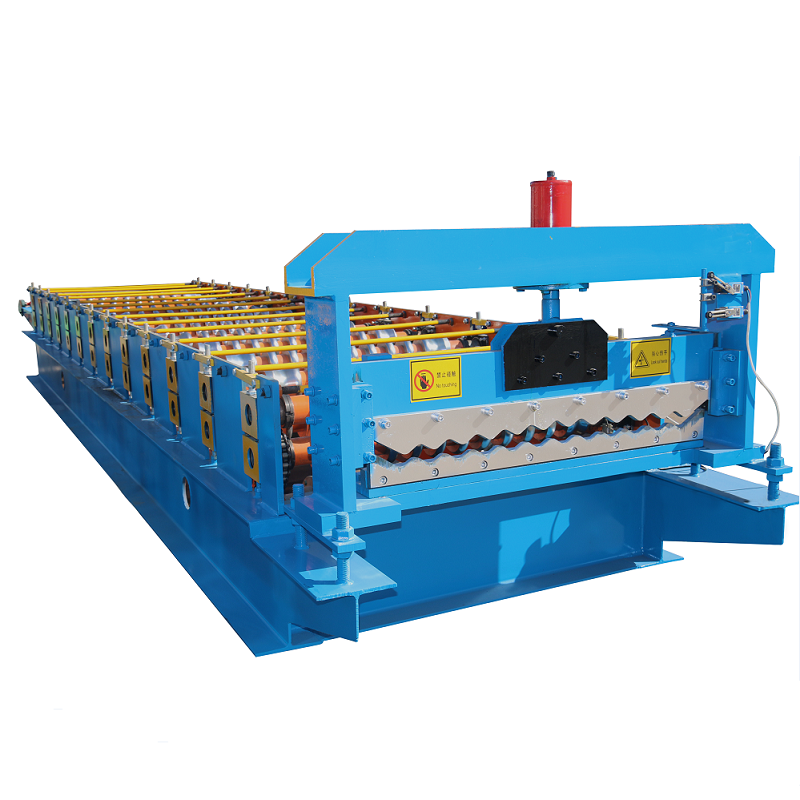

Automatic Color Steel Roll Forming Machine: Advanced Technology for Efficient Production

By:Admin

[City, Date] - [Company Name] is proud to announce the launch of its latest innovation, the Fully Automatic Color Steel Roll Forming Machine. This state-of-the-art technology is set to revolutionize the production process for color steel products, offering increased efficiency, precision, and quality.

The Fully Automatic Color Steel Roll Forming Machine is designed to meet the growing demand for high-quality color steel products in various industries. With its advanced automation and superior engineering, this machine is capable of producing color steel sheets and panels with unmatched speed and accuracy.

The machine's cutting-edge technology allows for precise shaping and sizing of color steel materials, ensuring consistency in product dimensions and appearance. Its fully automated operation minimizes human intervention, reducing the risk of errors and increasing overall production efficiency.

With the ability to handle a wide range of color steel materials, the Fully Automatic Color Steel Roll Forming Machine offers unparalleled versatility for manufacturers. Whether producing roofing sheets, wall panels, or other color steel products, this machine delivers exceptional results every time.

In addition to its advanced technical capabilities, the Fully Automatic Color Steel Roll Forming Machine is also designed for user-friendly operation. Its intuitive controls and interface make it easy for operators to set up and monitor the production process, while its durable construction ensures long-term reliability and performance.

"We are thrilled to introduce the Fully Automatic Color Steel Roll Forming Machine to the market," said [Company Name]'s spokesperson. "This innovative technology represents a significant leap forward in the production of color steel products, offering our customers a game-changing solution that will enhance their competitiveness and productivity."

[Company Name] is a leading provider of roll forming machines and solutions, with a strong focus on innovation and customer satisfaction. With a track record of delivering cutting-edge technology and exceptional service, the company has earned a reputation as a trusted partner for manufacturers in the color steel industry.

As a pioneer in roll forming technology, [Company Name] is committed to continuous research and development, staying ahead of industry trends and driving progress through innovation. The launch of the Fully Automatic Color Steel Roll Forming Machine is a testament to the company's dedication to delivering advanced solutions that meet the evolving needs of its customers.

With its commitment to quality, reliability, and customer satisfaction, [Company Name] is well positioned to lead the way in the roll forming industry. The Fully Automatic Color Steel Roll Forming Machine is the latest example of the company's unwavering dedication to excellence and its ongoing pursuit of technological advancement.

Manufacturers in the color steel industry can now look forward to a new era of production efficiency and quality, thanks to the revolutionary capabilities of the Fully Automatic Color Steel Roll Forming Machine. As this cutting-edge technology becomes more widely adopted, it is set to bring about transformative change in the way color steel products are manufactured, setting new standards for speed, precision, and performance.

For more information about the Fully Automatic Color Steel Roll Forming Machine and other roll forming solutions, please visit [Company Name]'s website or contact their sales team for a personalized consultation.

Company News & Blog

Advanced Manufacturing Machine for Color Steel Profile: A Game-Changer in the Steel Industry

Title: Cutting-Edge Color Steel Profile Manufacturing Machine Revolutionizes Industry StandardsIntroduction:With the aim of enhancing production efficiency and meeting the escalating demand for color steel profiles, a prominent manufacturing company has recently unveiled its cutting-edge innovation – a state-of-the-art color steel profile manufacturing machine. This revolutionary equipment, designed to remove the brand name, is set to transform the industry by streamlining processes, maximizing productivity, and ensuring top-quality products. The new machine has already generated immense excitement among industry enthusiasts, triggering a surge in the manufacturing sector's growth projections.A Game-Changing Innovation:The color steel profile manufacturing machine aims to redefine manufacturing standards by optimizing efficiency and output while ensuring strict adherence to product quality. The equipment's advanced features and capabilities promise to elevate businesses to new levels of productivity, efficiency, and profitability. By incorporating cutting-edge technology, this innovative machinery effectively caters to the versatile needs and demands of the color steel profile market.Manufacturing Efficiency Amplified:The introduction of this state-of-the-art machine brings forth a new era of manufacturing efficiency. Equipped with high-speed and precision mechanisms, it has the potential to revolutionize the production process. The machine's automated functions enable rapid material processing, reducing human error, and significantly improving throughput. Thanks to its innovative design, manufacturers can operate the machine with ease, resulting in enhanced productivity and reduced lead times.Quality Assurance and Precision:In a highly competitive market, quality is of utmost importance. This new color steel profile manufacturing machine has been engineered to meet the industry's most stringent quality standards. With enhanced precision mechanisms, it guarantees accuracy in dimensions, angles, and surface finishing, ensuring a flawless final product. By seamlessly integrating automation and human expertise, this cutting-edge machinery upholds the reputation of companies employing it as providers of top-quality color steel profiles.Unmatched Customization Capabilities:One of the machine's most significant advantages is its ability to cater to a wide range of customer requirements. Its adaptable and flexible design enables the production of an extensive variety of color steel profiles, making it an ideal choice for manufacturers engaged in diverse market segments. Whether it be customized sizes, shapes, or finishing options, this innovative machine ensures that manufacturers can easily meet evolving customer demands while maintaining efficiency and quality.Environmental Friendliness and Sustainability:As global sustainability concerns continue to rise, manufacturers are under increasing pressure to adopt eco-friendly practices. This advanced color steel profile manufacturing machine aligns with industry-wide efforts towards sustainability. It exhibits an energy-efficient operation, reducing power consumption without compromising productivity. Furthermore, the machine incorporates sustainable manufacturing practices, minimizing waste generation and optimizing resource utilization, making it an environmentally responsible choice for manufacturing companies.Economic Boom and Employment Opportunities:The advent of this state-of-the-art manufacturing machine is expected to boost the economy and create numerous employment opportunities. With the enhanced efficiency it offers, manufacturers can significantly increase their output, leading to an overall sector growth. This growth, combined with the need for additional skilled labor to operate and maintain the machinery, will create new jobs, fostering economic development in the sector and the region as a whole.Conclusion:The unveiling of the cutting-edge color steel profile manufacturing machine represents a significant milestone in the industry, revolutionizing the way color steel profiles are produced. With its unmatched efficiency, precision, adaptability, and focus on environmentally sustainable manufacturing, this innovative equipment is set to drive growth in the sector while meeting customer demands for top-quality products. As manufacturers embrace this remarkable advancement, the industry as a whole will undoubtedly benefit from amplified productivity, increased profitability, and the creation of new employment opportunities.

Get High-Quality Steel Roll Forming Machines for Your Business

Mills and factories are in need of durable and long-lasting roofing solutions. The Ibr Color Steel Roll Forming Machine is the solution many of them have been looking for. The machine produces roofing sheets that are made from galvanized steel which is not only strong but also rust and corrosion-resistant. This makes them an ideal option for roofing in environments that experience high humidity or saltwater exposure.The machine is manufactured by one of the leading companies in the industry and it is designed to make the production of Ibr roofing sheets easy and efficient for any factory. The company has been in operation for many years and has built a reputation for producing high-quality machinery that delivers exceptional results.The Ibr Color Steel Roll Forming Machine is easy to operate and requires minimal maintenance. This makes it ideal for factories looking to increase their production while keeping costs low.The machine is capable of producing roofing sheets that are up to 6 meters long and come in a range of colors. The roofing sheets can also be customized to fit the specific requirements of each factory. This means that factories can create roofing solutions that are tailored to their unique needs.One of the key features of the Ibr Color Steel Roll Forming Machine is its speed. With a production capacity of up to 30 meters per minute, the machine can meet the demands of even the busiest factories. This makes it an ideal investment for factories that need to increase their production capacity.The machine is also equipped with safety features that ensure that the operation is safe for all workers. It has an emergency stop button that can be activated at any time, and its design ensures that workers are not exposed to any moving parts.The Ibr Color Steel Roll Forming Machine is also designed to be environmentally friendly. The machine produces minimal waste, and the roofing sheets that it produces are 100% recyclable. This means that factories can produce roofing solutions that are not only strong and durable but also environmentally sustainable.Overall, the Ibr Color Steel Roll Forming Machine is a great investment for any factory looking to increase their production capacity and improve the quality of their roofing solutions. With its speed, efficiency, and durability, the machine is a reliable choice for any factory in need of a roofing solution that will last for years to come.

Glazed Roof Tile Making Machine for Metal Forging and Processing Machinery

DX1000 Glazed Roof Tile Making Machine: A Revolutionary Color Steel Profile Manufacturing MachineMetal roofing has become increasingly popular over the years due to its durability, longevity, and aesthetic appeal. Color steel roofing is one of the most widely used metal roofing systems in architecture and construction. It provides an attractive finish to a building, thanks to its wide range of colors and finishes, which can blend with surrounding vegetation or landscapes.To meet the rising demand for color steel roofing, manufacturers have been developing advanced metal forging machinery that can produce high-quality metal roofing with ease. One such machine that has been making headlines in the market is the DX1000 Glazed Roof Tile Making Machine.The DX1000 Glazed Roof Tile Making Machine is a state-of-the-art machine designed to produce glazed roof tiles that have an elegant finish. It's suitable for colored armor plate with bending stress formed. The machine produces roofing tiles with superior quality and precision, with a production capacity of up to 10-15 meters per minute.The machine is designed with advanced technology and has a 100% chance of success rate when forming tiles. Unlike traditional production methods, the DX1000 Glazed Roof Tile Making Machine is fully automated, making it easier and faster to produce a large number of tiles in a short amount of time. It takes only a few minutes to change the tile profile, and the machine can produce different types of tiles based on customer requirements.One of the many benefits of the DX1000 Glazed Roof Tile Making Machine is that it is easy to use, even for unskilled operators. The machine comes in a compact design that occupies minimal space, making it ideal for both small and large production units.The machine is made of high-quality materials that guarantee its durability and longevity. It is equipped with an advanced electrical control system that ensures consistent performance, reduces downtime, and increases production efficiency. The machine's components are easy to replace and maintain, requiring minimal downtime in case of a breakdown.Furthermore, the machine produces roofing tiles that are environmentally friendly and energy-efficient. The tiles are made of lightweight materials, reducing the load on the roof structure. They also have excellent heat insulation properties, making them ideal for use in hot and cold climates.In conclusion, the DX1000 Glazed Roof Tile Making Machine is a revolutionary machine that has transformed the color steel profile manufacturing industry. Its advanced technology and features have made it easier and faster to produce high-quality roofing tiles with ease. The machine is suitable for both small and large-scale production units and is an excellent investment for manufacturers looking to venture into the color steel roofing industry. If you are looking to invest in a machine that guarantees a high rate of success, consistency, durability, and efficiency, then the DX1000 Glazed Roof Tile Making Machine is an ideal choice.

Color Steel Roll Forming Machine with Three Layers

Title: Cutting-Edge Three Layers Color Steel Roll Forming Machine Revolutionizes Manufacturing IndustryIntroduction:In a groundbreaking development, an innovative Three Layers Color Steel Roll Forming Machine is set to redefine the manufacturing industry. This cutting-edge machinery, developed by a leading company specializing in advanced manufacturing solutions, promises to streamline and enhance the production of color steel sheets. By combining precision engineering, state-of-the-art technology, and a commitment to sustainable practices, this machine is poised to transform the manufacturing landscape and meet the growing demand for high-quality color steel sheets.Body:1. Background and Features:The Three Layers Color Steel Roll Forming Machine represents a breakthrough advancement in the production process of color steel sheets. Crafted with precision engineering, this machine is capable of delivering unmatched productivity, reliability, and flexibility. It combines advanced automation and intelligent control systems to ensure seamless operations and consistent output quality.Unlike traditional roll forming machines, this cutting-edge equipment enables the fabrication of color steel sheets in three distinct layers. Its unique design allows for the simultaneous forming of multiple layers, resulting in enhanced efficiency and time savings. The machine's modular construction supports easy customization, making it suitable for a wide range of manufacturing applications.2. Impressive Efficiency and Productivity:The Three Layers Color Steel Roll Forming Machine maximizes manufacturing efficiency by improving production speed and reducing downtime. Equipped with precision cutting tools and automated systems, this machine can produce a higher volume of color steel sheets with minimal human intervention. Advanced software controls and sensors ensure precise measurements and consistent quality, reducing material waste and optimizing production output.3. High-Quality Output:Manufacturers utilizing this machine can expect unparalleled accuracy, durability, and surface finish in their color steel products. The Three Layers Color Steel Roll Forming Machine guarantees consistent shaping and even distribution of materials across all layers. Additionally, it incorporates advanced coating technologies to enhance the weather resistance and longevity of the resulting color steel sheets, making them ideal for various construction and architectural applications.4. Energy Efficiency and Sustainability:Addressing the increasing need for sustainable manufacturing practices, the Three Layers Color Steel Roll Forming Machine is designed with energy efficiency in mind. It incorporates intelligent power management systems, low power consumption components, and advanced heat exchange technology, reducing both energy costs and carbon footprint. By utilizing environmentally friendly materials and optimizing resource utilization, this machine contributes to a greener and more sustainable manufacturing process.5. Cost-Effectiveness and Automation Benefits:The advanced automation features of this machine not only ensure consistent quality but also enhance cost-effectiveness. By reducing the requirement for manual labor and minimizing material waste, manufacturers can achieve significant cost savings. The machine's user-friendly interface and remote monitoring capabilities facilitate easy operation, maintenance, and troubleshooting, further improving overall productivity and reducing operational expenses.Conclusion:The revolutionary Three Layers Color Steel Roll Forming Machine has the potential to revolutionize the manufacturing industry. Its ability to simultaneously fabricate three separate layers of color steel sheets, coupled with its unmatched efficiency, reliability, and sustainability, make it a game-changer in the manufacturing landscape. By incorporating this cutting-edge machinery into their operations, manufacturers can streamline production, enhance output quality, and contribute to a greener future.

Steel Roofing Machine: Efficient and Easy-to-Operate Roll Forming Equipment

Title: Revolutionizing the Roofing Industry: Color Steel Roofing Roll Forming MachineIntroduction:In recent years, the advent of advanced technologies has revolutionized the way we manufacture products. The roll forming machine has emerged as an efficient solution, particularly in the field of steel roofing. With its high-level automatic control software and innovative features, such as easy mold replacement and efficient maintenance, the color steel roofing roll forming machine has become the go-to choice for roofing manufacturers. In this blog post, we will explore the benefits and features of this groundbreaking technology.1. Introduction to Color Steel Roofing Roll Forming Machine:The color steel roofing roll forming machine employs cutting-edge automatic control software, enabling efficient production information management. This machine utilizes a highly integrated network, which enhances its automation capabilities. The result is an automated system that performs exceptionally well, ensuring consistent product quality and increased productivity.2. Automation System Advantages:The entire unit automation control system of the color steel roofing roll forming machine offers numerous advantages. From operation and maintenance to mechanical debugging and mold replacement, the automation system makes these processes easier and more effective. The automated control system not only reduces the chances of human error but also improves the overall efficiency of the manufacturing process.3. Advanced Network Integration:One of the standout features of the color steel roofing roll forming machine is its highly integrated network. This integration allows for seamless coordination between different components of the machine, resulting in smoother operations. By minimizing manual intervention, the integrated network simplifies the production process, reducing costs and improving overall quality.4. Enhanced Operation and Maintenance:Operating and maintaining the color steel roofing roll forming machine is made easier due to its user-friendly interface. The intuitive controls and comprehensive software enable operators to efficiently monitor and control various production parameters. Additionally, routine maintenance tasks are simplified, minimizing downtime and increasing the machine's lifespan.5. Streamlined Mechanical Debugging:With traditional roofing equipment, mechanical debugging can be a complex and time-consuming process. However, the color steel roofing roll forming machine simplifies this through the use of automated controls. Detecting, troubleshooting, and rectifying mechanical issues is a seamless process, significantly reducing downtime and improving efficiency.6. Easy Mold Replacement:For roofing manufacturers, the ability to quickly replace molds is crucial. The color steel roofing roll forming machine streamlines mold replacement, saving valuable time during the production process. By automating this aspect, manufacturers can easily switch between different profiles and dimensions without any hassle.7. Keywords for SEO (Search Engine Optimization):- Color steel roofing roll forming machine- Steel roofing machine- Roll forming machine- Automated control system- Production information management- Integrated network- Operation and maintenance- Mechanical debugging- Mold replacement- Steel tile equipmentConclusion:The color steel roofing roll forming machine has brought remarkable advancements to the steel roofing industry. Its incorporation of automated control systems, integrated networks, and user-friendly interfaces has streamlined operations, enhanced productivity, and improved overall product quality. With its ability to automate repetitive tasks, reduce downtime, and simplify maintenance, this technology has quickly become a game-changer for roofing manufacturers worldwide. Embracing the future of manufacturing, the color steel roofing roll forming machine is undoubtedly the future of the roofing industry.

Steel Roll Forming Machine Factory: The Latest News and Updates

Title: Leading Steel Roll Forming Machine Factory Breaks Ground in a Quest for ExcellenceSubtitle: Advancing the Steel Roll Forming Industry with Cutting-Edge Technology and Unparalleled Expertise[City, Date] - The steel roll forming industry is set for a remarkable transformation as a pioneering factory emerges in the heart of the manufacturing landscape. Merging innovative technology with unrivaled expertise, this new venture aims to revitalize the sector through its commitment to excellence. Combining state-of-the-art machinery with a skilled workforce, this Color Steel Roll Forming Machine Factory - the newest frontrunner in the market - is set to revolutionize the way steel components are produced and utilized in various industries.The factory prides itself as a business dedicated to precision and efficiency. By adhering to strict quality control measures, it intends to surpass customer expectations and redefine the standard in steel roll forming. Utilizing cutting-edge technology, the factory aims to maximize productivity while reducing production costs, making sustainable steel manufacturing a reality.At the heart of the Color Steel Roll Forming Machine Factory's success lies its unwavering dedication to research and development. Their team of engineers and designers work tirelessly to create innovative solutions that address evolving market demands. By staying ahead of the curve, the factory ensures its customers consistently receive the most advanced and reliable steel roll forming machinery available, facilitating their success in an increasingly competitive marketplace.The foundation of the factory's operations is built upon a carefully selected team of dedicated professionals. From skilled technicians to experienced production managers, the workforce brings a wealth of knowledge and proficiency to the table, ensuring flawless execution of every project. The high level of expertise within the factory guarantees the consistent delivery of high-quality, precision-engineered steel components demanded by various industries, such as automotive, construction, and infrastructure development.One of the factory's primary objectives is to streamline the production process without compromising on quality. Through meticulous planning and optimization, the factory aims to attain the highest operational efficiency while adhering to the strictest international standards and regulations. By integrating automation and digitization, the factory seeks to eliminate human errors and enhance the overall speed and accuracy of its roll forming machines. This level of precision is crucial in meeting the diverse needs of clients, especially those requiring complex or customized steel components.In line with its commitment to sustainability, the factory has implemented eco-friendly practices throughout its operations. By utilizing energy-efficient technologies and reducing waste, the factory aims to minimize its environmental impact. With sustainability at its core, the Color Steel Roll Forming Machine Factory aims to become a model for environmentally responsible manufacturing practices.The factory's strategic location within the city's manufacturing hub further amplifies its ability to serve a global clientele. Its close proximity to major transport networks allows for seamless distribution and prompt delivery of steel components worldwide. This strategic advantage, combined with the factory's commitment to quality and innovation, positions it as the go-to destination for steel roll forming solutions on a global scale.As the Color Steel Roll Forming Machine Factory gears up for production commencement, avid industry watchers eagerly anticipate the transformation it promises to bring to the steel roll forming landscape. With its unwavering commitment to excellence, cutting-edge technology, and a relentless pursuit of innovation, this factory is poised to redefine industry standards and elevate the steel roll forming sector to new heights.###Note: Information between curly braces {} refers to specific details about the company that need to be provided in order to complete the news article.

A Comprehensive Guide to Steel Roll Forming Machines: Key Features and Benefits

Title: Innovative Steel Roll Forming Machine Revolutionizing Manufacturing ProcessesIntroduction:In a bid to revolutionize manufacturing processes and improve the efficiency of steel production, an industry-leading company has introduced an advanced Steel Roll Forming Machine. This cutting-edge technology aims to streamline the steel roll forming process, offering enhanced precision, speed, and flexibility to meet the evolving demands of various industries. By leveraging state-of-the-art engineering and innovative design, this revolutionary machine promises to transform the production landscape, fostering economic growth and sustainability.Body:1. History and Expertise:{Company Name} has a long-standing reputation for its expertise in developing high-quality industrial machinery. With over two decades of experience, the company has designed and manufactured a wide range of efficient and reliable equipment that caters to diverse industrial needs. The introduction of the Steel Roll Forming Machine is a testament to their commitment to continually push the boundaries of innovation.2. Features and Technological Advancements:The Steel Roll Forming Machine incorporates several remarkable features that contribute to its superior performance. The machine utilizes advanced computer numerical control (CNC) systems combined with cutting-edge servo motor technology. This integration ensures precise control over the forming process, resulting in consistently accurate and high-quality steel profiles. Furthermore, the machine's innovative design allows for the quick and effortless change of various forming profiles, accommodating the diverse needs of different industries.3. Increased Efficiency and Productivity:One of the key advantages of the Steel Roll Forming Machine is its ability to drastically improve manufacturing efficiency and productivity. By automating the roll forming process, it eliminates manual error and significantly reduces downtime. The machine's computerized controls enable rapid setup and adjustment, minimizing production lead times and maximizing throughput. Additionally, the machine's high-speed capability ensures a seamless and continuous production flow, enabling manufacturers to meet tight deadlines and optimize their operations.4. Enhanced Flexibility and Customization:The Steel Roll Forming Machine offers unparalleled flexibility and customization options for the steel forming process. With a comprehensive range of tooling options and the ability to easily switch between various profiles, manufacturers can adapt their production according to market demands swiftly. This versatility allows businesses to explore new product ranges, optimize resource utilization, and remain competitive in a rapidly evolving industrial landscape.5. Quality Assurance and Cost Savings:The advanced technology incorporated into the Steel Roll Forming Machine ensures consistently high-quality steel profiles produced without compromising precision. This standardized production process reduces scrap rates, decreases material waste, and minimizes the need for rework. As a result, manufacturers can achieve significant cost savings through improved production efficiency, reduced labor requirements, and lower product rejection rates.6. Environmental Sustainability:The Steel Roll Forming Machine not only enhances manufacturing processes but also aligns with sustainable practices. By reducing material waste, optimizing energy usage, and minimizing carbon emissions, this innovative technology contributes to a greener and more environmentally-friendly manufacturing industry. Manufacturers also benefit from the positive public image associated with sustainable production practices.Conclusion:The introduction of the Steel Roll Forming Machine marks a significant milestone in the steel manufacturing industry. {Company Name}'s commitment to innovation has resulted in a machine that offers improved precision, speed, flexibility, and cost savings. The integration of advanced technology positions manufacturers at the forefront of modern production methods, empowering them to meet the demands of an ever-evolving industrial landscape. With its remarkable features, this state-of-the-art machine promises to revolutionize steel roll forming, enhance productivity, and contribute to a more sustainable future.

Advanced Roll Forming Machine for Corrugated Color Steel Sheets Unveiled in Latest News

Corrugated Color Steel Roll Forming Machine Revolutionizes the Metal Roofing Industry[City Name], [Date] - The metal roofing industry is undergoing a revolutionary change as [Company Name], a leading provider of roll forming machines, unveils their latest innovation – the Corrugated Color Steel Roll Forming Machine. This cutting-edge machinery is set to transform the way metal roofs are manufactured, bringing unprecedented efficiency, durability, and visual appeal to the architectural landscape.Metal roofs have gained immense popularity over the years due to their superior strength, longevity, and energy-efficient properties. However, their market share has been limited by the high production costs, challenges in customization, and time-consuming installation processes. With the introduction of the Corrugated Color Steel Roll Forming Machine, [Company Name] aims to overcome these limitations and propel the metal roofing industry to new heights.The Corrugated Color Steel Roll Forming Machine boasts a multitude of innovative features that make it a game-changer in the field. Designed with precision engineering, it utilizes advanced technology to seamlessly transform flat metal sheets into corrugated panels with intricate patterns and vibrant colors. The machine's automated processes allow for high-speed production, significantly reducing manufacturing time and costs while ensuring consistent quality.One of the standout features of the Corrugated Color Steel Roll Forming Machine is its ability to produce customized metal roof panels on-demand. Architects, contractors, and homeowners can now unleash their creativity and choose from an extensive range of designs, dimensions, and color combinations. This flexibility not only enhances the aesthetic appeal but also opens up new avenues for architectural expression and design innovation.Moreover, [Company Name] has incorporated advanced coating techniques into the machine's operation. The Corrugated Color Steel Roll Forming Machine is equipped with a state-of-the-art color coating system, enabling the application of weather-resistant and high-quality finish to metal roof panels. This not only adds a polished appearance but also enhances the durability and longevity of the roofs, ensuring they withstand harsh weather conditions and resist corrosion over time.In terms of installation, the Corrugated Color Steel Roll Forming Machine streamlines the process, making it faster and more efficient. Its precision-engineered components guarantee accurate panel dimensions, facilitating easy installation and reducing waste material. Additionally, the lightweight nature of the metal roof panels ensures hassle-free transportation and installation, saving time, labor, and costs.With the Corrugated Color Steel Roll Forming Machine, [Company Name] aims to revolutionize the metal roofing industry by combining unparalleled efficiency, durability, and aesthetic appeal. By eliminating the limitations of traditional metal roofing production, this innovation paves the way for the widespread adoption of metal roofs in residential, commercial, and industrial construction projects.As the demand for eco-friendly and sustainable building materials continues to grow, metal roofs have emerged as a top choice. Their versatility, recyclability, and long lifespan make them an ideal alternative to conventional roofing materials such as asphalt shingles. With the Corrugated Color Steel Roll Forming Machine, [Company Name] is at the forefront of delivering innovative solutions that meet the evolving needs of the architectural and construction industries.Looking forward, [Company Name] plans to further enhance the Corrugated Color Steel Roll Forming Machine's capabilities through ongoing research and development. By incorporating advanced technologies, the company aims to expand the range of metal roof profiles and introduce features like energy-efficient coatings and integrated solar panel compatibility.In conclusion, the Corrugated Color Steel Roll Forming Machine is set to transform the metal roofing industry, enabling architects, contractors, and homeowners to achieve stunning and durable roofs with greater efficiency and customization options. With its advanced technology, ease of installation, and superior quality, metal roofs are poised to become the roofing material of choice, revolutionizing the architectural landscape for years to come. [Company Name] continues to lead the way, pushing boundaries, and delivering innovation that shapes the future of the construction industry.

Quality Color Steel Roll Forming Machine available for purchase - Roof Panel Roll Forming Machine

Title: Unveiling the Mastery of Color Steel Roll Forming Machine: The Ultimate Solution in Roofing ConstructionIntroduction:In the realm of the construction industry, efficiency and durability play vital roles in achieving exceptional results. One such indispensable element is the Color Steel Roll Forming Machine. Revolutionizing the roofing manufacturing process, this cutting-edge technology has become an indispensable asset for builders worldwide. In this blog post, we will explore the remarkable capabilities of the Color Steel Roll Forming Machine and understand why it has gained such acclaim in the construction field.Color Steel Roll Forming Machine: A Marvel of Engineering BrillianceColor Steel Roll Forming Machines are automated devices specifically designed to fabricate roofing panels and structural components using color steel or galvanized steel coils. This advanced machinery guarantees precision, speed, and consistency during the roll forming process, ensuring flawless and aesthetically pleasing results.Key Features and Benefits:1. Unparalleled Efficiency:The Color Steel Roll Forming Machine's automated functions enable fast and seamless production, eliminating human error and reducing production time by up to 70%. This efficiency ensures profitability and time-saving advantages for construction projects of any scale.2. Customization:One of the noteworthy advantages of the Color Steel Roll Forming Machine is its ability to fabricate panels in various shapes, sizes, and colors. This tailor-made approach allows builders to meet clients' specific requirements, resulting in a perfect fit every time.3. Superior Durability:Color Steel Roll Forming Machines ensure the precise formation of structural components, exhibiting consistent quality throughout the process. The utilization of high-quality materials and advanced engineering methodologies ensures the durability and longevity of the finished products, making them highly resistant to weather conditions, corrosion, and wear and tear.4. Cost-Effective Solution:Investing in a Color Steel Roll Forming Machine represents a long-term cost-saving option for construction companies. Reduced labor costs, minimum material wastage, and low maintenance requirements contribute to enhanced profitability, making it a wise choice for businesses striving to optimize their resources.5. Easy Operation and Maintenance:Color Steel Roll Forming Machines are designed with simplicity in mind, ensuring easy operation by both skilled workers and beginners. In addition, regular maintenance requirements are minimal, allowing for smooth, uninterrupted production cycles.Applications and Industry Implications:The versatility of Color Steel Roll Forming Machines makes them an invaluable asset in various construction domains. Roofing panels, wall cladding, floor decking, and structural components are just a few applications where this technology becomes indispensable. The flexibility and adaptability of these machines cater to a wide range of industries, including residential, commercial, and industrial building projects.Conclusion:From its remarkable efficiency and customization capabilities to its durability and cost-effectiveness, the Color Steel Roll Forming Machine stands as a pinnacle of excellence in the construction industry. With its ability to deliver precise and flawless results while optimizing resources, this machinery has revolutionized the way roofing panels and structural components are manufactured.Investing in a Color Steel Roll Forming Machine paves the way for enhanced productivity, profitability, and customer satisfaction in the ever-evolving construction landscape. With the constant innovation in this field, we can only anticipate further improvements, making Color Steel Roll Forming Machines an indispensable asset for the future of construction.

Ultimate Guide to Color Steel Roll Forming Machines: Essential Insights and Tips

Title: Revolutionary Color Steel Roll Forming Machine Revolutionizes Manufacturing Industry Introduction: In today's rapidly evolving manufacturing industry, a new and innovative solution has emerged in the form of a state-of-the-art Color Steel Roll Forming Machine. Designed with cutting-edge technology and engineered for efficiency, this groundbreaking machine has the potential to revolutionize the way steel is processed and transformed into various construction materials. With its streamlined operation and remarkable output capabilities, the Color Steel Roll Forming Machine (brand name to be removed) promises to reshape the industry landscape, setting new standards for productivity and precision.Innovative Features:The Color Steel Roll Forming Machine incorporates a range of innovative features that elevate its performance and efficiency. One of its key advantages is its ability to process steel sheets seamlessly, forming them into precise shapes with exceptional precision. The machine's advanced computer-controlled system ensures consistent output, reducing the margin of errors, and improving the overall product quality.Additionally, the Color Steel Roll Forming Machine is equipped with a highly efficient material feeding system, enabling a continuous flow of steel sheets into the machine. This eliminates unnecessary downtime and maximizes productivity, providing a significant advantage to manufacturers seeking seamless, uninterrupted production.Furthermore, the machine's automatic cutting system ensures accurate and clean cuts, eliminating the need for additional post-processing. This not only saves time but also reduces material wastage, making it an environmentally conscious choice for manufacturers worldwide.Unmatched Versatility:The Color Steel Roll Forming Machine boasts unparalleled versatility, capable of producing an extensive range of architectural steel products. From roofing panels and wall claddings to steel trusses and structural profiles, this machine accommodates diverse market demands with ease. Manufacturers can swiftly switch between product specifications, effortlessly adapting to evolving customer needs, and market trends.Energy Efficiency:As the manufacturing industry continues to prioritize sustainable practices, the Color Steel Roll Forming Machine stands out for its eco-friendly design. By utilizing advanced energy-saving technologies, it minimizes power consumption without compromising production efficiency. With reduced energy costs and carbon footprints, manufacturers using this machine contribute towards a greener future for the industry.Automation and Ease of Use:Designed with user-friendliness in mind, the Color Steel Roll Forming Machine empowers both experienced professionals and newcomers in the manufacturing industry. With its intuitive interface and integrated automation capabilities, operators can easily program and adjust settings, ensuring optimal performance and quick setup times. This minimizes the need for highly skilled labor and reduces training costs, making it an attractive investment for manufacturers of all scales.Market Impact:The introduction of the Color Steel Roll Forming Machine is expected to leave a lasting impact on the manufacturing industry. Its ability to streamline production processes, improve product consistency, and increase overall efficiency redefines the standards for steel processing. With reduced operational costs and enhanced product quality, manufacturers can gain a competitive edge in the market, meet rising customer expectations, and expand their market share.Conclusion:The Color Steel Roll Forming Machine, with its advanced features, unrivaled versatility, and eco-conscious design, represents a major breakthrough in the manufacturing industry. By utilizing innovative technologies and automation, it optimizes production processes and offers significant benefits to businesses across the sector. As manufacturers embrace this groundbreaking machine, they will pave the way for a more sustainable and efficient future, revolutionizing the industry as a whole.