Advanced Roll Forming Machine for Corrugated Color Steel Sheets Unveiled in Latest News

By:Admin

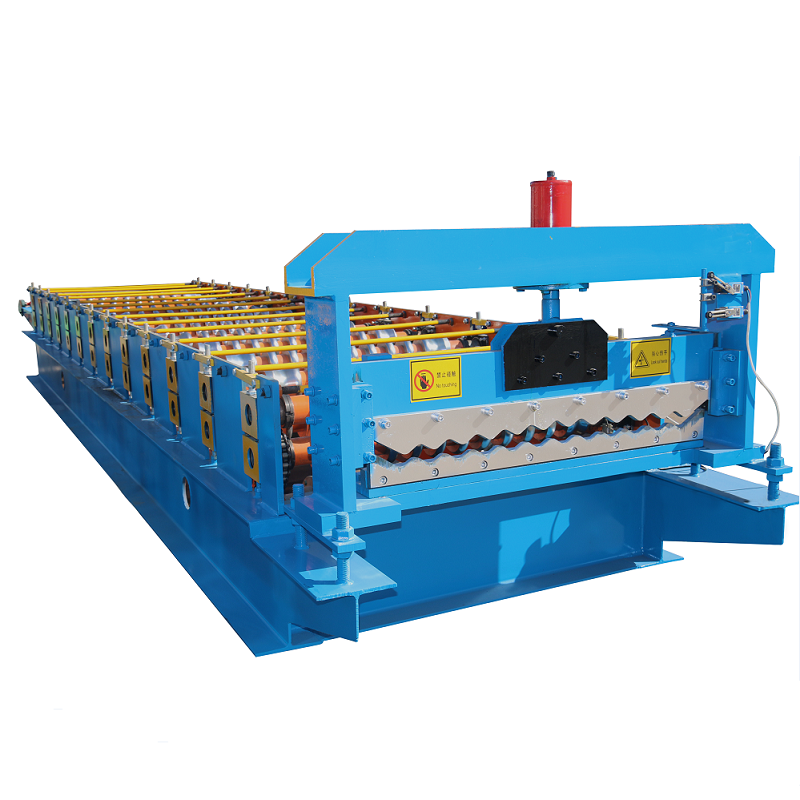

[City Name], [Date] - The metal roofing industry is undergoing a revolutionary change as [Company Name], a leading provider of roll forming machines, unveils their latest innovation – the Corrugated Color Steel Roll Forming Machine. This cutting-edge machinery is set to transform the way metal roofs are manufactured, bringing unprecedented efficiency, durability, and visual appeal to the architectural landscape.

Metal roofs have gained immense popularity over the years due to their superior strength, longevity, and energy-efficient properties. However, their market share has been limited by the high production costs, challenges in customization, and time-consuming installation processes. With the introduction of the Corrugated Color Steel Roll Forming Machine, [Company Name] aims to overcome these limitations and propel the metal roofing industry to new heights.

The Corrugated Color Steel Roll Forming Machine boasts a multitude of innovative features that make it a game-changer in the field. Designed with precision engineering, it utilizes advanced technology to seamlessly transform flat metal sheets into corrugated panels with intricate patterns and vibrant colors. The machine's automated processes allow for high-speed production, significantly reducing manufacturing time and costs while ensuring consistent quality.

One of the standout features of the Corrugated Color Steel Roll Forming Machine is its ability to produce customized metal roof panels on-demand. Architects, contractors, and homeowners can now unleash their creativity and choose from an extensive range of designs, dimensions, and color combinations. This flexibility not only enhances the aesthetic appeal but also opens up new avenues for architectural expression and design innovation.

Moreover, [Company Name] has incorporated advanced coating techniques into the machine's operation. The Corrugated Color Steel Roll Forming Machine is equipped with a state-of-the-art color coating system, enabling the application of weather-resistant and high-quality finish to metal roof panels. This not only adds a polished appearance but also enhances the durability and longevity of the roofs, ensuring they withstand harsh weather conditions and resist corrosion over time.

In terms of installation, the Corrugated Color Steel Roll Forming Machine streamlines the process, making it faster and more efficient. Its precision-engineered components guarantee accurate panel dimensions, facilitating easy installation and reducing waste material. Additionally, the lightweight nature of the metal roof panels ensures hassle-free transportation and installation, saving time, labor, and costs.

With the Corrugated Color Steel Roll Forming Machine, [Company Name] aims to revolutionize the metal roofing industry by combining unparalleled efficiency, durability, and aesthetic appeal. By eliminating the limitations of traditional metal roofing production, this innovation paves the way for the widespread adoption of metal roofs in residential, commercial, and industrial construction projects.

As the demand for eco-friendly and sustainable building materials continues to grow, metal roofs have emerged as a top choice. Their versatility, recyclability, and long lifespan make them an ideal alternative to conventional roofing materials such as asphalt shingles. With the Corrugated Color Steel Roll Forming Machine, [Company Name] is at the forefront of delivering innovative solutions that meet the evolving needs of the architectural and construction industries.

Looking forward, [Company Name] plans to further enhance the Corrugated Color Steel Roll Forming Machine's capabilities through ongoing research and development. By incorporating advanced technologies, the company aims to expand the range of metal roof profiles and introduce features like energy-efficient coatings and integrated solar panel compatibility.

In conclusion, the Corrugated Color Steel Roll Forming Machine is set to transform the metal roofing industry, enabling architects, contractors, and homeowners to achieve stunning and durable roofs with greater efficiency and customization options. With its advanced technology, ease of installation, and superior quality, metal roofs are poised to become the roofing material of choice, revolutionizing the architectural landscape for years to come. [Company Name] continues to lead the way, pushing boundaries, and delivering innovation that shapes the future of the construction industry.

Company News & Blog

High-Quality Profile Roll Forming Machine for Color Steel Production - A Must-Have for Efficient Manufacturing

Color Steel Profile Roll Forming Machine Revolutionizes the Industry with High Quality Products and Increased Efficiency(Color Steel Profile Roll Forming Machine) has introduced a game-changing Color Steel Profile Roll Forming Machine that is set to take the industry by storm. With its state-of-the-art technology, this machine is set to revolutionize the manufacturing process and offer a new level of efficiency and quality in the production of color steel profiles.This new Color Steel Profile Roll Forming Machine is a high-performance piece of equipment that is designed to deliver superior results. It is capable of producing high-quality color steel profiles with precision and accuracy, ensuring that every product is of the highest quality. With its high-speed production capabilities and advanced features, this machine is set to become the go-to choice for manufacturers of color steel profiles.One of the key features of this new Color Steel Profile Roll Forming Machine is its ability to produce profiles with greater accuracy and consistency than ever before. The machine is equipped with advanced sensors that monitor the production process in real-time, ensuring that each profile is produced to exact specifications. This reduces the risk of errors and ensures that the final product is of the highest quality.Another key benefit of the new Color Steel Profile Roll Forming Machine is its increased production speed. With its high-speed production capabilities, the machine can produce color steel profiles at a much faster rate than traditional manufacturing methods. This not only increases efficiency but also reduces the overall cost of production.The machine is also designed to be easy to use and operate. It is equipped with an intuitive user interface that makes it easy for operators to set up and monitor the production process. This reduces the need for extensive training and ensures that the production process runs smoothly and efficiently.In addition to its advanced features and capabilities, the new Color Steel Profile Roll Forming Machine is also built to last. It is constructed from high-quality materials that are designed to withstand the rigors of daily use. This ensures that the machine will continue to deliver superior results for many years to come.The introduction of this new Color Steel Profile Roll Forming Machine is a major step forward for the industry. It offers manufacturers a new level of efficiency and quality in the production of color steel profiles, and is sure to become the go-to choice for manufacturers around the world.About (Company Introduction)(Company Name) is a leading provider of innovative manufacturing solutions. With over (number) years of experience in the industry, the company has established a reputation for delivering high-quality products and services that meet the needs of its customers.The company's product portfolio includes a wide range of manufacturing equipment, including roll forming machines, slitting machines, tube mills, and more. These products are designed to deliver superior performance, accuracy, and efficiency, allowing manufacturers to increase productivity and reduce costs.At the heart of (Company Name)'s success is its commitment to customer satisfaction. The company works closely with its customers to understand their needs and develop customized solutions that meet their unique requirements. This customer-centric approach has helped the company establish long-term relationships with its customers and earn their trust and loyalty.With the introduction of the new Color Steel Profile Roll Forming Machine, (Company Name) continues to push the boundaries of innovation and set new standards of excellence in the industry. The company's commitment to quality, efficiency, and customer satisfaction is evident in every product it produces, and is a testament to its ongoing success.

Advanced Roll Forming Machine for Corrugated Color Steel Sheets Unveiled in Latest News

Corrugated Color Steel Roll Forming Machine Revolutionizes the Metal Roofing Industry[City Name], [Date] - The metal roofing industry is undergoing a revolutionary change as [Company Name], a leading provider of roll forming machines, unveils their latest innovation – the Corrugated Color Steel Roll Forming Machine. This cutting-edge machinery is set to transform the way metal roofs are manufactured, bringing unprecedented efficiency, durability, and visual appeal to the architectural landscape.Metal roofs have gained immense popularity over the years due to their superior strength, longevity, and energy-efficient properties. However, their market share has been limited by the high production costs, challenges in customization, and time-consuming installation processes. With the introduction of the Corrugated Color Steel Roll Forming Machine, [Company Name] aims to overcome these limitations and propel the metal roofing industry to new heights.The Corrugated Color Steel Roll Forming Machine boasts a multitude of innovative features that make it a game-changer in the field. Designed with precision engineering, it utilizes advanced technology to seamlessly transform flat metal sheets into corrugated panels with intricate patterns and vibrant colors. The machine's automated processes allow for high-speed production, significantly reducing manufacturing time and costs while ensuring consistent quality.One of the standout features of the Corrugated Color Steel Roll Forming Machine is its ability to produce customized metal roof panels on-demand. Architects, contractors, and homeowners can now unleash their creativity and choose from an extensive range of designs, dimensions, and color combinations. This flexibility not only enhances the aesthetic appeal but also opens up new avenues for architectural expression and design innovation.Moreover, [Company Name] has incorporated advanced coating techniques into the machine's operation. The Corrugated Color Steel Roll Forming Machine is equipped with a state-of-the-art color coating system, enabling the application of weather-resistant and high-quality finish to metal roof panels. This not only adds a polished appearance but also enhances the durability and longevity of the roofs, ensuring they withstand harsh weather conditions and resist corrosion over time.In terms of installation, the Corrugated Color Steel Roll Forming Machine streamlines the process, making it faster and more efficient. Its precision-engineered components guarantee accurate panel dimensions, facilitating easy installation and reducing waste material. Additionally, the lightweight nature of the metal roof panels ensures hassle-free transportation and installation, saving time, labor, and costs.With the Corrugated Color Steel Roll Forming Machine, [Company Name] aims to revolutionize the metal roofing industry by combining unparalleled efficiency, durability, and aesthetic appeal. By eliminating the limitations of traditional metal roofing production, this innovation paves the way for the widespread adoption of metal roofs in residential, commercial, and industrial construction projects.As the demand for eco-friendly and sustainable building materials continues to grow, metal roofs have emerged as a top choice. Their versatility, recyclability, and long lifespan make them an ideal alternative to conventional roofing materials such as asphalt shingles. With the Corrugated Color Steel Roll Forming Machine, [Company Name] is at the forefront of delivering innovative solutions that meet the evolving needs of the architectural and construction industries.Looking forward, [Company Name] plans to further enhance the Corrugated Color Steel Roll Forming Machine's capabilities through ongoing research and development. By incorporating advanced technologies, the company aims to expand the range of metal roof profiles and introduce features like energy-efficient coatings and integrated solar panel compatibility.In conclusion, the Corrugated Color Steel Roll Forming Machine is set to transform the metal roofing industry, enabling architects, contractors, and homeowners to achieve stunning and durable roofs with greater efficiency and customization options. With its advanced technology, ease of installation, and superior quality, metal roofs are poised to become the roofing material of choice, revolutionizing the architectural landscape for years to come. [Company Name] continues to lead the way, pushing boundaries, and delivering innovation that shapes the future of the construction industry.

Efficient and Durable Roofing Roll Forming Machine for Color Steel Roofs

Title: Cutting-Edge Color Steel Roofing Roll Forming Machine Revolutionizes Roofing IndustryIntroduction:In an era of constant technological advancements, industries are continually seeking innovative solutions to improve their manufacturing processes. The roofing industry is no exception, with the introduction of the cutting-edge Color Steel Roofing Roll Forming Machine paving the way for significant improvements in speed, efficiency, and quality in roof production. Driven by its commitment to engineering excellence, [Company Name], a leading manufacturer of roofing systems, launched this state-of-the-art machine, which is set to revolutionize the roofing industry.Body:1. Overview of the Color Steel Roofing Roll Forming Machine:The Color Steel Roofing Roll Forming Machine represents the culmination of years of research and development by [Company Name]. This advanced machine is engineered to streamline the roofing production process by forming and shaping steel sheets into precise profiles in a highly efficient and automated manner.2. Unprecedented Speed and Efficiency:The Color Steel Roofing Roll Forming Machine boasts unparalleled speed and efficiency, drastically reducing production time and costs. With its advanced features and automated functionality, the machine is capable of producing high-quality, uniform roofing sheets at a rate of [Specify Rate] meters per minute. This incredible speed allows manufacturers to meet tight deadlines, increase productivity, and subsequently enhance their overall profitability.3. Superior Precision and Quality:The stringent quality control standards of the Color Steel Roofing Roll Forming Machine ensure consistent precision throughout the manufacturing process. The machine's automated processes guarantee accurate sheet profiling with minimal wastage. By maintaining precise dimensions and shape, the machine eliminates human errors and ensures high-quality roofing products that conform to industry standards. Additionally, the machine's cutting-edge technology ensures optimal sheet flatness, further enhancing the durability and reliability of the produced roofing materials.4. Versatility and Customization Capabilities:The Color Steel Roofing Roll Forming Machine caters to a wide range of roofing needs, offering manufacturers unparalleled versatility and customization options. With the ability to produce various profiles, including corrugated or trapezoidal sheets, the machine allows manufacturers to meet diverse customer preferences and project requirements. This versatility positions manufacturers for increased success, as they can readily adapt to changing market demands.5. Enhanced Safety and Easy Operation:[Company Name]'s commitment to safety is evident in the design of the Color Steel Roofing Roll Forming Machine. Equipped with advanced safety features, such as emergency stop buttons and protective guards, the machine ensures the well-being of operators and minimizes the risk of accidents. Furthermore, the machine's intuitive interface and user-friendly controls make it easily operable, eliminating the need for extensive training and reducing operator errors.6. Environmental Sustainability:Incorporating sustainable practices into manufacturing processes has become a global imperative, and the Color Steel Roofing Roll Forming Machine holds true to this commitment. By minimizing energy consumption through optimized engine performance and innovative design, this machine significantly reduces carbon emissions. Furthermore, the machine's efficient use of materials, along with its ability to recycle and reuse excess materials, further reduces the environmental footprint of the roofing industry.Conclusion:With the introduction of the Color Steel Roofing Roll Forming Machine, [Company Name] has reaffirmed its position as an industry leader committed to driving innovation in the roofing sector. The machine's unprecedented speed, efficiency, and precision are set to revolutionize the roofing industry, enabling manufacturers to meet increasing customer demands while maintaining superior quality. As the market becomes increasingly competitive, investing in advanced technologies such as this machine will be crucial for companies seeking to stay ahead and embrace a sustainable future.

High-Quality Sheet Rolling Machine for Color Steel Roofing Panels: Efficient and Easy-to-Use This hand-operated rolling machine is a cost-effective and reliable solution for producing color steel sheeting roofing panels. With a powerful motor and hydraulic system, it can process materials up to 1mm thick at a speed of 8m/min. The machine is easy to operate and consumes minimal energy. It comes with all necessary equipment including roll forming, hydraulic cutter, electric control system, product supporter, and more. We have over 12 years of experience in roll forming technology and offer a wide range of equipment for various applications.

Are you in need of a reliable and cost-effective solution for your roofing needs? Look no further than the sheet hand operated rolling machine. This machine is designed for the production of high-quality color steel sheeting roofing panels, and is the perfect solution for those looking for a low-cost, high-efficiency option.One of the key benefits of this machine is its reliability. The machine has been built to withstand heavy and consistent use, making it a great choice for busy roofing businesses. Additionally, the sheet hand operated rolling machine is easy to operate, with an intuitive control system that allows for easy customization of production according to your needs.Another important feature of this machine is its low energy consumption. This not only helps to keep operating costs low, but also makes it an environmentally friendly option for those looking to reduce their carbon footprint.The sheet hand operated rolling machine is also incredibly versatile, capable of producing panels with thicknesses ranging from 0.3mm to 1mm. This makes it a great choice for a range of different roofing applications, from residential homes to commercial buildings.Finally, the machine is constructed to the highest industry standards, with robust components and state-of-the-art technology. This ensures that you are getting a product that delivers on performance and quality, giving you peace of mind that you are making a wise investment in the long-term success of your business.In conclusion, if you are looking for a top-quality solution for your roofing needs, the sheet hand operated rolling machine is the perfect choice. With its low cost, high efficiency, reliability, and easy operation, this machine is sure to exceed your expectations and deliver the high-quality results you need. So don't wait any longer - invest in this state-of-the-art machine today and take your roofing business to the next level!

Advanced Roll Forming Machine for Color Steel Wall Panels: A Breakthrough Technology

Title: Advanced Steel Wall Panel Roll Forming Machine Revolutionizes Construction IndustryIntroduction:In a breakthrough development for the construction industry, a cutting-edge Color Steel Wall Panel Roll Forming Machine has been introduced by an industry-leading company. This technological marvel aims to streamline the process of manufacturing steel wall panels, revolutionizing the way buildings and structures are constructed. With its state-of-the-art features and precision engineering, this roll forming machine promises to enhance efficiency, reduce costs, and facilitate rapid deployment of high-quality steel panels in a variety of construction projects.Advanced Features:The Color Steel Wall Panel Roll Forming Machine incorporates a range of advanced features that make it stand out from traditional manufacturing methods. Equipped with the latest technology, this innovative machine offers unparalleled precision and flexibility in forming steel panels of various shapes and dimensions. Its computerized control system ensures accurate measurements and reduces human errors, resulting in consistently high-quality panels.One of the key advantages of this advanced machine is its ability to efficiently produce steel panels in large quantities. Its robust design and high-speed operation maximize production capacity, thus catering to the ever-increasing demand for steel panels in the construction sector. This not only reduces manufacturing time but also facilitates faster completion of construction projects, leading to improved overall efficiency.The machine's versatile nature allows it to produce steel panels with a wide range of colors and finishes. Its integrated color coating system offers an extensive palette of options, enabling architects and designers to unleash their creativity and customize panels according to their specific project requirements. This flexibility in design contributes to the aesthetic appeal of structures, enhancing their overall visual impact.Moreover, this roll forming machine incorporates intelligent software that enables seamless integration with other manufacturing processes. It can be easily synchronized with robotic systems, stackers, and packaging units, further automating the production process. By minimizing manual intervention, this integration enhances worker safety, increases efficiency, and reduces production costs.Environmental Impact and Sustainability:In an era characterized by growing environmental consciousness, the Color Steel Wall Panel Roll Forming Machine sets new standards for sustainability. By utilizing precise measurements and minimizing material waste, it significantly reduces the amount of scrap generated during the manufacturing process. This not only minimizes environmental impact but also reduces costs associated with material loss, making it a financially viable option for companies.Additionally, the steel panels produced by this roll forming machine boast high strength and durability, contributing to the longevity of constructed structures. Unlike traditional construction materials, these panels are resistant to corrosion, pests, and fire, ensuring the longevity and safety of buildings. This inherent resilience not only enhances the reputation of construction companies but also offers long-term benefits to building owners, making it an attractive investment for both parties.Impact on the Construction Industry:The introduction of the Color Steel Wall Panel Roll Forming Machine marks a significant turning point in the construction industry. Its ability to streamline manufacturing processes, increase production capacity, and reduce costs is expected to have a transformative effect on the sector. With faster turnaround times and improved quality, construction projects are likely to experience enhanced efficiency and higher customer satisfaction levels.Furthermore, by offering flexibility in design and customization, this roll forming machine empowers architects, designers, and construction companies to create visually stunning structures that meet the unique needs and preferences of clients. It opens up new avenues for creativity and innovation, revolutionizing the way buildings are conceived and constructed.Conclusion:In summary, the introduction of the Color Steel Wall Panel Roll Forming Machine represents a significant leap forward in the construction industry. Its advanced features, precision engineering, and sustainability aspects position it as a game-changer. As this innovative machine becomes increasingly adopted in construction projects, it is poised to redefine the standards and possibilities of how structures are built, setting the industry on a path towards greater efficiency, sustainability, and architectural excellence.

Practical Solar Support Forming Machine for Easy Control with Electrical Cabinet

Solar energy has been gaining popularity in recent times as it is a renewable and sustainable energy source that is eco-friendly. This has led to the increasing use of solar panels, which has resulted in the need for solar panel mounting bracket roll forming machines. A Solar Panel Mounting Bracket Roll Forming Machine is a very practical device that is used for manufacturing solar panel mounting brackets.The roll forming machine uses special equipment that is composed of a feed sheet, a roll forming machine, a cutting device, an electrical control cabinet, and hydraulic station. The machine produces high-quality solar panel mounting brackets that are strong and durable. Solar panel mounting brackets are very important because they hold the solar panels in place and keep them secure.LOTOS 2O19 Solar Support Forming Machine is one of the best solar panel mounting bracket roll forming machines in the market. The machine is very easy to control thanks to the electrical controlling cabinet. This means that the user can easily change the production process to suit their specific needs.The LOTOS 2O19 Solar Support Forming Machine is also very efficient, which makes it ideal for mass production. The machine produces solar panel mounting brackets in large quantities within a short period of time, which ensures that there is enough supply to meet the high demand.The machine has a unique design that ensures that it produces high-quality solar panel mounting brackets. The design includes a precision roller and a computer-controlled system that ensures that the brackets are uniform in size and shape. This ensures that the solar panels are securely held in place and do not fall or get damaged.The roll forming machine is composed of high-quality materials that are durable and long-lasting. This means that the machine can be used for many years without experiencing any wear and tear. It is also very easy to maintain, which reduces the overall maintenance cost.The LOTOS 2O19 Solar Support Forming Machine is very versatile, which means that it can be used to produce different types of solar panel mounting brackets. This is because the machine comes with different molds that can be used to produce different sizes and shapes of brackets. This flexibility makes it ideal for use in different types of solar panel projects.In addition to the LOTOS 2O19 Solar Support Forming Machine, the company also produces the Color Steel Solar Mounting Structure Roll Forming Machine. This machine is also used for manufacturing solar panel mounting brackets, but it is different from the LOTOS 2O19 Solar Support Forming Machine.The Color Steel Solar Mounting Structure Roll Forming Machine is designed to produce solar panel mounting brackets made from colored steel. This means that the brackets are not only strong and durable, but they are also aesthetically pleasing. The machine is also very efficient and easy to control, which makes it ideal for mass production.Overall, the use of solar panel mounting bracket roll forming machines has revolutionized the solar panel industry. The LOTOS 2O19 Solar Support Forming Machine and the Color Steel Solar Mounting Structure Roll Forming Machine are two of the best machines in the market. They are efficient, easy to control, and produce high-quality solar panel mounting brackets. As the demand for solar energy continues to grow, the use of such machines will become even more important.

Discover the Efficiency and Quality of Steel Wall Panel Roll Forming Machines

rehensive guide onColor Steel Wall Panel Roll Forming MachineRoll forming is a widely used metalworking technique used to create long, narrow sheets of metal with consistent cross-sections. One of the most popular types of roll forming machines is the color steel wall panel roll forming machine, which is designed to create high-quality, durable panels used in the construction industry.A color steel wall panel roll forming machine typically consists of a variety of components, including a decoiler, a feeding and leveling system, a roll forming system, a cutting system, and a control system. Each component is essential to the overall functioning of the machine, and must be carefully engineered to meet the specific needs of the application.The decoiler is responsible for unwinding the metal coil and feeding it into the roll forming machine. This component must be capable of handling heavy metal coils, and must be designed to maintain consistent tension throughout the entire process.The feeding and leveling system is used to precisely position the metal coil in preparation for the roll forming process. This system helps to ensure that the metal is fed evenly into the machine, preventing jams or other malfunctions.The roll forming system is perhaps the most important component of the color steel wall panel roll forming machine. This system uses a series of rollers to gradually shape the metal into its final form. The rollers can be adjusted according to the desired specifications for the finished product, allowing for extreme precision and consistency.A cutting system is used to cut the finished panels to the appropriate length. This may be accomplished using traditional mechanical cutting techniques, or may be accomplished using a more advanced laser cutting system.Finally, the control system is used to monitor and manage the entire machine. This system ensures that each component is functioning properly, and that the finished product meets the desired specifications.At {}, we are proud to offer a range of highly advanced color steel wall panel roll forming machines. Each of our machines is engineered to meet the specific needs of our customers, and is designed to provide optimal performance and reliability.Our machines are constructed from the highest quality materials, and are built to withstand even the most challenging industrial environments. We also offer a comprehensive service and support network, ensuring that our customers have access to the help they need when they need it.Whether you are looking for a color steel wall panel roll forming machine for a small workshop or a large-scale manufacturing facility, {} has the experience and expertise to provide the right solution. Contact us today to learn more about our products and services, or to request a quote for a custom roll forming machine.

High-Quality Glazed Tile Cold Forming and Color Steel Roofing Tile Making Machine for Metal Roofs

: The Benefits of Metal Roofing TilesMetal roofing tiles have become increasingly popular over the years due to their durability, longevity, and overall appearance. In recent years, metal roofing tiles have also become a popular choice for homeowners who want to upgrade their homes with an affordable, high-quality roofing option.If you're looking for a roofing material that is not only aesthetically pleasing but also high-performing and durable, then metal roofing tiles might be the perfect choice for you. In this blog post, we'll go over some of the benefits of metal roofing tiles and why they could be the right choice for your home.1. Durability and LongevityOne of the most significant advantages of metal roofing tiles is their durability and longevity. Unlike other roofing materials that deteriorate quickly over time, metal roofing tiles are known for their strength and resistance to environmental factors such as rain, snow, and wind.Most metal roofing tiles come with a warranty that lasts for several decades, so you won't have to worry about replacing your roof anytime soon. Furthermore, metal roofing tiles do not warp, crack or rot like traditional roofing materials, and they are not susceptible to pests like termites that can cause significant damage to your home.2. Energy-efficientAnother great advantage of metal roofing tiles is their energy efficiency. Metal roofing tiles work by reflecting sunlight away from your home, which reduces your home's overall temperature and helps you save on energy costs. In the summer, metal roofing tiles can prevent your home from becoming too hot, leading to lower cooling costs.Similarly, in the winter, metal roofing tiles can help insulate your home and retain heat, resulting in lower heating costs. This means that metal roofing tiles can help you save money on your energy bills while also being eco-friendly.3. Aesthetically PleasingBesides being highly functional, metal roofing tiles are also aesthetically pleasing. Metal roofing tiles come in a wide range of colors and styles to match any home design. You can choose from a sleek and modern look to a more traditional and rustic appearance, depending on your preference.Metal roofing tiles also come in different shapes, such as square, rectangular, and even curved, making it easy to create a unique design for your home. Furthermore, unlike other roofing materials, metal roofing tiles will not fade or lose their color over time, making them the perfect choice for homeowners concerned with maintaining their home's visual appeal.4. Ease of MaintenanceFinally, metal roofing tiles are effortless to maintain. Unlike traditional roofing materials that require frequent inspections and repair, metal roofing tiles are low-maintenance and only require minimal upkeep.You can simply hose down your metal roofing tiles periodically to remove any debris or dirt that may have accumulated. Additionally, because metal roofing tiles are durable, you won't have to worry about replacing damaged tiles often.The TakeawayIn conclusion, metal roofing tiles are an excellent roofing option for homeowners looking for a high-quality, long-lasting roofing material. They are eco-friendly, energy-efficient, and aesthetically pleasing, with minimal maintenance required. With all the benefits that metal roofing tiles have to offer, it's no wonder they've become such a popular choice among homeowners.If you're interested in learning more about Color Steel Profile Forming Equipment or Metal Roof Forming Machine Glazed Tile Cold Forming Machin, contact us today. Our experts will be happy to answer any questions you may have!

Advanced Double Layers Color Steel Roll Forming Machine Revolutionizes Manufacturing Process

Double Layers Color Steel Roll Forming Machine Revolutionizes Steel Manufacturing[City], [Date] - In a breakthrough development, a leading steel manufacturing company has introduced a cutting-edge Double Layers Color Steel Roll Forming Machine. This state-of-the-art technology promises to revolutionize the steel production process by significantly enhancing efficiency and quality.The Double Layers Color Steel Roll Forming Machine, developed by [Company Name], employs advanced roll forming techniques to manufacture high-quality colored steel sheets. By utilizing two layers in the roll forming process, this machine can produce double layers of colored steel sheets simultaneously, making it a game-changer in the industry.One of the key advantages of the Double Layers Color Steel Roll Forming Machine is its ability to increase production capacity. With the capability of manufacturing two sheets at the same time, the machine automatically doubles the output, reducing production time and meeting customer demands more effectively.Moreover, this cutting-edge technology enables the manufacturing of customizable steel sheets. The machine allows for easy adjustment of various parameters, such as shape, size, and color, ensuring flexibility and versatility in meeting diverse customer requirements.Another noteworthy feature of the Double Layers Color Steel Roll Forming Machine is its precision and high-quality output. The advanced roll forming technique employed by the machine ensures accurate dimensions, smooth surface finish, and uniform color distribution throughout the sheets. This guarantees a superior product that meets industry standards and satisfies customer expectations.Furthermore, the machine incorporates robust safety measures to protect workers during the manufacturing process. Safety guards, emergency stop buttons, and sensors are installed to ensure a secure working environment, reducing the risk of accidents and injuries.In addition to its remarkable capabilities, the Double Layers Color Steel Roll Forming Machine is designed with energy efficiency in mind. The technology optimizes power consumption, making it a sustainable choice in steel manufacturing. By minimizing energy usage, the machine helps reduce the company's carbon footprint and contributes to a greener future.With the introduction of this cutting-edge technology, [Company Name] reinforces its commitment to innovation and customer satisfaction. By investing in state-of-the-art machinery like the Double Layers Color Steel Roll Forming Machine, the company strengthens its position as a leader in the steel manufacturing industry, offering its clients unmatched quality and efficiency.[Company Name], a renowned manufacturer with an impeccable record, has been serving the steel industry for over [number of years]. With a passion for excellence and a customer-centric approach, the company has gained the trust of numerous clients worldwide.The Double Layers Color Steel Roll Forming Machine is not only a testament to [Company Name]'s dedication to innovation but also to its mission of providing solutions that drive growth and success for its customers. By enabling faster production, customization, and ensuring top-notch quality, the machine becomes an indispensable asset for businesses in the construction, automotive, and other industries that rely on high-quality steel sheets.As word spreads about the Double Layers Color Steel Roll Forming Machine, companies across the steel industry eagerly anticipate its availability and the positive impact it is bound to have on their manufacturing processes. The machine's ability to revolutionize steel production, enhance productivity, and improve overall product quality makes it a highly sought-after technology in today's competitive market.[Company Name]'s revolutionary Double Layers Color Steel Roll Forming Machine is poised to transform the steel manufacturing landscape. With its innovative features, commitment to safety and sustainability, and a track record of excellence, the machine is set to become a hallmark in the industry. Its arrival signifies a new era of efficiency and quality in steel manufacturing, propelling businesses to new heights of success.

Purchase Quality Color Steel Roll Forming Machine for Efficient Production of Roof Panels

for Sale and Roof Panel Roll Forming Machine.Color Steel Roll Forming Machine for Sale: A Guide to Choosing Your Best OptionIf you're running a business that deals with roofing or construction, you know that having the right equipment is crucial to delivering quality finished products to your clients. One equipment that is invaluable in the roofing and construction industry is the Color Steel Roll Forming Machine. This machine allows you to shape and form metal sheets into various roofing styles and designs that will satisfy the needs of your clients.However, choosing the right Color Steel Roll Forming Machine for your business can be challenging, given the numerous options available in the market today. In this blog, we will guide you on how to pick the best Color Steel Roll Forming Machine for sale, and what factors to consider when making your purchase.1. Quality of the MachineThe quality of the Color Steel Roll Forming Machine is critical to its efficiency and longevity. A machine made of high-quality materials will not only produce quality products but will also be durable enough to handle heavy-duty workloads. When you're shopping for a Color Steel Roll Forming Machine, look at the quality of its materials, including the frame, rollers, and other essential components.2. Ease of UseAnother factor to consider when looking for a Color Steel Roll Forming Machine for sale is the ease of use. You want a machine that is not only easy to operate but also easy to maintain and repair. A machine that requires specialized knowledge and skills to run will cost you both time and money. Thus, ensure that the machine you choose has clear instructions and that the supplier provides adequate support and maintenance services.3. Features and CapabilitiesDifferent Color Steel Roll Forming Machines come with varying features and capabilities. Some machines can only produce specific roofing styles and designs, while others offer a more extensive range of options. Consider the types of roofing projects you'll undertake and choose a machine that can produce the designs required for each project. Additionally, consider the speed at which the machine operates to ensure efficient production.4. PricePricing is an essential factor in choosing a Color Steel Roll Forming Machine for sale. While you want a machine that is of high quality and has all the features you need, you also want to ensure that it is affordable. Take time to compare prices from different suppliers, but ensure that the cheaper options do not compromise on the quality and functionality of the machine.Roof Panel Roll Forming MachineApart from the Color Steel Roll Forming Machine, another essential piece of equipment is the Roof Panel Roll Forming Machine. This machine is used to fabricate roof panels made of metals such as aluminum, copper, or steel. Here are a few tips on how to choose the best Roof Panel Roll Forming Machine.1. Material QualityEnsure that the Roof Panel Roll Forming Machine you choose is made of high-quality materials such as cast iron or steel. This will ensure that it can withstand heavy usage and last for long, even with limited maintenance. The material quality also determines the durability of the machine.2. Speed and AccommodationConsider the speed of the Roof Panel Roll Forming Machine and its ability to accommodate different panel sizes. Ensure that the machine can produce your desired panel sizes and designs within a reasonable time frame, especially if you have a high volume of orders.3. User FriendlyThe ease of use of the Roof Panel Roll Forming Machine is a crucial factor to consider. A straightforward machine that comes with instructions and support from suppliers will help you to deliver quality and efficient services.In conclusion, choosing the right Color Steel Roll Forming Machine and Roof Panel Roll Forming Machine can make all the difference in delivering quality roofing and construction products. By taking into account the key factors addressed in this blog, you can make an informed choice that meets the needs of your business and clientele.