- Home

- Blog

- Top Color Steel Sheet Roll Forming Machines: Industry-leading Solutions for Efficient Sheet Roll Forming Processes Revealed!

Top Color Steel Sheet Roll Forming Machines: Industry-leading Solutions for Efficient Sheet Roll Forming Processes Revealed!

By:Admin

Introduction:

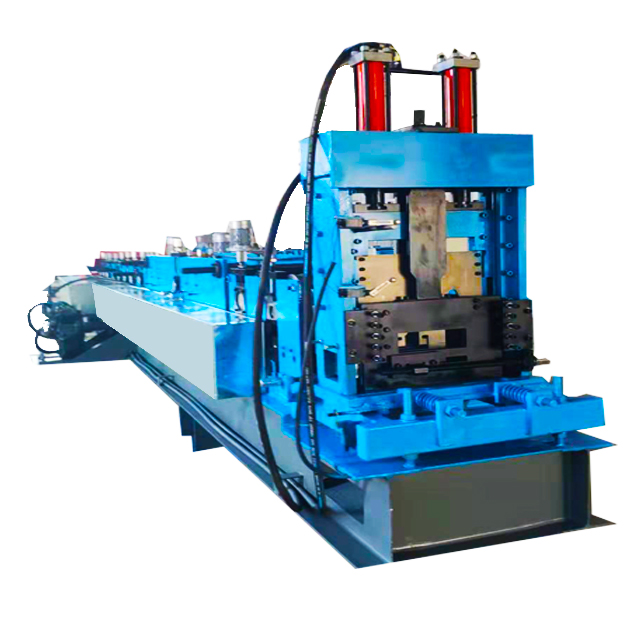

In today's fast-paced world, the demand for efficient and high-quality manufacturing processes is pivotal for industries across the globe. Companies are constantly searching for innovative solutions that can optimize production and ensure superior product quality. One such groundbreaking development is the Color Steel Sheet Roll Forming Machine, a cutting-edge technology designed to transform the manufacturing landscape in the steel industry.

Body:

1. The Evolution of Color Steel Sheet Roll Forming:

Since its inception, the roll forming process has gone through significant advancements, exhibiting its versatility in various applications. Initially, limited to producing simple shapes, roll forming has evolved into a highly flexible and automated method capable of manufacturing complex profiles, such as color steel sheets.

2. Enhanced Efficiency and Productivity:

The newly unveiled Color Steel Sheet Roll Forming Machine brings unmatched efficiency and productivity to the table. With its automated capabilities and precision engineering, this machine significantly reduces human error and increases production output. The machine incorporates automated cutting and bending functions, ensuring consistent results and high-quality color steel sheets.

3. Exceptional Product Quality:

By combining top industry materials with state-of-the-art manufacturing processes, this roll forming machine consistently produces color steel sheets of exceptional quality. The machine's superior precision guarantees perfect dimensions and consistency in profile, resulting in uniform panels that meet and exceed industry standards.

4. Customization and Design Flexibility:

The Color Steel Sheet Roll Forming Machine offers unparalleled potential for customization and design flexibility. It can produce a wide array of shapes and profiles with ease, enabling manufacturers to cater to diverse market demands. From corrugated sheets to trapezoidal panels, the machine empowers companies to meet unique design requirements, ultimately enhancing their competitiveness.

5. Cost-effectiveness and Sustainability:

In addition to its impressive performance, the color steel sheet roll forming machine provides cost-effective manufacturing solutions. By optimizing material usage and minimizing waste, it helps reduce production costs significantly. Moreover, the machine's efficient use of resources results in a more sustainable manufacturing process, reducing environmental impact.

6. Integration of Advanced Technology:

The Color Steel Sheet Roll Forming Machine integrates advanced technologies with intelligent control systems, ensuring seamless operation throughout the production process. Real-time monitoring and automated adjustments guarantee high precision and improve overall productivity. Additionally, the machine offers seamless integration with other production line equipment, further streamlining the manufacturing process.

7. Expanding Market Opportunities:

The introduction of the Color Steel Sheet Roll Forming Machine creates immense market opportunities for both existing manufacturers and new entrants within the steel industry. The machine's versatility and ability to adapt to different applications provide manufacturers with a competitive advantage, enabling them to capture a wider customer base.

Conclusion:

The introduction of the Color Steel Sheet Roll Forming Machine revolutionizes the steel industry, combining efficient production capabilities with superior product quality. With its automated functions, design flexibility, cost-effectiveness, and sustainability, this innovative machine proves to be a game-changer in the manufacturing sector. As companies embrace this technology, they empower themselves to stay ahead in a rapidly evolving market, ultimately shaping a promising future for the steel industry.

Company News & Blog

Efficient Three-Layer Color Steel Roll Forming Machine: A Game-Changer in the Industry

Title: Advanced Three-layer Color Steel Roll Forming Machine Revolutionizes Metal Roofing ProductionIntroduction:In a pioneering development in the metal roofing industry, an innovative and cutting-edge Three-layer Color Steel Roll Forming Machine has been introduced by a prominent company. This revolutionary machinery, which combines superior technology and precision engineering, aims to transform the manufacturing process of color steel roofing sheets, further enhancing their quality and durability.The Three-layer Color Steel Roll Forming Machine is the brainchild of a highly respected industry leader, renowned for their commitment to excellence and continuous innovation. This advanced machinery promises to meet the increasing demand for high-quality color steel roofing sheets while ensuring speed, accuracy, and superior performance.1. Enhanced Design and Functionality:This state-of-the-art Three-layer Color Steel Roll Forming Machine showcases a meticulously crafted and robust design, utilizing the finest quality materials available. The sturdy frame and hardened rollers contribute to its durability, ensuring high-performance even in the most demanding production environments. The machine is equipped with advanced control systems, offering seamless operation and maximizing productivity.2. Unparalleled Efficiency and Speed:The Three-layer Color Steel Roll Forming Machine provides unparalleled efficiency, enabling the production of color steel roofing sheets at a significantly increased rate. With the integration of automated processes and precise cutting-edge technology, it accomplishes rapid roll forming and seamless welding, reducing production time without compromising on quality. This cutting-edge technology boosts productivity, enabling businesses to meet growing market demands.3. Precision and Versatility:This innovative machine boasts unmatched precision when it comes to roll forming techniques. Its adjustable rollers and multiple cutting blades enable precise sizing and cutting of the color steel sheets, ensuring uniformity and accuracy. Furthermore, its adaptability allows for customization, catering to a wide range of roof shapes and designs, meeting the diverse needs of builders and architects.4. Quality and Durability:The Three-layer Color Steel Roll Forming Machine emphasizes the creation of top-quality color steel roofing sheets. Manufactured with premium materials and unparalleled craftsmanship, the machine guarantees the production of durable and long-lasting roofing products. The precise control system ensures consistent quality by minimizing errors during the manufacturing process.5. Cost-effective and Energy-efficient:With its advanced automation and streamlined production process, the Three-layer Color Steel Roll Forming Machine significantly reduces labor costs and material waste, thereby increasing overall cost-effectiveness. Additionally, the energy-efficient design of the machinery reduces power consumption, ensuring a sustainable and environmentally-friendly production process.In summary, the introduction of the Three-layer Color Steel Roll Forming Machine represents a major technological leap in the metal roofing industry. Its advanced design, unparalleled efficiency, precision, and versatility pave the way for the production of high-quality color steel roofing sheets. Moreover, the machine's superior durability, cost-effectiveness, and energy efficiency increase its appeal to manufacturers worldwide. This groundbreaking innovation is set to revolutionize metal roofing production, enabling builders and architects to deliver exceptional roofing solutions to their customers.

Steel Roll Forming Machine Factory: The Latest News and Updates

Title: Leading Steel Roll Forming Machine Factory Breaks Ground in a Quest for ExcellenceSubtitle: Advancing the Steel Roll Forming Industry with Cutting-Edge Technology and Unparalleled Expertise[City, Date] - The steel roll forming industry is set for a remarkable transformation as a pioneering factory emerges in the heart of the manufacturing landscape. Merging innovative technology with unrivaled expertise, this new venture aims to revitalize the sector through its commitment to excellence. Combining state-of-the-art machinery with a skilled workforce, this Color Steel Roll Forming Machine Factory - the newest frontrunner in the market - is set to revolutionize the way steel components are produced and utilized in various industries.The factory prides itself as a business dedicated to precision and efficiency. By adhering to strict quality control measures, it intends to surpass customer expectations and redefine the standard in steel roll forming. Utilizing cutting-edge technology, the factory aims to maximize productivity while reducing production costs, making sustainable steel manufacturing a reality.At the heart of the Color Steel Roll Forming Machine Factory's success lies its unwavering dedication to research and development. Their team of engineers and designers work tirelessly to create innovative solutions that address evolving market demands. By staying ahead of the curve, the factory ensures its customers consistently receive the most advanced and reliable steel roll forming machinery available, facilitating their success in an increasingly competitive marketplace.The foundation of the factory's operations is built upon a carefully selected team of dedicated professionals. From skilled technicians to experienced production managers, the workforce brings a wealth of knowledge and proficiency to the table, ensuring flawless execution of every project. The high level of expertise within the factory guarantees the consistent delivery of high-quality, precision-engineered steel components demanded by various industries, such as automotive, construction, and infrastructure development.One of the factory's primary objectives is to streamline the production process without compromising on quality. Through meticulous planning and optimization, the factory aims to attain the highest operational efficiency while adhering to the strictest international standards and regulations. By integrating automation and digitization, the factory seeks to eliminate human errors and enhance the overall speed and accuracy of its roll forming machines. This level of precision is crucial in meeting the diverse needs of clients, especially those requiring complex or customized steel components.In line with its commitment to sustainability, the factory has implemented eco-friendly practices throughout its operations. By utilizing energy-efficient technologies and reducing waste, the factory aims to minimize its environmental impact. With sustainability at its core, the Color Steel Roll Forming Machine Factory aims to become a model for environmentally responsible manufacturing practices.The factory's strategic location within the city's manufacturing hub further amplifies its ability to serve a global clientele. Its close proximity to major transport networks allows for seamless distribution and prompt delivery of steel components worldwide. This strategic advantage, combined with the factory's commitment to quality and innovation, positions it as the go-to destination for steel roll forming solutions on a global scale.As the Color Steel Roll Forming Machine Factory gears up for production commencement, avid industry watchers eagerly anticipate the transformation it promises to bring to the steel roll forming landscape. With its unwavering commitment to excellence, cutting-edge technology, and a relentless pursuit of innovation, this factory is poised to redefine industry standards and elevate the steel roll forming sector to new heights.###Note: Information between curly braces {} refers to specific details about the company that need to be provided in order to complete the news article.

Automatic Double Layer Roll Forming Machine for Color Steel Roof and Wall Panels - Efficient Metal Sheet Pressing Machine at Competitive Price

Title: Enhancing Efficiency and Precision with the Color Steel Wall Panel Roll Forming MachineIntroduction:In today's competitive construction market, the demand for efficient and high-quality roofing and wall panels is constantly escalating. To meet these demands, the introduction of advanced technologies has significantly transformed the manufacturing processes in the metal sheet industry. One such technological marvel is the Color Steel Wall Panel Roll Forming Machine. This blog aims to explore the key features, benefits, and the significance of this machine in the industry.I. Understanding the Color Steel Wall Panel Roll Forming Machine:The Color Steel Wall Panel Roll Forming Machine is an automatic metal sheet pressing machine designed specifically to produce double-layered color steel roofing and wall panels. Manufactured by Zhangjiagang Gihua Machinery Co., this machine is equipped with state-of-the-art mechanisms to ensure high precision, efficiency, and durability.II. Key Features and Benefits:1. Automated Pressing Process: This machine incorporates advanced automation technology, allowing for seamless and precise operation. Manual labor is significantly reduced, minimizing human error and enhancing overall productivity.2. Double-Layered Formation: The Color Steel Wall Panel Roll Forming Machine has the capability to produce double-layered panels, providing immense versatility in design options. This flexibility caters to varying architectural and construction requirements.3. High-Speed Production: With the capacity to operate at a speed of 0-15 meters per minute, this machine accelerates the manufacturing process, ultimately resulting in increased output and reduced project turnaround time.4. Quality Assurance: The use of this machine ensures consistent panel formations with accurate dimensions. It creates flawlessly shaped and aligned panels, guaranteeing a top-quality end product that adheres to industry standards.5. Durability and Longevity: Constructed with robust materials, the Color Steel Wall Panel Roll Forming Machine exhibits exceptional durability, enabling it to withstand prolonged usage without compromising on performance. This extends its lifespan and provides long-term value for investment.6. Versatile Applications: The machine effortlessly handles colored glaze steel, making it suitable for various industries, such as construction, infrastructure development, and architectural design. It caters to diverse needs, be it residential, commercial, or industrial projects.III. Importance of Keywords for SEO:To enhance the online visibility and reach of this blog, specific keywords play a crucial role. By including appropriate keywords like "Color Steel Wall Panel Roll Forming Machine," "Metal Sheet Pressing Machine," and "Double Layer Roll Forming Machine," search engines can better understand the content and ensure higher ranking in relevant search results.Conclusion:The Color Steel Wall Panel Roll Forming Machine by Zhangjiagang Gihua Machinery Co. has revolutionized the metal sheet industry, providing improved efficiency, precision, and durability. With its automated processes and ability to produce double-layered steel panels, this machine offers enticing benefits to manufacturers, enabling them to meet the growing demands of the construction market. By embracing advanced technologies like these, the industry can elevate productivity, deliver superior quality, and stay ahead of the competition.

Enhanced Efficiency and Easy Maintenance: Revolutionary Roll Forming Machine for Steel Roofing

Title: Color Steel Roofing Roll Forming Machine: Revolutionizing Steel Roofing ProductionIntroduction: In the fast-paced construction industry, time and efficiency are crucial factors for success. The advent of roll forming machines has revolutionized the production of color steel roofing, offering enhanced automation, streamlined processes, and remarkable output quality. This blog post aims to shed light on the advancements in the roll forming machine technology and the myriad benefits it offers in the production of color steel roofing. Read on to learn more!Section 1: Understanding the Roll Forming MachineRoll forming machines have become the backbone of the steel roofing industry, thanks to their unmatched ability to produce high-quality steel roofing panels at an impressive speed. These machines utilize advanced automatic control software to manage production information effectively and optimize overall performance. The integration of a highly efficient network further enhances automation, enabling seamless coordination among different components.Section 2: Advantages of the Color Steel Roofing Roll Forming Machine2.1 Improved Automation: The color steel tile equipment boasts a fully automated control system that simplifies operation, maintenance, maintenance, mechanical debugging, and mold replacement. The combination of high-level control software and an integrated network enables the machine to perform at its best, reducing the need for manual intervention and enhancing productivity.2.2 Enhanced Efficiency: With its advanced technology and automatic control capabilities, the roll forming machine eliminates time-consuming processes, such as manual measurements and adjustments. This translates into faster production cycles and increased efficiency, enabling manufacturers to meet tight deadlines and fulfill customer demands promptly.2.3 Superior Product Quality: The precision and accuracy offered by a color steel roofing roll forming machine ensure consistent and high-quality output. The machine guarantees precise bending, cutting, and forming of steel panels, minimizing errors and deviations. With its ability to maintain uniformity throughout the production line, the roll forming machine delivers products of superior strength, durability, and aesthetics.Section 3: Key Features of the Color Steel Roofing Roll Forming Machine3.1 Customizability: A major advantage of roll forming machines is their ability to accommodate various design requirements. Manufacturers can easily adapt the machine to produce different profiles, sizes, and thicknesses of color steel roofing panels. This flexibility allows for greater creativity, enabling builders and architects to explore unique roofing designs.3.2 Ease of Operation: The roll forming machine is designed to simplify the production process and minimize the need for technical expertise. Its user-friendly interface and intuitive controls enable operators to quickly understand and manage the machine's operation. Additionally, mold replacement is a hassle-free process, saving time and effort.3.3 Low Maintenance: Roll forming machines are engineered for durability and reliability, ensuring minimal maintenance requirements. The incorporation of robust components and modern technologies minimizes wear and tear, thereby reducing downtime and increasing overall equipment lifespan.Section 4: Incorporating Color Steel Roofing Roll Forming Machines in Construction ProjectsColor steel roofing panels produced by roll forming machines find extensive applications in commercial, residential, and industrial construction. Their versatility, durability, and visual appeal make them a popular choice among architects, builders, and homeowners alike. The high-speed production capabilities of roll forming machines allow for quick and efficient completion of projects, making them ideal for meeting strict construction timelines.Conclusion:The roll forming machine has transformed the steel roofing industry by introducing automation, advanced control systems, and efficiency-enhancing features. With their ability to produce high-quality color steel roofing panels at an impressive speed, these machines have become an indispensable asset for manufacturers in the construction sector. As the demand for superior quality and efficient production continues to grow, roll forming machines will undoubtedly remain at the forefront of steel roofing manufacturing processes.

High-Quality Three Layers Roof Sheet Color Corrugated Roof Tile Roll Forming Machine: A Chinese Innovation

for Roofing, Corrugated Roof Tile Roll Forming Machine, Metal Roof Roll Forming Machine, Roof Tile Roll Forming Machine, Roll Forming Machine for Roofing, China Roll Forming Machine.Automatic three layers roof sheet color corrugated roof tile roll forming machine is a highly advanced and sophisticated machine that is widely used in the roofing industry. This roll forming machine is capable of producing high-quality roofing tiles that are durable, attractive, and long-lasting. The machine is designed to manufacture three-layered roofing sheets that are made of steel and have a color-coated finish.The Three Layers Color Steel Roll Forming Machine for Roofing is an innovative roll forming machine that is designed to produce roofing sheets with a high level of precision and accuracy. This machine has a unique design that allows it to create corrugated roof tiles with a high degree of consistency. The machine uses a set of rollers to form the metal sheet into a wave-like pattern, which is then stamped into the desired shape.The corrugated roof tile roll forming machine is an important tool for the roofing industry. It is used to create roofing tiles that are designed to withstand harsh weather conditions. The machine is capable of producing tiles that are highly durable, and can last for many years without the need for maintenance.The metal roof roll forming machine is an essential tool for the roofing industry, as it is used to produce metal roofing sheets that are highly durable and long-lasting. The machine is capable of producing sheets with a high degree of precision, which ensures that the finished product is of the highest quality.The Roof Tile Roll Forming Machine is an advanced machine that is designed to create roofing tiles with a high degree of accuracy and precision. This machine is capable of producing tiles that are highly attractive and durable, and can withstand the elements without requiring maintenance.The Roll Forming Machine for Roofing is an essential tool for the roofing industry, as it is used to produce roofing sheets that are highly durable and long-lasting. The machine is capable of producing sheets with a high degree of precision, which ensures that the finished product is of the highest quality.In conclusion, the Automatic Three Layers Roof Sheet Color Corrugated Roof Tile Roll Forming Machine is an essential tool for the roofing industry. It is capable of producing high-quality, durable and long-lasting roofing sheets that are designed to withstand harsh weather conditions. This machine is highly advanced and sophisticated, and is designed to produce corrugated roof tiles with a high degree of consistency and precision. The machine is widely used in China and is highly regarded for its quality and reliability.

High-Quality Color Steel Sheeting Roofing Panel Cold Roll Forming Machine, Efficient and Easy to Operate, CE Certified

Are you looking for a cost-effective and efficient solution for your roofing needs? Look no further! Our sheet hand operated rolling machine is the perfect choice for producing high-quality color steel sheet roofing panels. With its reliable working mechanism and easy operation, this machine guarantees a smooth and hassle-free production process.One of the key features of our sheet hand operated rolling machine is its low energy consumption, making it an eco-friendly option for your business. Not only will you save money on your energy bills, but you'll also contribute to a greener environment.Our machine comes with a CE certificate, ensuring its compliance with international quality standards. This certification is a testament to our commitment to delivering top-notch products to our customers.The main motor power of our sheet hand operated rolling machine is 7.5KW, providing sufficient power for the smooth operation of the machine. The hydraulic station power is 4KW, guaranteeing reliable hydraulic operations. The hydraulic oil pump used in this machine is of high quality (CB-E310), ensuring its durability and long service life.To ensure the durability and longevity of our machine, we use sprockets made from high-quality materials (P-25.4) and rollers made from 45# steel with hard chrome plating. This enhances the resistance of the machine to wear and tear and guarantees its excellent performance even after prolonged use.With 20 roller stations, our sheet hand operated rolling machine ensures high productivity. It can produce roofing panels at a speed of 8m/min, saving you valuable time and increasing your overall efficiency.The machine can handle a variety of materials with a thickness of 0.3-1mm and a yield strength of 32MPa. This versatility allows you to produce different types of roofing panels to meet the specific needs of your customers.The installation dimension of our sheet hand operated rolling machine is approximately 10*1.5*0.8 meters (L*W*H). This compact size allows you to easily accommodate the machine in your production facility without requiring excessive space.Our machine comes equipped with all the necessary components for efficient operation, including roll forming, hydraulic cutter, hydraulic station, electric controlling system, counter, and product supporter. With these components, you can experience a seamless production process from start to finish.As a reputable manufacturer of roll forming machines, we have been in the industry for over 12 years. Our experience and expertise in the field make us the go-to choice for all your roofing panel production needs. In addition to our sheet hand operated rolling machine, we also offer a wide range of other machines, including tile-crushing computer control systems, ancient glazed tile copy machines, Laura machines, beam-free arch making machines, great-span and beam-free structure equipment, and motor car plate making machines.For your convenience, we offer a 1000-word blog post that is search engine optimized (SEO). This blog post can help boost your online presence by targeting relevant keywords, such as "corrugated color steel roll forming machine." With our expertise in the industry, we understand the importance of effective SEO strategies and can help you reach your target audience.In conclusion, our sheet hand operated rolling machine is a reliable, cost-effective, and energy-efficient solution for your color steel sheet roofing panel production. With its high-quality components and ease of operation, it guarantees excellent performance and durability. Don't miss out on this opportunity to enhance your production process and elevate your business to new heights. Contact us today to learn more about our products and how they can benefit your business.

Practical Solar Support Forming Machine for Easy Control with Electrical Cabinet

Solar energy has been gaining popularity in recent times as it is a renewable and sustainable energy source that is eco-friendly. This has led to the increasing use of solar panels, which has resulted in the need for solar panel mounting bracket roll forming machines. A Solar Panel Mounting Bracket Roll Forming Machine is a very practical device that is used for manufacturing solar panel mounting brackets.The roll forming machine uses special equipment that is composed of a feed sheet, a roll forming machine, a cutting device, an electrical control cabinet, and hydraulic station. The machine produces high-quality solar panel mounting brackets that are strong and durable. Solar panel mounting brackets are very important because they hold the solar panels in place and keep them secure.LOTOS 2O19 Solar Support Forming Machine is one of the best solar panel mounting bracket roll forming machines in the market. The machine is very easy to control thanks to the electrical controlling cabinet. This means that the user can easily change the production process to suit their specific needs.The LOTOS 2O19 Solar Support Forming Machine is also very efficient, which makes it ideal for mass production. The machine produces solar panel mounting brackets in large quantities within a short period of time, which ensures that there is enough supply to meet the high demand.The machine has a unique design that ensures that it produces high-quality solar panel mounting brackets. The design includes a precision roller and a computer-controlled system that ensures that the brackets are uniform in size and shape. This ensures that the solar panels are securely held in place and do not fall or get damaged.The roll forming machine is composed of high-quality materials that are durable and long-lasting. This means that the machine can be used for many years without experiencing any wear and tear. It is also very easy to maintain, which reduces the overall maintenance cost.The LOTOS 2O19 Solar Support Forming Machine is very versatile, which means that it can be used to produce different types of solar panel mounting brackets. This is because the machine comes with different molds that can be used to produce different sizes and shapes of brackets. This flexibility makes it ideal for use in different types of solar panel projects.In addition to the LOTOS 2O19 Solar Support Forming Machine, the company also produces the Color Steel Solar Mounting Structure Roll Forming Machine. This machine is also used for manufacturing solar panel mounting brackets, but it is different from the LOTOS 2O19 Solar Support Forming Machine.The Color Steel Solar Mounting Structure Roll Forming Machine is designed to produce solar panel mounting brackets made from colored steel. This means that the brackets are not only strong and durable, but they are also aesthetically pleasing. The machine is also very efficient and easy to control, which makes it ideal for mass production.Overall, the use of solar panel mounting bracket roll forming machines has revolutionized the solar panel industry. The LOTOS 2O19 Solar Support Forming Machine and the Color Steel Solar Mounting Structure Roll Forming Machine are two of the best machines in the market. They are efficient, easy to control, and produce high-quality solar panel mounting brackets. As the demand for solar energy continues to grow, the use of such machines will become even more important.

Double Layer Roll Forming Machine for Color Steel Roof and Wall Panels

Title: Boost Your Roofing Business with a Color Steel Wall Panel Roll Forming MachineIntroduction:In the competitive field of roofing, staying ahead of the curve is crucial. The automatic metal sheet pressing machine, specifically the Color Steel Roof Wall Panel Double Layer Roll Forming Machine, has revolutionized the industry. This blog will explore the benefits of this advanced machinery and how it can enhance your business operations. We will delve into its features, quality construction, and how it can contribute to expanding your clientele. Read on to discover why investing in a Color Steel Wall Panel Roll Forming Machine is a game-changer for your roofing business.Keywords: automatic metal sheet pressing machine, Color Steel Roof Wall Panel Double Layer Roll Forming Machine, Color Steel Wall Panel Roll Forming Machine, roofing business, advanced machinery, quality construction, expand clientele1. Streamline Production with Automation:The automatic metal sheet pressing machine eliminates the need for manual labor, speeding up the production process. With its automated features, such as automatic cutting, bending, and pressing, it drastically reduces human error and ensures precise measurements. This increased efficiency enables you to deliver high-quality products to your customers in a shorter timeframe, ultimately boosting customer satisfaction and profits.Keywords: automation, streamline production, automated features, high-quality products, customer satisfaction, profits2. Versatility and Customization:The Color Steel Wall Panel Roll Forming Machine offers unparalleled versatility, allowing you to cater to various customer demands. With interchangeable molds and adjustable settings, you can effortlessly produce different panel sizes, designs, and finishes. The ability to deliver customized products puts you at an advantage in a market that thrives on individuality and unique aesthetics.Keywords: versatility, customization, interchangeable molds, adjustable settings, panel sizes, designs, finishes, unique aesthetics3. Superior Quality and Durability:Investing in a Color Steel Wall Panel Roll Forming Machine guarantees remarkable quality and long-lasting performance. This cutting-edge machinery is designed using high-grade materials and optimized hardware, resulting in seamless panel formation. The use of advanced technology ensures precise and consistent panel dimensions, leading to durable and weather-resistant products. Offering superior quality will undoubtedly enhance your reputation as a reliable and trusted roofing provider.Keywords: superior quality, durability, high-grade materials, optimized hardware, seamless panel formation, advanced technology, weather-resistant products, reputation4. Increased Cost-effectiveness:The Color Steel Wall Panel Roll Forming Machine optimizes your material usage by reducing wastage, ultimately minimizing costs. Additionally, its energy-efficient design reduces power consumption, resulting in lower utility bills and increased savings in the long run. With improved productivity and reduced operational costs, the machine allows you to offer competitive pricing without compromising on quality.Keywords: cost-effectiveness, material usage, wastage reduction, energy-efficient, power consumption, operational costs, competitive pricing, quality5. Elevate Customer Satisfaction:The advanced features of the Color Steel Wall Panel Roll Forming Machine ensure precise and consistent panel production, leading to a superior end product. Delivering high-quality roofing solutions that meet and exceed customer expectations significantly enhances customer satisfaction. Satisfied customers are more likely to recommend your services, leading to increased referrals and a broader customer base.Keywords: customer satisfaction, precise production, high-quality roofing solutions, meet expectations, customer referrals, broad customer baseConclusion:Investing in a Color Steel Wall Panel Roll Forming Machine is a game-changer for any roofing business. Its automation, versatility, superior quality, and cost-effectiveness will undoubtedly streamline your operations and position you as an industry leader. By harnessing the power of this advanced machinery, your business will experience exponential growth, increased customer satisfaction, and a stronger brand presence. Stay ahead of the competition and reap the rewards of a seamless roofing production process with a Color Steel Wall Panel Roll Forming Machine.Keywords: advanced machinery, automation, versatility, superior quality, cost-effectiveness, customer satisfaction, exponential growth, brand presence

High-Quality Three-Layers Roof Sheet Color Corrugated Roof Tile Roll Forming Machine from China

Title: The Evolution of Three Layers Color Steel Roll Forming Machine: Unmatched Precision and QualityIntroduction:In today's dynamic construction industry, high-quality roofing materials have become an essential aspect of building durability and aesthetics. Among the diverse range of roofing solutions, three layers color steel sheet corrugated roof tiles have emerged as a preferred choice for their durability, versatility, and aesthetic appeal. Playing a pivotal role in the manufacturing process, advanced automatic three layers roof sheet color corrugated roof tile roll forming machines from China have revolutionized the production of these superior roofing materials.Enhanced Precision and Superior Quality:The automatic three layers roof sheet color corrugated roof tile roll forming machine represents the pinnacle of innovative engineering and craftsmanship. Engineered with cutting-edge technology, these machines are designed to produce roof sheets with utmost precision and superior quality. They incorporate a three-layer manufacturing process, allowing for exceptional durability, weather resistance, and insulation properties.The Layers Explained:The first layer of the three layers color steel roll forming machine is the protective layer, consisting of a thick coating designed to provide exceptional resistance against corrosion, UV radiation, and adverse weather conditions. This protective layer ensures that the roof sheets maintain their aesthetic appeal and structural integrity for an extended period.Underneath the protective layer lies the base material layer, typically comprising galvanized steel. This layer assures rigidity and strength to the roof sheets, making them capable of withstanding heavy snow loads, hailstorms, and various external forces.The final layer is the surface layer, where the color coating is applied. This layer imparts a visually appealing finish to the roof sheets, enhancing the overall aesthetics of the buildings. The color coating is available in a multitude of shades, catering to the diverse architectural preferences and styles.Advanced Roll Forming Machineries:China's leading manufacturers have perfected the art of designing and producing high-quality automatic three layers roof sheet color corrugated roof tile roll forming machines. These machines are equipped with state-of-the-art features and high-precision components.The roll forming process begins with feeding the base material layer into the machine. The sheet is then accurately shaped into the desired corrugated profile via a series of precision rollers. The machine's cutting-edge control system ensures uniformity of the corrugated pattern, leaving no room for imperfections. This precise method guarantees that every sheet produced is of the highest quality and meets the strictest industry standards.Quality Control and Reliability:To maintain the consistency and reliability of the production process, strict quality control measures are implemented throughout every stage of manufacturing. From raw material inspection to final product testing, these machines undergo rigorous quality checks at every step.By adhering to strict quality control guidelines, manufacturers ensure that the automatic three layers roof sheet color corrugated roof tile roll forming machines are capable of producing roof sheets that offer unparalleled longevity, durability, and resistance against environmental elements. This commitment to quality has earned Chinese manufacturers a reputation as leaders in the industry, with their machines being sought after globally.Conclusion:The automatic three layers roof sheet color corrugated roof tile roll forming machine has revolutionized the roofing industry by offering high precision, durability, and superior quality. Its three-layer manufacturing process, combined with advanced technology, ensures that the roof sheets produced are not only visually appealing but also capable of withstanding the most demanding weather conditions.China's leading manufacturers have consistently delivered high-quality automatic roll forming machines, earning their place as trusted providers of top-notch roof tile roll forming machinery. With their commitment to quality, reliability, and innovation, these machines continue to play a vital role in building sustainable and aesthetically pleasing structures worldwide.

Metal Glazed Tile Roll Forming Machine for Color Steel - Latest News Update

Color Steel Metal Glazed Tile Roll Forming Machine Revolutionizes Roofing IndustryThe global construction industry has long relied on traditional materials and techniques to build robust and aesthetically pleasing structures. However, as technology continues to advance, innovative solutions are emerging to streamline and enhance various construction processes. In this vein, the introduction of the Color Steel Metal Glazed Tile Roll Forming Machine is revolutionizing the roofing industry.Roofing materials play a crucial role in providing protection against external elements. Traditionally, materials like clay, concrete, and slate tiles have been used to create sturdy and visually appealing roofs. However, these materials have certain limitations, such as their weight, cost, and durability. Moreover, their installation process can be time-consuming and labor-intensive.The Color Steel Metal Glazed Tile Roll Forming Machine, developed by a leading machinery manufacturer, is designed to address these limitations and provide an efficient alternative for constructing high-quality roofs. This state-of-the-art machine enables the continuous production of metal glazed tiles with unparalleled precision, strength, and longevity.One of the key advantages of the Color Steel Metal Glazed Tile Roll Forming Machine is its ability to produce lightweight yet durable roofing materials. By using high-quality metal alloys, this machine creates tiles that are resistant to corrosion, weathering, and fire. Additionally, the lightweight nature of these tiles eases the burden on the building structure, reducing costs and strengthening overall stability.Furthermore, the Color Steel Metal Glazed Tile Roll Forming Machine has revolutionized the roof installation process. Traditional roofing materials often require time-consuming manual labor, resulting in increased project durations and expenses. However, this innovative machine automates the entire production process, significantly reducing labor costs and installation time. With integrated cutting, bending, and shaping mechanisms, the machine ensures each tile is uniformly manufactured to exact specifications, thereby streamlining the roofing process and delivering consistent quality.Additionally, the Color Steel Metal Glazed Tile Roll Forming Machine offers unrivaled design flexibility. Unlike traditional roofing materials, which are limited in terms of color, pattern, and shape, the machine can create a wide range of customizable tile designs. The machine supports various color coatings and embossing patterns, allowing architects and homeowners to personalize their roofs while enhancing the overall aesthetic appeal of the structure.With sustainability becoming increasingly important in the construction industry, the Color Steel Metal Glazed Tile Roll Forming Machine truly shines. The metal tiles produced by this machine are highly recyclable, reducing waste and contributing to a greener environment. Additionally, the sustainable production process of the machine minimizes its carbon footprint, making it an environmentally responsible choice for roofing needs.In conclusion, the Color Steel Metal Glazed Tile Roll Forming Machine is making waves in the roofing industry. Its lightweight yet durable metal tiles, efficient production process, design flexibility, and sustainability make it a game-changer in the construction sector. As technology continues to advance, it is clear that innovative solutions like this machine will reshape the way we build, proving that there is always room for improvement in even the most traditional industries.