Profile Forming Equipment for Color Steel: A Complete Guide

By:Admin

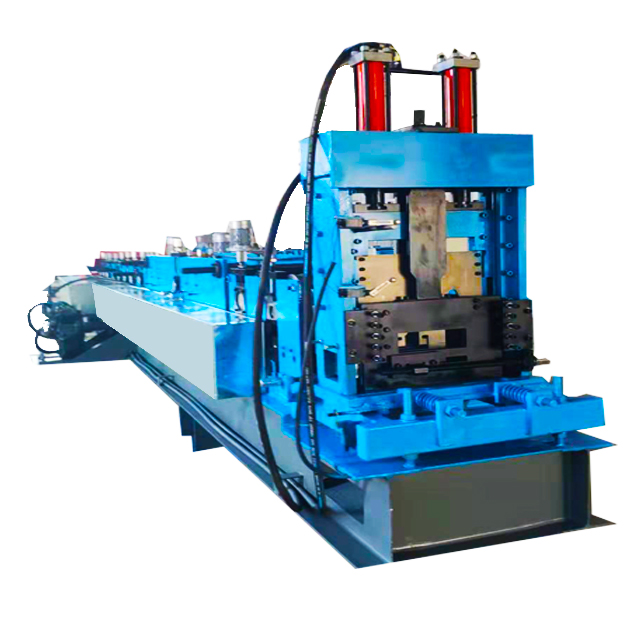

[Company Name], a leading provider of metal forming solutions, has recently added a new product to their lineup - the Color Steel Profile Forming Equipment. This latest addition is set to further solidify the company’s position in the metal forming industry and expand their capabilities in providing high-quality, customized solutions for their customers.

The Color Steel Profile Forming Equipment is a state-of-the-art machine that is designed to precisely shape and cut metal sheets into various profiles and designs with the application of colored steel. This new equipment allows [Company Name] to offer a wider range of options for their customers, enabling them to create intricate and visually appealing metal profiles that are widely used in modern architecture, construction, and other industrial applications.

With the addition of the Color Steel Profile Forming Equipment, [Company Name] is poised to meet the growing demand for more intricate and aesthetically pleasing metal profiles in the market. This new equipment enables the company to expand its product offerings and cater to a broader range of customer needs, from simple metal panels to complex architectural elements.

[Company Name] has been at the forefront of the metal forming industry for several years, and the addition of the Color Steel Profile Forming Equipment is a testament to their commitment to innovation and continuously improving their capabilities. The company’s dedication to providing cutting-edge solutions has earned them a reputation as a trusted and reliable partner for businesses in need of metal forming services.

The Color Steel Profile Forming Equipment is just the latest example of [Company Name]’s dedication to staying ahead of the curve and anticipating the evolving needs of their customers. By investing in the latest technology and equipment, the company is positioning itself to remain a leader in the metal forming industry for years to come.

In addition to the new equipment, [Company Name] also offers a range of other metal forming solutions, including roll forming machines, slitting lines, and cut-to-length lines. The company’s team of skilled engineers and technicians work closely with customers to develop customized solutions that meet their specific requirements, ensuring that every project is completed to the highest standards of quality and precision.

With the Color Steel Profile Forming Equipment now in their arsenal, [Company Name] is better equipped than ever to help their customers bring their metal forming projects to life. Whether it’s creating custom architectural elements, decorative facades, or industrial components, the company is ready to take on projects of any size and complexity.

The addition of the Color Steel Profile Forming Equipment marks an exciting new chapter for [Company Name]. With this latest investment, the company is not only expanding its capabilities but also reaffirming its commitment to providing the best metal forming solutions on the market. Customers can now expect even greater flexibility, precision, and creativity in their metal forming projects, making [Company Name] the go-to partner for all their metal shaping needs.

In conclusion, the addition of the Color Steel Profile Forming Equipment is a significant milestone for [Company Name] and a testament to their commitment to excellence and innovation in the metal forming industry. Customers can look forward to an expanded range of options and enhanced capabilities, further solidifying the company’s position as a leader in the field. With this latest addition, [Company Name] is well-equipped to meet the evolving needs of their customers and continue to push the boundaries of what is possible in metal forming.

Company News & Blog

Futuristic Color Steel Roll Forming Machine: the Way Forward

Fully Automatic Color Steel Roll Forming Machine Revolutionizes Production ProcessIn today’s fast-paced industrial landscape, efficiency is key. In order to meet demanding marketplace requirements, manufacturers need to employ sophisticated equipment that can handle high volumes of production, while maintaining consistently high quality output. That’s why a new Fully Automatic Color Steel Roll Forming Machine has made waves in the industry, as it streamlines production processes and generates significant time and cost savings.Manufactured by [remove brand name] Company, a global leader in industrial equipment production, the Fully Automatic Color Steel Roll Forming Machine sets a new standard in industrial machinery. The machine boasts advanced technological features, such as a touch screen user interface, fully automatic operation, and a high-precision servo motor system. Additionally, the machine has been engineered to create high-quality finished products with minimal wastage - an important factor in today’s increasingly environmentally-conscious marketplace.According to [remove brand name] Company representatives, the Fully Automatic Color Steel Forming Machine is designed with user-friendliness and accessibility in mind. Unlike traditional roll forming machines, which are labor-intensive and require a significant amount of operator expertise, this new equipment is highly automated and can be operated by personnel with basic training. “Our aim is to simplify the roll forming process and make it more accessible for manufacturers of all sizes,” explains [remove brand name] spokesperson Alex Wang. “By automating certain tasks, the machine eliminates the need for manual intervention, which greatly increases efficiency and reduces the risk of errors.”In addition to being user-friendly, the Fully Automatic Color Steel Roll Forming Machine is customizable. The machine can create a variety of products, including roofing sheets, wall panels, and floor decking - all with different configurations and thicknesses. Because of its flexibility and versatility, the machine has been a game-changer for manufacturers in the construction industry, as it can easily adapt to the specific needs of different projects.Another important feature of the Fully Automatic Color Steel Roll Forming Machine is its high level of precision. According to [remove brand name] engineers, the machine’s servo motor system is capable of accurately controlling the movement of the rollers, which ensures that the resulting products are of uniform quality. This is particularly important for manufacturers who need to meet strict industry standards for their products.One of the primary benefits of the Fully Automatic Color Steel Roll Forming Machine is its ability to save time and money for manufacturers. By automating certain tasks and minimizing the risk of errors, the machine significantly increases production rates and reduces wastage. And because it requires less labor input, manufacturers can reduce their workforce and save money on labor costs. “We’re seeing manufacturers save up to 50% in labor costs thanks to the Fully Automatic Color Steel Roll Forming Machine,” states Alex Wang. “And that’s just the beginning - as they continue to use the machine, they’ll see additional savings in terms of product quality and efficiency.”Overall, the Fully Automatic Color Steel Roll Forming Machine marks a significant step forward in industrial machinery technology. By combining user-friendliness, customization, precision, and efficiency, the machine has become a favorite for manufacturers across the globe. And as the manufacturing industry continues to evolve, it’s clear that equipment like this will play an important role in shaping the future of production.

A Comprehensive Guide to Steel Roll Forming Machines: Key Features and Benefits

Title: Innovative Steel Roll Forming Machine Revolutionizing Manufacturing ProcessesIntroduction:In a bid to revolutionize manufacturing processes and improve the efficiency of steel production, an industry-leading company has introduced an advanced Steel Roll Forming Machine. This cutting-edge technology aims to streamline the steel roll forming process, offering enhanced precision, speed, and flexibility to meet the evolving demands of various industries. By leveraging state-of-the-art engineering and innovative design, this revolutionary machine promises to transform the production landscape, fostering economic growth and sustainability.Body:1. History and Expertise:{Company Name} has a long-standing reputation for its expertise in developing high-quality industrial machinery. With over two decades of experience, the company has designed and manufactured a wide range of efficient and reliable equipment that caters to diverse industrial needs. The introduction of the Steel Roll Forming Machine is a testament to their commitment to continually push the boundaries of innovation.2. Features and Technological Advancements:The Steel Roll Forming Machine incorporates several remarkable features that contribute to its superior performance. The machine utilizes advanced computer numerical control (CNC) systems combined with cutting-edge servo motor technology. This integration ensures precise control over the forming process, resulting in consistently accurate and high-quality steel profiles. Furthermore, the machine's innovative design allows for the quick and effortless change of various forming profiles, accommodating the diverse needs of different industries.3. Increased Efficiency and Productivity:One of the key advantages of the Steel Roll Forming Machine is its ability to drastically improve manufacturing efficiency and productivity. By automating the roll forming process, it eliminates manual error and significantly reduces downtime. The machine's computerized controls enable rapid setup and adjustment, minimizing production lead times and maximizing throughput. Additionally, the machine's high-speed capability ensures a seamless and continuous production flow, enabling manufacturers to meet tight deadlines and optimize their operations.4. Enhanced Flexibility and Customization:The Steel Roll Forming Machine offers unparalleled flexibility and customization options for the steel forming process. With a comprehensive range of tooling options and the ability to easily switch between various profiles, manufacturers can adapt their production according to market demands swiftly. This versatility allows businesses to explore new product ranges, optimize resource utilization, and remain competitive in a rapidly evolving industrial landscape.5. Quality Assurance and Cost Savings:The advanced technology incorporated into the Steel Roll Forming Machine ensures consistently high-quality steel profiles produced without compromising precision. This standardized production process reduces scrap rates, decreases material waste, and minimizes the need for rework. As a result, manufacturers can achieve significant cost savings through improved production efficiency, reduced labor requirements, and lower product rejection rates.6. Environmental Sustainability:The Steel Roll Forming Machine not only enhances manufacturing processes but also aligns with sustainable practices. By reducing material waste, optimizing energy usage, and minimizing carbon emissions, this innovative technology contributes to a greener and more environmentally-friendly manufacturing industry. Manufacturers also benefit from the positive public image associated with sustainable production practices.Conclusion:The introduction of the Steel Roll Forming Machine marks a significant milestone in the steel manufacturing industry. {Company Name}'s commitment to innovation has resulted in a machine that offers improved precision, speed, flexibility, and cost savings. The integration of advanced technology positions manufacturers at the forefront of modern production methods, empowering them to meet the demands of an ever-evolving industrial landscape. With its remarkable features, this state-of-the-art machine promises to revolutionize steel roll forming, enhance productivity, and contribute to a more sustainable future.

Automatic Color Steel Roll Forming Machine: Advanced Technology for Efficient Production

Fully Automatic Color Steel Roll Forming Machine Revolutionizes Production Process[City, Date] - [Company Name] is proud to announce the launch of its latest innovation, the Fully Automatic Color Steel Roll Forming Machine. This state-of-the-art technology is set to revolutionize the production process for color steel products, offering increased efficiency, precision, and quality.The Fully Automatic Color Steel Roll Forming Machine is designed to meet the growing demand for high-quality color steel products in various industries. With its advanced automation and superior engineering, this machine is capable of producing color steel sheets and panels with unmatched speed and accuracy.The machine's cutting-edge technology allows for precise shaping and sizing of color steel materials, ensuring consistency in product dimensions and appearance. Its fully automated operation minimizes human intervention, reducing the risk of errors and increasing overall production efficiency.With the ability to handle a wide range of color steel materials, the Fully Automatic Color Steel Roll Forming Machine offers unparalleled versatility for manufacturers. Whether producing roofing sheets, wall panels, or other color steel products, this machine delivers exceptional results every time.In addition to its advanced technical capabilities, the Fully Automatic Color Steel Roll Forming Machine is also designed for user-friendly operation. Its intuitive controls and interface make it easy for operators to set up and monitor the production process, while its durable construction ensures long-term reliability and performance."We are thrilled to introduce the Fully Automatic Color Steel Roll Forming Machine to the market," said [Company Name]'s spokesperson. "This innovative technology represents a significant leap forward in the production of color steel products, offering our customers a game-changing solution that will enhance their competitiveness and productivity."[Company Name] is a leading provider of roll forming machines and solutions, with a strong focus on innovation and customer satisfaction. With a track record of delivering cutting-edge technology and exceptional service, the company has earned a reputation as a trusted partner for manufacturers in the color steel industry.As a pioneer in roll forming technology, [Company Name] is committed to continuous research and development, staying ahead of industry trends and driving progress through innovation. The launch of the Fully Automatic Color Steel Roll Forming Machine is a testament to the company's dedication to delivering advanced solutions that meet the evolving needs of its customers.With its commitment to quality, reliability, and customer satisfaction, [Company Name] is well positioned to lead the way in the roll forming industry. The Fully Automatic Color Steel Roll Forming Machine is the latest example of the company's unwavering dedication to excellence and its ongoing pursuit of technological advancement.Manufacturers in the color steel industry can now look forward to a new era of production efficiency and quality, thanks to the revolutionary capabilities of the Fully Automatic Color Steel Roll Forming Machine. As this cutting-edge technology becomes more widely adopted, it is set to bring about transformative change in the way color steel products are manufactured, setting new standards for speed, precision, and performance.For more information about the Fully Automatic Color Steel Roll Forming Machine and other roll forming solutions, please visit [Company Name]'s website or contact their sales team for a personalized consultation.

High-quality Wall Panel Roll Forming Machine for Efficient Production

Color Steel Wall Panel Roll Forming Machine Revolutionizing the Construction IndustryThe construction industry has always been at the forefront of technological advancements, constantly seeking new ways to improve efficiency and productivity. One such innovation that is revolutionizing the industry is the Color Steel Wall Panel Roll Forming Machine, produced by a leading machinery manufacturer. This cutting-edge machine is changing the way steel wall panels are produced, making the process faster, more precise, and more cost-effective.This state-of-the-art machine is capable of producing high-quality steel wall panels with unparalleled efficiency. By utilizing advanced roll forming technology, the machine is able to fabricate steel panels with exceptional precision and consistency, ensuring that each panel meets the highest standards of quality. This level of precision is crucial in the construction industry, where even the slightest deviation from specifications can lead to costly delays and rework.The Color Steel Wall Panel Roll Forming Machine is also incredibly versatile, offering the ability to produce panels of various shapes, sizes, and designs. This flexibility enables construction companies to meet the diverse needs of their clients, allowing for greater customization and innovation in architectural design. Additionally, the machine is capable of working with a wide range of materials, including galvanized steel, stainless steel, and aluminum, further expanding its applications in the construction industry.One of the most significant advantages of this machine is its speed and efficiency. Traditional methods of producing steel wall panels are often labor-intensive and time-consuming, requiring multiple steps and processes. The Color Steel Wall Panel Roll Forming Machine, on the other hand, is able to produce panels at a much faster rate, significantly reducing production time and costs. This increased efficiency not only benefits manufacturers but also allows construction projects to be completed more quickly, helping to meet deadlines and timelines.In addition to its speed and precision, the Color Steel Wall Panel Roll Forming Machine is also designed with user-friendliness in mind. The machine is equipped with intuitive controls and easy-to-use interfaces, allowing operators to quickly set up and adjust the production process as needed. This user-friendly design reduces the need for extensive training and expertise, making the machine accessible to a wide range of operators and technicians.As a leading manufacturer of roll forming machinery, the company behind the Color Steel Wall Panel Roll Forming Machine has a long-standing reputation for delivering innovative and reliable solutions to the construction industry. With a strong emphasis on research and development, the company continuously strives to push the boundaries of technology, introducing new features and capabilities that address the evolving needs of the industry.Furthermore, the company is dedicated to providing exceptional customer support and service, ensuring that clients receive the guidance and assistance they need to maximize the value of their investment. This commitment to customer satisfaction has established the company as a trusted partner for construction companies and manufacturers around the world.The introduction of the Color Steel Wall Panel Roll Forming Machine represents a significant milestone in the construction industry, offering a more efficient, precise, and cost-effective solution for producing steel wall panels. As the demand for sustainable and aesthetically pleasing building materials continues to grow, this innovative machine is poised to play a pivotal role in shaping the future of construction.In conclusion, the Color Steel Wall Panel Roll Forming Machine is a game-changer in the construction industry, offering unparalleled speed, precision, and versatility in the production of steel wall panels. With its user-friendly design and strong support from the manufacturer, this machine is set to elevate the standards of efficiency and quality in construction projects around the world. As the industry continues to embrace technological advancements, it is clear that this revolutionary machine will be at the forefront of innovation and progress.

High-quality Profile Forming Equipment for Color Steel Manufacturing

Color Steel Profile Forming Equipment has been making waves in the construction industry with its advanced technology and high-quality products. This equipment is designed to form color steel coils into various profiles, making it an essential tool for creating durable and attractive buildings.The company behind this innovative equipment, {company name}, is a leading provider of solutions for the construction industry. With years of experience and a commitment to excellence, they have built a reputation for delivering top-notch products and services. Their color steel profile forming equipment is no exception, offering a range of benefits for construction projects of all sizes.One of the key advantages of {company name}'s color steel profile forming equipment is its precision and efficiency. The equipment is designed to accurately form color steel coils into the desired profiles, ensuring a perfect fit and finish every time. This level of precision is essential for creating high-quality buildings that not only look great but also stand the test of time.In addition to precision, the equipment is also highly efficient, allowing for fast and seamless production. This is critical for construction projects that require quick turnaround times, as the equipment can significantly speed up the process of forming color steel profiles. As a result, construction companies can save time and money without sacrificing quality.Furthermore, {company name}'s color steel profile forming equipment is incredibly versatile, able to create a wide range of profiles to suit different project requirements. Whether it's for roofing, wall cladding, or other building elements, the equipment can handle various shapes and sizes with ease. This versatility makes it a valuable investment for construction companies looking to expand their capabilities and take on a diverse range of projects.Another standout feature of {company name}'s color steel profile forming equipment is its durability and reliability. Built to withstand the rigors of heavy-duty use, the equipment is designed to last for years without compromising on performance. This is essential for construction companies that rely on their equipment to deliver consistent results day in and day out.Moreover, {company name} prides itself on providing exceptional service and support to its customers. From initial consultation to installation and ongoing maintenance, the company is committed to ensuring that its clients have a positive experience with its products. This level of dedication has helped {company name} build strong, long-lasting relationships with construction companies around the world.In light of the growing demand for color steel profile forming equipment, {company name} continues to innovate and improve its products. Recent advancements in technology have further enhanced the performance and efficiency of the equipment, making it an even more valuable asset for construction projects. With a focus on staying ahead of industry trends, {company name} is well-positioned to meet the evolving needs of its customers.Overall, {company name}'s color steel profile forming equipment has set a new standard for quality and performance in the construction industry. With its precision, efficiency, versatility, durability, and exceptional service, the equipment has proven to be a game-changer for construction companies worldwide. As the company continues to evolve and innovate, it is poised to remain a leading provider of solutions for the construction industry for years to come.

Creating Strong and Durable Components with Color Steel Profile Forming Technology

Title: Innovative Color Steel Profile Forming Equipment Revolutionizes Building and Construction IndustryIntroduction:[Company Name], a leading global manufacturer of cutting-edge industrial equipment, proudly introduces its latest innovation in the field of color steel profile forming. Developed after years of research and development, this state-of-the-art equipment promises to revolutionize the building and construction industry with its advanced features, unmatched quality, and exceptional precision.Paragraph 1:The new color steel profile forming equipment encompasses cutting-edge technologies to meet the increasing demand for durable, aesthetically pleasing, and energy-efficient building materials. This equipment streamlines the traditional manufacturing process, reducing labor costs and optimizing production efficiency. By combining [Company Name's] industry expertise and extensive experience, this revolutionary solution is set to transform the way buildings are constructed.Paragraph 2:Offering unparalleled versatility, the color steel profile forming equipment is capable of producing profiles in a wide range of dimensions and shapes. With its seamless integration into existing production lines, manufacturers can easily adapt to varying project requirements, allowing for swift and efficient customization of products. This flexibility gives architects and construction companies freedom in designing unique and visually appealing structures, while meeting the highest industry standards.Paragraph 3:The precision and accuracy of the color steel profile forming equipment are second to none. Equipped with advanced software and intelligent controls, every step of the manufacturing process is meticulously monitored, ensuring impeccable quality and consistency. The equipment is designed to minimize material waste, greatly enhancing cost-effectiveness, while maintaining superior structural integrity. These characteristics make it an ideal choice for large-scale commercial projects as well as residential constructions.Paragraph 4:Incorporating cutting-edge safety features, the color steel profile forming equipment prioritizes the well-being of operators and workers. The machinery is equipped with state-of-the-art sensors and emergency stop systems to prevent accidents and enhance workplace safety. Moreover, the user-friendly interface and intuitive controls make operating the equipment effortless, reducing the risk of error and improving overall efficiency.Paragraph 5:The advent of the color steel profile forming equipment aligns with the growing demand for environmentally friendly and sustainable construction practices. By utilizing high-quality raw materials and minimizing waste during production, this equipment significantly reduces the carbon footprint associated with conventional building methods. Moreover, the durability and longevity of the profiles produced using this equipment ensure reduced maintenance and replacement costs throughout the lifespan of the structures.Paragraph 6:[Company Name] remains committed to delivering exceptional after-sales support to its customers. A dedicated team of engineers and technicians is available to provide 24/7 technical assistance, addressing any queries or concerns promptly. Additionally, the company offers comprehensive training programs ensuring operators are well-equipped to harness the full potential of the color steel profile forming equipment.Conclusion:In summary, [Company Name's] groundbreaking color steel profile forming equipment is set to transform the building and construction industry, offering unparalleled versatility, exceptional precision, and advanced safety features. With its commitment to sustainability and customer support, the company is revolutionizing the way structures are built and providing architects and construction firms with the tools to create groundbreaking designs. The introduction of this innovative equipment marks a significant milestone in the evolution of the industry, driving it towards a more sustainable and efficient future.

Steel Roll Forming Machine: A Revolution in Construction Industry

Title: Innovative Metal Forming Machine Revolutionizes Steel Roll ManufacturingIntroduction:Steel roll manufacturing has witnessed a significant breakthrough with the introduction of a cutting-edge metal forming machine. This revolutionary technology, developed by leading industry experts {}, promises to redefine the process of producing high-quality IBR color steel rolls. The advanced capabilities and efficiency of this machine are set to transform the steel roll manufacturing sector, enabling companies to meet the growing demands of various industries.Body:1. Traditional Challenges and Limitations:Metal forming for IBR color steel rolls has traditionally been a time-consuming and labor-intensive process. The conventional methods involve multiple stages of manual labor, leading to inconsistencies, lower production rates, and increased costs. These limitations have hindered the growth and scalability of the industry.2. Introduction of the Innovative Metal Forming Machine:Recognizing the need for a more efficient and streamlined manufacturing process, {} has developed a state-of-the-art metal forming machine. This technology integrates cutting-edge automation and precision engineering to facilitate the seamless production of IBR color steel rolls.3. Advanced Features and Capabilities:The newly developed machine boasts a range of advanced features that deliver exceptional performance and consistency. Its state-of-the-art control system enables precise adjustments of critical parameters, ensuring the production of consistently high-quality IBR color steel rolls. The machine also incorporates an intelligent material feeding system that optimizes material usage, minimizing waste and enhancing overall efficiency.4. Increased Production Efficiency:With the implementation of this innovative metal forming machine, the production efficiency of IBR color steel rolls is set to increase significantly. The automated processes eliminate manual errors and ensure consistent quality throughout the manufacturing process. The machine's high-speed operation enables faster production rates, meeting market demand swiftly and effectively.5. Enhanced Design Flexibility:The metal forming machine allows for greater design flexibility, enabling the production of IBR color steel rolls in various shapes, sizes, and colors. This flexibility has wide-ranging implications for diverse industries, such as construction, automotive, and manufacturing, as it enables the manufacture of customized steel rolls to meet specific project requirements.6. Cost-effectiveness and Sustainability:The advanced automation and optimization features of the metal forming machine contribute to cost reduction and sustainability. With reduced labor requirements and minimized material waste, manufacturers can achieve higher profitability while reducing their carbon footprint. This technological advancement aligns with the global industry's increasing focus on sustainable production practices.7. Market Impact and Future Prospects:The introduction of this groundbreaking metal forming machine is poised to revolutionize the IBR color steel roll manufacturing industry. Its ability to streamline production processes, improve quality, and increase design flexibility will positively impact market competitiveness and growth. Furthermore, it opens up new opportunities for steel roll manufacturers to explore a wider range of applications and cater to evolving customer requirements.Conclusion:The introduction of the advanced metal forming machine by {} promises to transform the steel roll manufacturing industry. Its cutting-edge features, enhanced efficiency, design flexibility, and sustainability aspects position it as a game-changer in the market. With this innovative technology at their disposal, manufacturers can drive growth, meet rising demands, and deliver superior quality IBR color steel rolls to various industries.

High-Quality Color Steel Roll Forming Machine for General Purpose Industrial Use

GP GI Color Steel Roll Forming Machine, a cutting-edge innovation in the field of manufacturing, is set to revolutionize the steel industry. This state-of-the-art machine, developed by an industry-leading company, is designed to enhance productivity, efficiency, and precision in the production of color steel products.The GP GI Color Steel Roll Forming Machine is the result of years of research and development by the company, which has a proven track record of delivering high-quality and reliable manufacturing solutions. With a focus on innovation and technological advancement, the company has positioned itself as a leader in the industry, continuously striving to push the boundaries of what is possible in steel production.The demand for color steel products, such as roofing and wall cladding materials, has been steadily increasing in recent years. This can be attributed to the growing construction industry, as well as the rising popularity of sustainable and aesthetically pleasing building materials. As a result, manufacturers are constantly seeking ways to improve their production processes to keep up with the market demand.The GP GI Color Steel Roll Forming Machine is set to address these industry challenges by offering a range of advanced features that set it apart from traditional roll forming machines. Equipped with cutting-edge technology, the machine is capable of producing high-quality color steel products with exceptional precision and efficiency. This is made possible by its innovative design, which incorporates the latest advancements in automation, material handling, and quality control.One of the key advantages of the GP GI Color Steel Roll Forming Machine is its ability to streamline the production process, thereby reducing lead times and increasing output. This is achieved through its high-speed forming capabilities, coupled with its intelligent control system that optimizes the manufacturing process. Additionally, the machine is designed to minimize material wastage, ensuring that manufacturers can maximize their resources while minimizing costs.Furthermore, the GP GI Color Steel Roll Forming Machine is highly adaptable, capable of producing a wide range of color steel products with different specifications and designs. This versatility is a significant advantage for manufacturers who need to meet diverse customer requirements, allowing them to quickly switch between product variations without the need for extensive retooling.In addition to its technical capabilities, the GP GI Color Steel Roll Forming Machine also prioritizes operator safety and ease of use. It is equipped with advanced safety features and user-friendly interfaces, ensuring that operators can work efficiently and without unnecessary risks. This not only improves the overall working environment but also contributes to consistent and reliable production outputs.The introduction of the GP GI Color Steel Roll Forming Machine is a testament to the company's commitment to driving innovation and excellence in the steel manufacturing industry. By leveraging its expertise and technological capabilities, the company has developed a machine that is set to redefine the standards of quality and efficiency in color steel production.As the global demand for color steel products continues to grow, the GP GI Color Steel Roll Forming Machine is poised to become an indispensable asset for manufacturers looking to stay ahead of the competition. With its combination of cutting-edge technology, versatility, and user-centric design, this machine is set to make a significant impact on the industry, setting new benchmarks for productivity and performance.

Enhanced Efficiency and Easy Maintenance: Revolutionary Roll Forming Machine for Steel Roofing

Title: Color Steel Roofing Roll Forming Machine: Revolutionizing Steel Roofing ProductionIntroduction: In the fast-paced construction industry, time and efficiency are crucial factors for success. The advent of roll forming machines has revolutionized the production of color steel roofing, offering enhanced automation, streamlined processes, and remarkable output quality. This blog post aims to shed light on the advancements in the roll forming machine technology and the myriad benefits it offers in the production of color steel roofing. Read on to learn more!Section 1: Understanding the Roll Forming MachineRoll forming machines have become the backbone of the steel roofing industry, thanks to their unmatched ability to produce high-quality steel roofing panels at an impressive speed. These machines utilize advanced automatic control software to manage production information effectively and optimize overall performance. The integration of a highly efficient network further enhances automation, enabling seamless coordination among different components.Section 2: Advantages of the Color Steel Roofing Roll Forming Machine2.1 Improved Automation: The color steel tile equipment boasts a fully automated control system that simplifies operation, maintenance, maintenance, mechanical debugging, and mold replacement. The combination of high-level control software and an integrated network enables the machine to perform at its best, reducing the need for manual intervention and enhancing productivity.2.2 Enhanced Efficiency: With its advanced technology and automatic control capabilities, the roll forming machine eliminates time-consuming processes, such as manual measurements and adjustments. This translates into faster production cycles and increased efficiency, enabling manufacturers to meet tight deadlines and fulfill customer demands promptly.2.3 Superior Product Quality: The precision and accuracy offered by a color steel roofing roll forming machine ensure consistent and high-quality output. The machine guarantees precise bending, cutting, and forming of steel panels, minimizing errors and deviations. With its ability to maintain uniformity throughout the production line, the roll forming machine delivers products of superior strength, durability, and aesthetics.Section 3: Key Features of the Color Steel Roofing Roll Forming Machine3.1 Customizability: A major advantage of roll forming machines is their ability to accommodate various design requirements. Manufacturers can easily adapt the machine to produce different profiles, sizes, and thicknesses of color steel roofing panels. This flexibility allows for greater creativity, enabling builders and architects to explore unique roofing designs.3.2 Ease of Operation: The roll forming machine is designed to simplify the production process and minimize the need for technical expertise. Its user-friendly interface and intuitive controls enable operators to quickly understand and manage the machine's operation. Additionally, mold replacement is a hassle-free process, saving time and effort.3.3 Low Maintenance: Roll forming machines are engineered for durability and reliability, ensuring minimal maintenance requirements. The incorporation of robust components and modern technologies minimizes wear and tear, thereby reducing downtime and increasing overall equipment lifespan.Section 4: Incorporating Color Steel Roofing Roll Forming Machines in Construction ProjectsColor steel roofing panels produced by roll forming machines find extensive applications in commercial, residential, and industrial construction. Their versatility, durability, and visual appeal make them a popular choice among architects, builders, and homeowners alike. The high-speed production capabilities of roll forming machines allow for quick and efficient completion of projects, making them ideal for meeting strict construction timelines.Conclusion:The roll forming machine has transformed the steel roofing industry by introducing automation, advanced control systems, and efficiency-enhancing features. With their ability to produce high-quality color steel roofing panels at an impressive speed, these machines have become an indispensable asset for manufacturers in the construction sector. As the demand for superior quality and efficient production continues to grow, roll forming machines will undoubtedly remain at the forefront of steel roofing manufacturing processes.

Efficient and Durable Steel Sheet Roll Forming Machine for Colorful Structures

Title: Cutting-Edge Color Steel Sheet Roll Forming Machine Revolutionizes the Construction IndustryIntroduction:In an era defined by technological advancements, the construction industry is not exempt from the benefits of innovation. One such game-changer is the Color Steel Sheet Roll Forming Machine, a state-of-the-art piece of equipment that has the potential to transform the way steel sheets are manufactured for construction purposes. Developed by a leading manufacturer in the sector, this machine promises greater efficiency, precision, and cost-effectiveness in the production process. With key features tailored to meet the evolving demands of the construction industry, this groundbreaking equipment represents a significant leap forward in metal sheet roll forming technology.Unveiling the Color Steel Sheet Roll Forming Machine:Designed to meet the growing demand for quality color steel sheet products, the Color Steel Sheet Roll Forming Machine seamlessly combines cutting-edge technology, durability, and versatility. It boasts an innovative roll forming system that ensures the precise shaping of steel sheets while maintaining exceptional dimensional accuracy. The machine is equipped with a host of advanced features that reduce production time and costs while significantly improving the overall product quality.Key Features and Advantages:1. High Precision: The machine utilizes advanced algorithms and computer-controlled systems, enabling it to deliver unmatched precision in the roll forming process. This precision ensures consistent product quality, precise dimensions, and greater compatibility with other construction materials.2. Enhanced Efficiency: The Color Steel Sheet Roll Forming Machine integrates automated processes, including coil loading, sheet preheating, roll forming, cutting, and stacking. These automated operations minimize manual intervention, resulting in faster and more efficient production. Increased productivity translates into reduced labor costs and shorter project timelines.3. Versatility: With customizable settings, the machine can adapt to different color steel sheet profiles, weights, and thicknesses. This flexibility allows manufacturers to cater to a wide range of construction applications, accommodating various architectural designs and structural requirements.4. Material Optimization: The machine's intelligent controls optimize the amount of raw material used, minimizing waste and reducing production costs. This eco-friendly approach benefits both manufacturers and the environment, making the Color Steel Sheet Roll Forming Machine a sustainable choice for the construction industry.5. User-Friendly Interface: The machine is equipped with a user-friendly interface, featuring an intuitive control panel that requires minimal training. This user-friendly design ensures that even less experienced operators can operate the machine with ease, reducing the risk of errors and improving overall productivity.Impact on the Construction Industry:The introduction of this advanced Color Steel Sheet Roll Forming Machine offers significant benefits to the construction industry. Firstly, it reduces manufacturing costs, enabling construction companies to lower their project budgets without compromising quality. Secondly, the increased precision and efficiency streamline the construction process, enabling faster project completion and improved customer satisfaction. Additionally, the machine's versatility allows for greater architectural freedom, enabling designers to explore innovative building concepts using color steel sheets.Conclusion:The unveiling of the Color Steel Sheet Roll Forming Machine marks a significant milestone in the construction industry and facilitates increased efficiency, precision, and cost-effectiveness in the manufacturing process of color steel sheets. With its innovative features and unmatched versatility, this cutting-edge equipment promises to revolutionize the construction sector by enhancing productivity and reducing production costs. As the demand for sustainable and high-quality construction materials continues to grow, this advanced technology provides an ideal solution for meeting these evolving industry needs.