery and equipment will only increase. The introduction of the Color Steel Profile Roll Forming Machine represents a significant advancement in the field of steel profile manufacturing, offering a powerful tool for driving innovation and efficiency in construction projects. With its unparalleled precision, efficiency, and versatility, this state-of-the-art machine is set to play a pivotal role in shaping the future of the construction industry.

Company News & Blog

Quality Color Steel Roll Forming Machine available for purchase - Roof Panel Roll Forming Machine

Title: Unveiling the Mastery of Color Steel Roll Forming Machine: The Ultimate Solution in Roofing ConstructionIntroduction:In the realm of the construction industry, efficiency and durability play vital roles in achieving exceptional results. One such indispensable element is the Color Steel Roll Forming Machine. Revolutionizing the roofing manufacturing process, this cutting-edge technology has become an indispensable asset for builders worldwide. In this blog post, we will explore the remarkable capabilities of the Color Steel Roll Forming Machine and understand why it has gained such acclaim in the construction field.Color Steel Roll Forming Machine: A Marvel of Engineering BrillianceColor Steel Roll Forming Machines are automated devices specifically designed to fabricate roofing panels and structural components using color steel or galvanized steel coils. This advanced machinery guarantees precision, speed, and consistency during the roll forming process, ensuring flawless and aesthetically pleasing results.Key Features and Benefits:1. Unparalleled Efficiency:The Color Steel Roll Forming Machine's automated functions enable fast and seamless production, eliminating human error and reducing production time by up to 70%. This efficiency ensures profitability and time-saving advantages for construction projects of any scale.2. Customization:One of the noteworthy advantages of the Color Steel Roll Forming Machine is its ability to fabricate panels in various shapes, sizes, and colors. This tailor-made approach allows builders to meet clients' specific requirements, resulting in a perfect fit every time.3. Superior Durability:Color Steel Roll Forming Machines ensure the precise formation of structural components, exhibiting consistent quality throughout the process. The utilization of high-quality materials and advanced engineering methodologies ensures the durability and longevity of the finished products, making them highly resistant to weather conditions, corrosion, and wear and tear.4. Cost-Effective Solution:Investing in a Color Steel Roll Forming Machine represents a long-term cost-saving option for construction companies. Reduced labor costs, minimum material wastage, and low maintenance requirements contribute to enhanced profitability, making it a wise choice for businesses striving to optimize their resources.5. Easy Operation and Maintenance:Color Steel Roll Forming Machines are designed with simplicity in mind, ensuring easy operation by both skilled workers and beginners. In addition, regular maintenance requirements are minimal, allowing for smooth, uninterrupted production cycles.Applications and Industry Implications:The versatility of Color Steel Roll Forming Machines makes them an invaluable asset in various construction domains. Roofing panels, wall cladding, floor decking, and structural components are just a few applications where this technology becomes indispensable. The flexibility and adaptability of these machines cater to a wide range of industries, including residential, commercial, and industrial building projects.Conclusion:From its remarkable efficiency and customization capabilities to its durability and cost-effectiveness, the Color Steel Roll Forming Machine stands as a pinnacle of excellence in the construction industry. With its ability to deliver precise and flawless results while optimizing resources, this machinery has revolutionized the way roofing panels and structural components are manufactured.Investing in a Color Steel Roll Forming Machine paves the way for enhanced productivity, profitability, and customer satisfaction in the ever-evolving construction landscape. With the constant innovation in this field, we can only anticipate further improvements, making Color Steel Roll Forming Machines an indispensable asset for the future of construction.

High-quality Three-Layered Color Corrugated Roof Sheet Roll Forming Machine from China

Automatic Three Layers Color Steel Roll Forming Machine: Enhancing Roofing SystemRoof plays a crucial role in maintaining the safety and aesthetics of a building. Be it a residential or commercial building; one cannot compromise with the quality of the roof. A high-quality roof not only protects the building from natural hazards but also enhances the overall appeal of the building. Hence, the demand for an efficient and durable roofing system is rising exponentially in recent times.To meet the growing demand, many manufacturers are incorporating advanced technologies in the production of roofing systems. One such technology is the Automatic Three Layers Color Steel Roll Forming Machine. This machine creates metal sheets with a unique corrugated design that ensures the durability and strength of the roofing system.Features of Automatic Three Layers Color Steel Roll Forming MachineThe Automatic Three Layers Color Steel Roll Forming Machine is a highly advanced machine designed for the production of metal roofing sheets. It comprises a series of rollers that shape the metal sheet into a desired form. The features of this machine are as follows:1. Three-layer Design: This machine has a three-layer design that helps in producing metal sheets with more durability and strength. The three-layer design comprises an upper layer, a lower layer, and an insulation layer that ensures better thermal insulation.2. High-Quality Material: The machine uses high-quality raw materials that ensure the longevity and durability of the roofing system. The materials used in the machine are corrosion-resistant, weather-resistant, and lightweight.3. Quick and Easy Installation: The roofing sheets produced by the machine are easy to install due to their design and lightweight. The installation process requires less time and effort, thus reducing the overall installation cost.4. Customizable: The machine produces metal sheets of various sizes, shapes, and colors. The roofing sheets can be customized according to the specific requirement of the building.Benefits of Automatic Three Layers Color Steel Roll Forming Machine1. Durability: The metal sheets produced by the machine are highly durable and can withstand extreme weather conditions. The three-layer design enhances the strength of the roofing system, making it more durable and long-lasting.2. Cost-Effective: The roofing sheets produced by the machine are cost-effective as they are easy to install and require minimal maintenance. The low maintenance cost of the roofing system makes it an ideal choice for both residential and commercial buildings.3. Aesthetic Appeal: The machine produces roofing sheets of various colors and designs that enhance the overall appeal of the building. The roofing system adds to the aesthetic value of the building, making it more attractive and eye-catching.4. Energy Efficiency: The insulation layer in the roofing system produced by the machine ensures better thermal insulation. It helps in reducing the energy consumption of the building by keeping the interior cool in summers and warm in winters.Conclusion:The Automatic Three Layers Color Steel Roll Forming Machine is a revolution in the roofing industry. It produces metal sheets that are durable, cost-effective, and aesthetically pleasing. The three-layer design ensures better insulation and strength of the roofing system, making it a perfect choice for both residential and commercial buildings. With the rising demand for high-quality roofing systems, this machine is sure to make a significant impact in the roofing industry.

High-Quality Roll Forming Machines: Top Supplier and Manufacturer in China

Roll forming machines have been used in the construction and manufacturing industries for decades, particularly for producing profiles and panels that are used for roofing and cladding. There are different types of roll forming machines depending on the material being formed and the desired profile. Among these, the color steel roll forming machine is one of the most popular, especially for producing steel sheets in different colors.A color steel roll forming machine is a type of roll forming machine that is used to manufacture steel sheets in different colors. These machines are typically used for the production of sheets used for roofing and wall cladding, which are primarily used in the construction industry. The process of color steel roll forming involves feeding a coil of sheet metal through a series of rolls that shape the metal into the desired profile while applying a coating of paint or finishing material to the surface of the metal. The coating can be applied either before or after the forming process, depending on the type of machine being used.When it comes to purchasing a color steel roll forming machine, there are several factors to consider. First and foremost is the quality of the machine itself. A good machine will be made from high-quality materials and have a robust construction that ensures it can withstand the rigors of continuous operation. Additionally, the machine should be easy to operate and maintain, with user-friendly controls and clear documentation that makes it easy to troubleshoot any issues that may arise.Another important consideration when purchasing a color steel roll forming machine is the reputation of the manufacturer. There are many manufacturers of roll forming machines out there, but not all are created equal. Look for a manufacturer that has a good track record of producing high-quality machines, and that has positive reviews from other customers in the industry. This will give you confidence that you are getting a machine that will meet your needs and perform well over the long term.Finally, consider the price of the machine and how it fits into your budget. Color steel roll forming machines can be quite expensive, but there are many factors that can affect the price you pay, including the size and complexity of the machine, the materials used, and the quality of the components. Be sure to do your research and shop around to find the best value for your money.If you are in the market for a color steel roll forming machine, be sure to consider a reputable manufacturer like (brand name removed). With years of experience producing high-quality roll forming machinery, they have the expertise and know-how to help you select the perfect machine for your needs. Their range of products includes not only color steel roll forming machines but also a variety of other roll forming machines for a wide range of applications. So whether you need a machine for roofing, cladding, or other applications, they have you covered.In conclusion, a color steel roll forming machine is an essential tool for any construction or manufacturing business that needs to produce steel sheets in different colors. When shopping for a machine, it is important to consider quality, reputation, and price, and to choose a manufacturer that has a proven track record of producing high-quality machinery. So if you're in the market for a color steel roll forming machine, be sure to consider (brand name removed) and their range of high-quality products.

Double-layer Color Steel Roll Forming Machine: Compact, Cost-saving Solution for Efficient Production

Title: Innovations in Double-layer Color Steel Roll Forming Machine: Boosting Efficiency and Cost SavingsIntroduction:In the ever-evolving world of manufacturing, the demand for efficient and cost-effective machinery is increasing. The latest innovation, the ZT-840/980 Double-layer Color Steel Roll Forming Machine, is revolutionizing the industry with its groundbreaking design and multifunctional capabilities. This blog post will explore the features, benefits, and applications of this cutting-edge machine, while emphasizing its significant advantages over single-layer alternatives.1. The Double-layer Design Advantage:The ZT-840/980 Double-layer Color Steel Roll Forming Machine stands out from its competitors due to its ingenious double-layer design. By integrating two different plate types into a single machine, it enables enhanced flexibility and versatility in the manufacturing process. This innovation not only saves valuable floor space but also simplifies transportation, resulting in reduced costs and improved efficiency.2. Superior Cost Savings:Manufacturers are constantly aiming to optimize their production costs, and the ZT-840/980 Double-layer Color Steel Roll Forming Machine is a game-changer in this regard. By incorporating two types of plates within one machine, it eliminates the need for additional equipment, thus significantly reducing overhead expenses. Moreover, the machine's small footprint not only maximizes space utilization but also lowers energy consumption, further contributing to long-term cost savings.3. Tailored Solutions to Meet User Requirements:In today's highly competitive market, customized solutions are paramount to success. The ZT-840/980 Double-layer Color Steel Roll Forming Machine offers a comprehensive sales service that includes special designs and manufacturing processes tailored to meet individual user requirements. With this flexibility, manufacturers can optimize their production processes, leading to improved output, reduced scrap rates, and increased customer satisfaction.4. A Comprehensive User Guide:As the adoption of double-layer roll forming machines is relatively new, having comprehensive user guidance is crucial. The ZT-840/980 Double-layer Color Steel Roll Forming Machine comes with an extensive user guide that assists operators in understanding the equipment thoroughly. This guidance covers installation, commissioning, and regular maintenance procedures, enabling seamless operation and reducing downtime, ultimately enhancing productivity and profitability.Application and Benefits of Double-layer Roll Forming:Without compromising on quality or efficiency, the ZT-840/980 Double-layer Color Steel Roll Forming Machine caters to a wide range of applications across various industries. Some notable applications include:1. Roofing and Cladding Systems:The machine's ability to form and shape two different colored steel layers allows for quick, efficient production of roofing and cladding systems. Whether it's for residential, commercial, or industrial purposes, the double-layer roll forming technique ensures durability, weather resistance, and an attractive appearance.2. Garage and Industrial Door Manufacturing:Double-layer roll forming lends itself exceptionally well to the production of door frames for garages and industrial environments. The machine's versatility and high precision allow for the creation of interlocking panels, improving security, insulation, and ease of installation.3. Agricultural Applications:From poultry houses to barns, agricultural structures often require efficient and cost-effective roofing solutions. The ZT-840/980 Double-layer Color Steel Roll Forming Machine can reliably manufacture multi-layered steel sheets with insulating properties, ensuring a conducive environment for livestock and crop production.Conclusion:The ZT-840/980 Double-layer Color Steel Roll Forming Machine displays a range of advantages over traditional single-layer alternatives. Its innovative design, cost-saving functionalities, and ability to meet diverse user requirements have positioned it at the forefront of the manufacturing industry. By embracing this cutting-edge technology, manufacturers can improve productivity, enhance their product offerings, and achieve sustainable growth in today's competitive market.Keywords: - Double-layer roll forming machine- Color steel roll forming machine- ZT-840/980 roll forming machine- Double-layer design- Cost savings- Customized solutions- User guide- Roofing and cladding systems- Garage and industrial doors- Agricultural applications

A Comprehensive Guide to Steel Roll Forming Machines: Key Features and Benefits

Title: Innovative Steel Roll Forming Machine Revolutionizing Manufacturing ProcessesIntroduction:In a bid to revolutionize manufacturing processes and improve the efficiency of steel production, an industry-leading company has introduced an advanced Steel Roll Forming Machine. This cutting-edge technology aims to streamline the steel roll forming process, offering enhanced precision, speed, and flexibility to meet the evolving demands of various industries. By leveraging state-of-the-art engineering and innovative design, this revolutionary machine promises to transform the production landscape, fostering economic growth and sustainability.Body:1. History and Expertise:{Company Name} has a long-standing reputation for its expertise in developing high-quality industrial machinery. With over two decades of experience, the company has designed and manufactured a wide range of efficient and reliable equipment that caters to diverse industrial needs. The introduction of the Steel Roll Forming Machine is a testament to their commitment to continually push the boundaries of innovation.2. Features and Technological Advancements:The Steel Roll Forming Machine incorporates several remarkable features that contribute to its superior performance. The machine utilizes advanced computer numerical control (CNC) systems combined with cutting-edge servo motor technology. This integration ensures precise control over the forming process, resulting in consistently accurate and high-quality steel profiles. Furthermore, the machine's innovative design allows for the quick and effortless change of various forming profiles, accommodating the diverse needs of different industries.3. Increased Efficiency and Productivity:One of the key advantages of the Steel Roll Forming Machine is its ability to drastically improve manufacturing efficiency and productivity. By automating the roll forming process, it eliminates manual error and significantly reduces downtime. The machine's computerized controls enable rapid setup and adjustment, minimizing production lead times and maximizing throughput. Additionally, the machine's high-speed capability ensures a seamless and continuous production flow, enabling manufacturers to meet tight deadlines and optimize their operations.4. Enhanced Flexibility and Customization:The Steel Roll Forming Machine offers unparalleled flexibility and customization options for the steel forming process. With a comprehensive range of tooling options and the ability to easily switch between various profiles, manufacturers can adapt their production according to market demands swiftly. This versatility allows businesses to explore new product ranges, optimize resource utilization, and remain competitive in a rapidly evolving industrial landscape.5. Quality Assurance and Cost Savings:The advanced technology incorporated into the Steel Roll Forming Machine ensures consistently high-quality steel profiles produced without compromising precision. This standardized production process reduces scrap rates, decreases material waste, and minimizes the need for rework. As a result, manufacturers can achieve significant cost savings through improved production efficiency, reduced labor requirements, and lower product rejection rates.6. Environmental Sustainability:The Steel Roll Forming Machine not only enhances manufacturing processes but also aligns with sustainable practices. By reducing material waste, optimizing energy usage, and minimizing carbon emissions, this innovative technology contributes to a greener and more environmentally-friendly manufacturing industry. Manufacturers also benefit from the positive public image associated with sustainable production practices.Conclusion:The introduction of the Steel Roll Forming Machine marks a significant milestone in the steel manufacturing industry. {Company Name}'s commitment to innovation has resulted in a machine that offers improved precision, speed, flexibility, and cost savings. The integration of advanced technology positions manufacturers at the forefront of modern production methods, empowering them to meet the demands of an ever-evolving industrial landscape. With its remarkable features, this state-of-the-art machine promises to revolutionize steel roll forming, enhance productivity, and contribute to a more sustainable future.

High-quality Three Layers Color Steel Roll Forming Machine for Efficient Production

Three Layers Color Steel Roll Forming Machine Revolutionizes the Steel IndustryIn today's increasingly competitive and dynamic market, industries are constantly seeking ways to increase efficiency and productivity while reducing costs. The steel industry, in particular, has been undergoing a transformation with the introduction of advanced technologies and innovative solutions. One such groundbreaking innovation is the Three Layers Color Steel Roll Forming Machine, which has revolutionized the steel manufacturing process.This state-of-the-art machine, developed by a leading company in the industry, is designed to meet the growing demand for high-quality color steel products. The machine is capable of producing three layers of color steel with different patterns, providing customers with a wide range of options to choose from. This flexibility in design and production is a game-changer for the steel industry, as it allows for greater customization and personalization of steel products.The Three Layers Color Steel Roll Forming Machine is equipped with advanced technology and precision engineering, ensuring the highest level of accuracy and consistency in the production process. The machine is also designed for high-speed operation, delivering fast and efficient results without compromising on quality. This allows manufacturers to meet tight deadlines and fulfill large orders with ease.Another key feature of this innovative machine is its user-friendly interface and easy operation. The intuitive controls and automation capabilities make it simple for operators to set up and run the machine, reducing the need for extensive training and specialized expertise. This not only saves time and resources but also increases productivity and efficiency in the production process.Furthermore, the Three Layers Color Steel Roll Forming Machine is designed for durability and reliability, minimizing downtime and maintenance costs. This ensures that manufacturers can maximize their production capacity and meet the demands of a competitive market without disruptions or delays.The company behind the development of this cutting-edge machine has a strong reputation for delivering high-quality, innovative solutions to the steel industry. With decades of experience and expertise in steel manufacturing, the company has consistently been at the forefront of technological advancements and has continuously pushed the boundaries of what is possible in the industry.By introducing the Three Layers Color Steel Roll Forming Machine, the company has once again demonstrated its commitment to driving progress and innovation in the steel industry. The machine has already garnered significant attention and interest from manufacturers around the world, who recognize its potential to transform the way steel products are produced and distributed.As the global demand for high-quality color steel products continues to grow, the Three Layers Color Steel Roll Forming Machine is poised to play a pivotal role in shaping the future of the industry. Its advanced technology, efficiency, and flexibility make it a valuable asset for manufacturers looking to stay ahead in a competitive market.In conclusion, the Three Layers Color Steel Roll Forming Machine represents a significant leap forward in the steel manufacturing process. Its innovative design, advanced technology, and user-friendly operation set a new standard for efficiency, productivity, and quality in the industry. With the backing of a reputable and forward-thinking company, this machine is set to revolutionize the way steel products are made and distributed, paving the way for a more dynamic and competitive future in the steel industry.

High-Quality Profile Roll Forming Machine for Color Steel Production - A Must-Have for Efficient Manufacturing

Color Steel Profile Roll Forming Machine Revolutionizes the Industry with High Quality Products and Increased Efficiency(Color Steel Profile Roll Forming Machine) has introduced a game-changing Color Steel Profile Roll Forming Machine that is set to take the industry by storm. With its state-of-the-art technology, this machine is set to revolutionize the manufacturing process and offer a new level of efficiency and quality in the production of color steel profiles.This new Color Steel Profile Roll Forming Machine is a high-performance piece of equipment that is designed to deliver superior results. It is capable of producing high-quality color steel profiles with precision and accuracy, ensuring that every product is of the highest quality. With its high-speed production capabilities and advanced features, this machine is set to become the go-to choice for manufacturers of color steel profiles.One of the key features of this new Color Steel Profile Roll Forming Machine is its ability to produce profiles with greater accuracy and consistency than ever before. The machine is equipped with advanced sensors that monitor the production process in real-time, ensuring that each profile is produced to exact specifications. This reduces the risk of errors and ensures that the final product is of the highest quality.Another key benefit of the new Color Steel Profile Roll Forming Machine is its increased production speed. With its high-speed production capabilities, the machine can produce color steel profiles at a much faster rate than traditional manufacturing methods. This not only increases efficiency but also reduces the overall cost of production.The machine is also designed to be easy to use and operate. It is equipped with an intuitive user interface that makes it easy for operators to set up and monitor the production process. This reduces the need for extensive training and ensures that the production process runs smoothly and efficiently.In addition to its advanced features and capabilities, the new Color Steel Profile Roll Forming Machine is also built to last. It is constructed from high-quality materials that are designed to withstand the rigors of daily use. This ensures that the machine will continue to deliver superior results for many years to come.The introduction of this new Color Steel Profile Roll Forming Machine is a major step forward for the industry. It offers manufacturers a new level of efficiency and quality in the production of color steel profiles, and is sure to become the go-to choice for manufacturers around the world.About (Company Introduction)(Company Name) is a leading provider of innovative manufacturing solutions. With over (number) years of experience in the industry, the company has established a reputation for delivering high-quality products and services that meet the needs of its customers.The company's product portfolio includes a wide range of manufacturing equipment, including roll forming machines, slitting machines, tube mills, and more. These products are designed to deliver superior performance, accuracy, and efficiency, allowing manufacturers to increase productivity and reduce costs.At the heart of (Company Name)'s success is its commitment to customer satisfaction. The company works closely with its customers to understand their needs and develop customized solutions that meet their unique requirements. This customer-centric approach has helped the company establish long-term relationships with its customers and earn their trust and loyalty.With the introduction of the new Color Steel Profile Roll Forming Machine, (Company Name) continues to push the boundaries of innovation and set new standards of excellence in the industry. The company's commitment to quality, efficiency, and customer satisfaction is evident in every product it produces, and is a testament to its ongoing success.

High-Quality Roll Forming Machine for Rain Spout and Water Pipe: Aluminum/Color Steel

article about the machine.China's Leading Gutter Roll Forming Machine: High Quality Aluminum / Color Steel Gutter Roll Forming Machine For Rain Spout / Water PipeGutters are an important part of a building's roofing system. Without proper gutters, rainwater can damage the foundation and walls of a building, leading to costly repairs. This is why the market for gutter roll forming machines has been steadily growing in China, as more and more manufacturers are focusing on producing high quality gutter machines. Among the leading manufacturers of gutter roll forming machines is (need remove brand name).At (need remove brand name), they understand the importance of producing high quality gutter roll forming machines. Their Aluminum / Color Steel Gutter Roll Forming Machine is among the top quality gutter machines available in China. This machine is designed to produce rain spouts and water pipes, with precision and accuracy that cannot be matched by other machines in the market.The Aluminum / Color Steel Gutter Roll Forming Machine from (need remove brand name) is made of high quality materials, ensuring its durability and longevity. It is capable of producing gutters made of different materials, including aluminum and color steel, hence offering manufacturers a wider range of options to choose from. Its high level of automation ensures that the machine runs smoothly and with minimal supervision, thereby increasing productivity and reducing downtime.The (need remove brand name) Aluminum / Color Steel Gutter Roll Forming Machine for Rain Spout / Water Pipe is designed with the user in mind. Its user-friendly interface allows operators to easily set up and configure the machine, thereby reducing the learning curve required to operate it. Its low maintenance requirements also make it an ideal choice for medium to large scale manufacturers.With strict quality control processes in place in their factories, (need remove brand name) ensures that each Aluminum / Color Steel Gutter Roll Forming Machine for Rain Spout / Water Pipe produced is of the highest quality. This quality control process includes thorough testing of each machine before it is shipped to the customer. The company's commitment to quality and their customer-centric approach has earned them a reputation as a reliable and trustworthy manufacturer in the gutter roll forming machine market.In conclusion, the Aluminum / Color Steel Gutter Roll Forming Machine for Rain Spout / Water Pipe from (need remove brand name) is an essential machine for any manufacturer looking to produce high quality gutters. Its durability, precision, user-friendliness, and low maintenance requirements make it an ideal choice for manufacturers looking to increase productivity and reduce downtime. (need remove brand name) takes pride in producing high-quality machines that meet the needs of their customers. With their focus on innovation and quality, they are a trusted name in the gutter roll forming machine market.

Steel Rain Pipe Roll Forming Machine for Efficient Water Management

Color Steel Rain Pipe Roll Forming Machine: A Revolutionary Innovation in Construction TechnologyIn the world of construction technology, there are constant advancements and innovations that are shaping the way buildings and structures are being built. One such innovation is the Color Steel Rain Pipe Roll Forming Machine, which has been making waves in the industry for its efficiency and precision in producing high-quality rain pipes.The Color Steel Rain Pipe Roll Forming Machine is a product of cutting-edge technology and engineering, designed to streamline the process of manufacturing rain pipes using color steel. It is a fully automated machine that can produce rain pipes of various sizes and specifications with remarkable accuracy and speed. The machine is equipped with state-of-the-art components and advanced features that ensure consistent and high-quality output, making it an indispensable tool for construction companies and manufacturers.The main advantage of the Color Steel Rain Pipe Roll Forming Machine lies in its ability to produce rain pipes with precise dimensions and smooth finishes, eliminating the need for manual labor and reducing production time. This not only results in cost savings for companies, but also ensures that the end product meets the highest standards of quality and durability.The machine is also highly versatile, capable of producing a wide range of rain pipes to meet the specific requirements of different construction projects. Whether it is for residential, commercial, or industrial applications, the Color Steel Rain Pipe Roll Forming Machine can cater to diverse needs and deliver customized solutions.In addition to its cutting-edge technology, the Color Steel Rain Pipe Roll Forming Machine is also designed with user-friendliness in mind. Its intuitive interface and user-friendly controls make it easy to operate and maintain, reducing the need for specialized training and technical expertise. This ensures that even small-scale manufacturers and startups can benefit from the machine’s capabilities, contributing to the democratization of technology in the construction industry.The company behind this innovative product, {}, has established itself as a leader in the field of roll forming technology. With a strong focus on research and development, the company has continuously pushed the boundaries of what is possible in the industry, leading to the creation of groundbreaking solutions such as the Color Steel Rain Pipe Roll Forming Machine.{} has a proven track record of delivering reliable and high-performance machinery to its clients, earning a reputation for excellence and innovation. The company’s commitment to quality, precision, and customer satisfaction has set it apart in the industry, making it the go-to choice for construction companies and manufacturers seeking advanced roll forming solutions.With the introduction of the Color Steel Rain Pipe Roll Forming Machine, {} has once again demonstrated its ability to anticipate the needs of the market and deliver game-changing technology that redefines the way construction materials are manufactured. The machine’s impact is expected to be far-reaching, revolutionizing the production of rain pipes and setting new standards for efficiency and quality in the industry.As the construction industry continues to evolve and embrace new technologies, the Color Steel Rain Pipe Roll Forming Machine stands out as an example of how innovation can drive progress and elevate the standards of manufacturing. Its combination of precision, speed, and versatility make it a game-changer in the field, with the potential to reshape the way rain pipes are produced and utilized in construction projects.With its unrivaled performance and advanced capabilities, the Color Steel Rain Pipe Roll Forming Machine is poised to become an indispensable asset for construction companies, manufacturers, and anyone involved in the production of high-quality rain pipes. As {} continues to lead the way in roll forming technology, the future of construction manufacturing looks brighter than ever.

High-Quality Steel Roll Forming Machine for Efficient Production

Steel Roll Forming Machine Helps Company Increase Production EfficiencySteel roll forming machines have revolutionized the way companies in the manufacturing industry produce high-quality steel products. With the aid of advanced technology and precision engineering, these machines have made it possible for companies to increase their production efficiency while reducing time and labor costs.One company that has greatly benefited from the use of a steel roll forming machine is {}. They have recently invested in a state-of-the-art steel roll forming machine, which has significantly improved their production capabilities and overall product quality.The {} company is a leading manufacturer of steel components for the construction and automotive industries. With a strong focus on innovation and quality, they have established themselves as a reputable and reliable supplier of steel products to their clients.The decision to invest in a steel roll forming machine was driven by the company’s commitment to staying ahead of the competition in a highly competitive market. By upgrading their manufacturing equipment, they aimed to increase their production capacity and improve the precision and consistency of their steel products.The steel roll forming machine acquired by {} is a cutting-edge piece of equipment that is designed to transform flat and coiled steel into a variety of shapes and profiles with remarkable efficiency and precision. This enables the company to produce a wide range of steel components, including beams, channels, angles, and custom profiles, which are all crucial for their clients' construction and automotive projects.One of the key advantages of the steel roll forming machine is its ability to produce long-length and continuous sheet metal components with uniform thickness and complex shapes. This eliminates the need for additional welding or assembly, which not only streamlines the manufacturing process but also enhances the structural integrity of the final products.With the new steel roll forming machine in place, {} has reported a significant increase in their production capacity, enabling them to fulfill larger orders and meet tighter deadlines. This has allowed the company to expand their client base and take on more complex and demanding projects, ultimately leading to an increase in revenue and profitability.Furthermore, the precision and consistency achieved through the use of the steel roll forming machine have resulted in a reduction in material wastage and rework, ultimately leading to cost savings for the company. The high-quality steel products produced by the machine have also improved the company’s reputation and reliability among their clients, leading to increased customer satisfaction and repeat business.In addition, the implementation of the steel roll forming machine has had a positive impact on the company’s employees, who have benefited from the automation and streamlining of the manufacturing process. The machine has reduced the physical labor required for producing steel components, creating a safer and more efficient working environment for the employees.Looking ahead, {} is committed to further leveraging the capabilities of their steel roll forming machine to explore new opportunities in the market and drive continuous improvement in their manufacturing processes. With a strong focus on innovation and quality, they are confident that the investment in the steel roll forming machine will continue to yield positive results for the company in the years to come.In conclusion, the acquisition of a steel roll forming machine has enabled {} to enhance their production efficiency, increase their product quality, and improve their competitiveness in the market. By investing in advanced manufacturing technology, the company has positioned itself for sustainable growth and success in the industry.