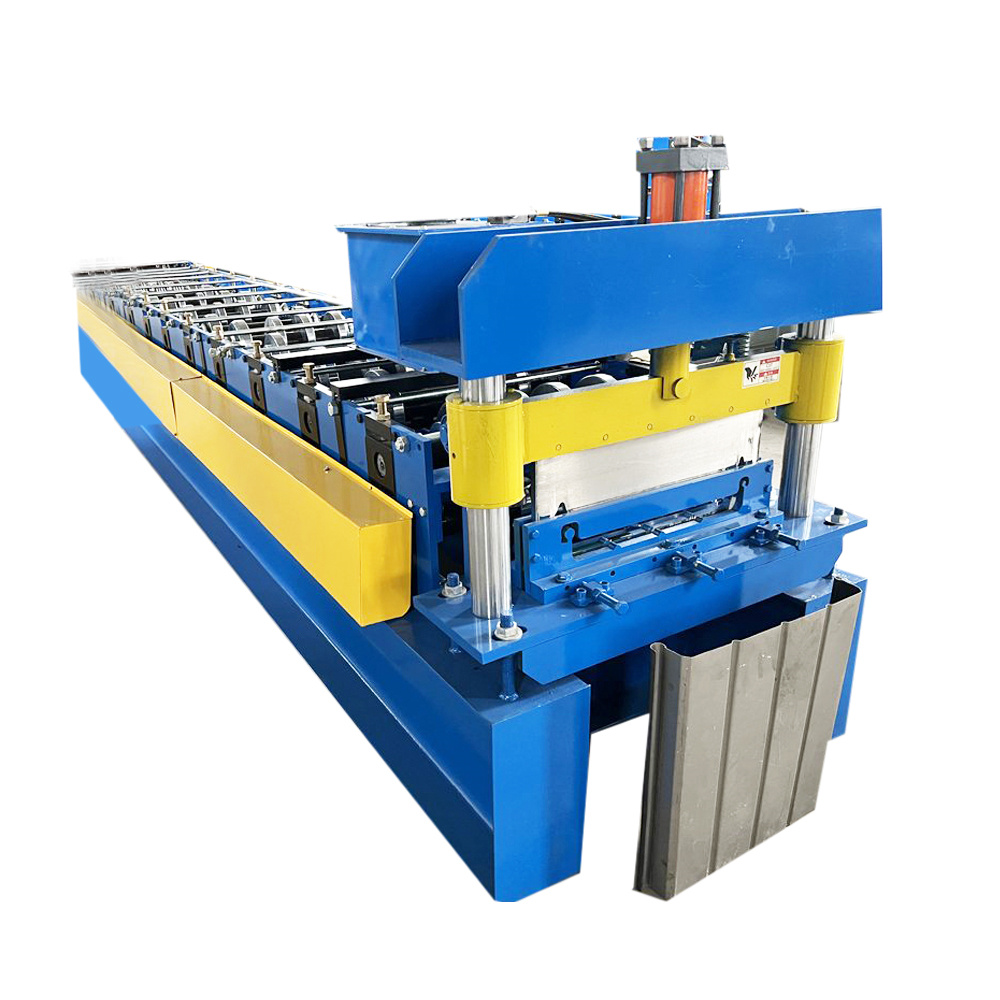

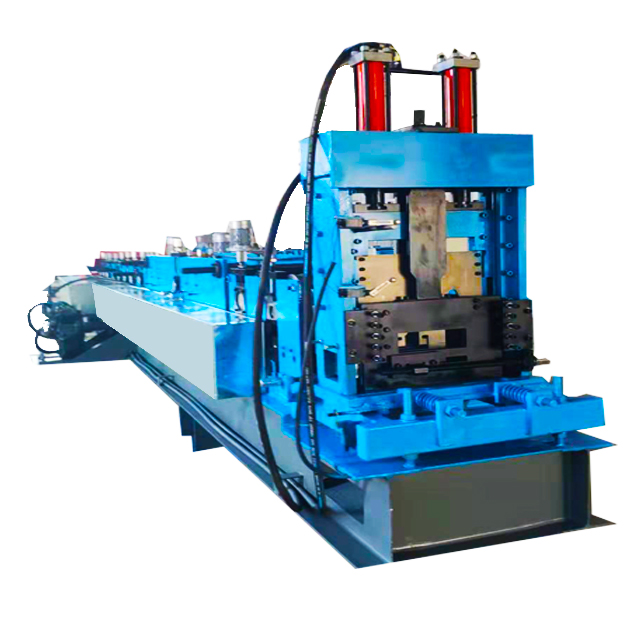

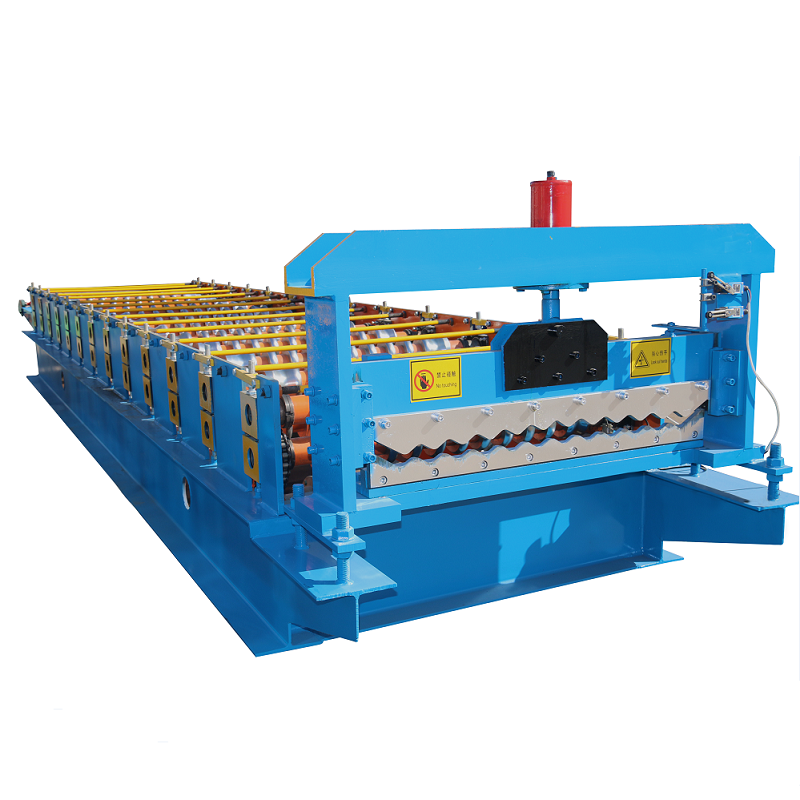

Standing Seam Roof Making Machine Standing Seam Roof Making Machine Forming Machine,it is our company most popular products in building materials machine. For roof sheet, it include many type according to its different shape, popular type include corrugated tile roll forming machine, trapezoidal tile roll forming machine,glazed tile roll forming machine, ridge cap roll forming machine and other type profile panel roll forming machine. When you choose Standing Seam Roof Making Machine, you had better learn popular shape in local,also raw material is an important considering data, if do not have good supplier in local, we can assist you purchase it in China together. we are professional factory and in this area for many years, any requires please contact us at any time!

Standing Seam Roof Making Machine Standing Seam Roof Making Machine Forming Machine,it is our company most popular products in building materials machine. For roof sheet, it include many type according to its different shape, popular type include corrugated tile roll forming machine, trapezoidal tile roll forming machine,glazed tile roll forming machine, ridge cap roll forming machine and other type profile panel roll forming machine. When you choose Standing Seam Roof Making Machine, you had better learn popular shape in local,also raw material is an important considering data, if do not have good supplier in local, we can assist you purchase it in China together. we are professional factory and in this area for many years, any requires please contact us at any time!

Wooden case and full container

1. Who are we? We are based in Henan, China, start from 2022,sell to Southeast Asia(20.00%),North America(15.00%),South America(15.00%),Africa(15.00%),Domestic Market(10.00%),Eastern Europe(5.00%),Mid East(5.00%),South Asia(5.00%),Central America(3.00%),Western Europe(2.00%),Oceania(2.00%),Eastern Asia(1.00%),Northern Europe(1.00%),Southern Europe(1.00%). There are total about 11-50 people in our office. 2. How can we guarantee quality? Always a pre-production sample before mass production; Always final Inspection before shipment; 3.What can you buy from us? roll forming machine,roof sheet machine,c u z purlin machine,cold bending machine,roll former 4. Why should you buy from us not from other suppliers? Henan Hoson CNC Machinery Co.,Ltd. focus on one-stop service solutionsfor metal cold forming machine. Our factory is specialized in manufacturing color steel forming machine,C&Zpurlin machine ,glazed tile forming machine. 5. What services can we provide? Accepted Delivery Terms: FOB,CFR,CIF,EXW,Express Delivery; Accepted Payment Currency:USD,EUR,CNY; Accepted Payment Type: T/T,MoneyGram; Language Spoken:English,Chinese| item | value |

| Applicable Industries | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Energy & Mining |

| Tile Type | Steel |

| Use | ROOF |

| Production Capacity | 12-18m/min |

| Voltage | 380V 50Hz 3phases |

| Dimension(L*W*H) | 6.5*1.8*1.6 meter |

| Weight | 3500kg |

| Warranty | 1 Year |

| Rolling thinckness | 0.3-0.8mm |

| Feeding width | 400mm |

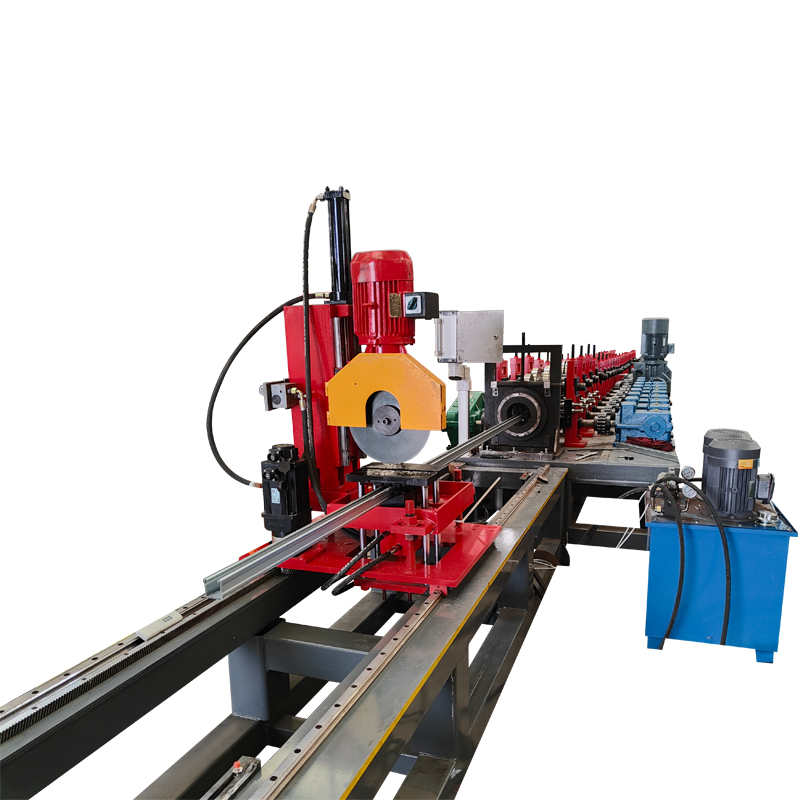

Forming roller 1. Number of molding machine lanes: 10-18 rows 2. Roller material: 45# steel forged parts, hard chrome plating on the surface after finishing Cutting Blade 1. Cutting method: hydraulic shearing 2. Forming scissors blade material: Cr12 3. Shear blade heat treatment: HRC58°-60°Molybdenum vanadium

Forming roller 1. Number of molding machine lanes: 10-18 rows 2. Roller material: 45# steel forged parts, hard chrome plating on the surface after finishing Cutting Blade 1. Cutting method: hydraulic shearing 2. Forming scissors blade material: Cr12 3. Shear blade heat treatment: HRC58°-60°Molybdenum vanadium