- Home

- Blog

- High-Quality Color Steel Roll Forming Machine Factory: Get the Best Equipment for Your Business

High-Quality Color Steel Roll Forming Machine Factory: Get the Best Equipment for Your Business

By:Admin

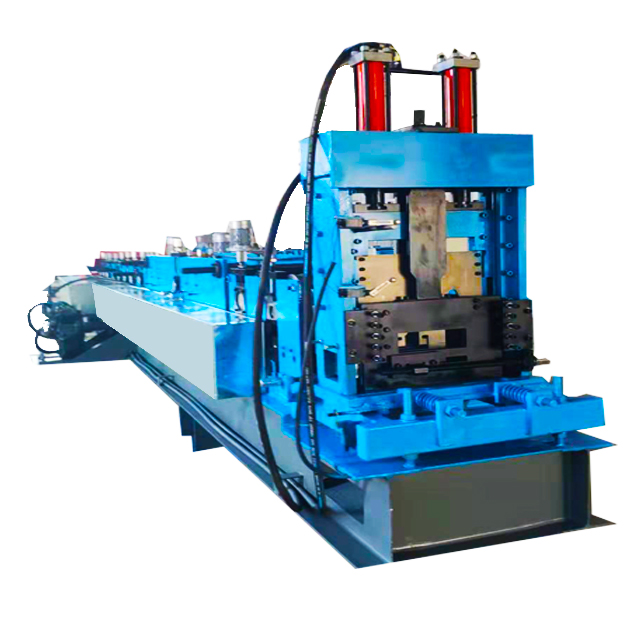

With the rapid development of the construction industry, the demand for color steel roll forming machines has been growing steadily. In response to this trend, the factory has invested heavily in expanding its production capacity and introducing advanced technology to improve the efficiency and quality of its machines. The factory's production line now includes state-of-the-art roll forming machines that are capable of producing various types of color steel building materials with high precision and speed.

The factory's commitment to quality and innovation is reflected in its adherence to strict quality control measures and continuous research and development efforts. The factory's team of engineers and technicians are constantly working on improving the design and performance of their machines to ensure that they meet the highest industry standards. As a result, the factory's roll forming machines are known for their reliability, durability, and efficiency, making them a popular choice among construction companies and contractors worldwide.

In addition to its dedication to quality, the factory is also committed to providing excellent customer service. The factory's team of sales and support staff are well-trained and knowledgeable about the products, and they are always ready to assist clients with any inquiries or technical support they may need. This dedication to customer satisfaction has earned the factory a loyal customer base and a strong reputation in the industry.

The factory's roll forming machines are suitable for producing a wide range of color steel building materials, including roofing sheets, wall panels, and floor decking. The machines are designed to be versatile and easy to operate, making them suitable for both small-scale and large-scale production. Furthermore, the factory also offers customization services, allowing clients to tailor the machines to their specific production requirements.

To further enhance its production capacity and capabilities, the factory has recently added a new production line dedicated to the manufacturing of high-strength color steel materials. This new line is equipped with the latest technology and machinery, allowing the factory to produce stronger and more durable building materials that are well-suited for use in various construction applications.

The factory's commitment to quality, innovation, and customer satisfaction has enabled it to maintain a leading position in the color steel roll forming machine industry. With its expanded production capacity and advanced technology, the factory is well-equipped to meet the growing demand for its products and continue to provide high-quality roll forming machines to clients around the world.

In conclusion, the color steel roll forming machine factory has solidified its position as a leading manufacturer of high-quality roll forming machines for the construction industry. With its expanded production capacity, advanced technology, and commitment to customer satisfaction, the factory is well-positioned to meet the evolving needs of the market and continue to provide innovative solutions for its clients.

Company News & Blog

Color Steel Roll Forming Machine for Single Layer Production

Single Layer Color Steel Roll Forming Machine Revolutionizes the Steel IndustryWith the rapid development of the construction industry, the demand for high-quality and efficient steel roll forming machines has been increasing. In response to this demand, [Company Name] has introduced a cutting-edge Single Layer Color Steel Roll Forming Machine that is set to revolutionize the steel industry.The newly developed Single Layer Color Steel Roll Forming Machine is equipped with advanced technology and state-of-the-art features, making it a game-changer in the production of color steel products. This machine is designed to effectively and efficiently produce single layer color steel roofing and wall panels, meeting the diverse needs of the construction industry.One of the key features of this machine is its precision and accuracy in forming color steel panels. The machine is equipped with high-precision rollers and automated control systems, ensuring the consistency and uniformity of the formed panels. This not only improves the overall quality of the products but also reduces material waste and production costs.Furthermore, the Single Layer Color Steel Roll Forming Machine is highly efficient and capable of producing a large volume of color steel panels in a short amount of time. Its high-speed operation and rapid production capabilities make it an ideal choice for large-scale construction projects and manufacturing facilities.In addition to its efficiency, the machine is also designed for ease of use and maintenance. It features a user-friendly interface and intuitive controls, allowing operators to easily set up and operate the machine with minimal training. Moreover, its durable and robust construction ensures long-term reliability and reduces the need for frequent maintenance.[Company Name] has a long-standing reputation for delivering high-quality and innovative machinery, and the introduction of the Single Layer Color Steel Roll Forming Machine further solidifies its position as a leader in the industry. The company has a team of skilled engineers and technicians dedicated to developing cutting-edge solutions that meet the evolving needs of the steel and construction industries.With its commitment to innovation and quality, [Company Name] aims to set new standards in the steel roll forming machinery market. The Single Layer Color Steel Roll Forming Machine is poised to redefine the production process of color steel panels, providing customers with a cost-effective, reliable, and efficient solution for their manufacturing needs.The introduction of the Single Layer Color Steel Roll Forming Machine comes at a time when the construction industry is experiencing a surge in demand for high-quality and durable color steel products. This machine not only meets this demand but also sets a new benchmark for precision, efficiency, and reliability in steel roll forming technology.In conclusion, the Single Layer Color Steel Roll Forming Machine from [Company Name] is a testament to the company's commitment to innovation and excellence. With its state-of-the-art features and advanced technology, this machine is set to revolutionize the steel industry and become the go-to solution for manufacturers and construction companies seeking high-quality color steel products.

Highly Efficient Metal Profile Forming Equipment Offers Exceptional Quality

Color Steel Profile Forming Equipment: Revolutionizing the Construction IndustryIn recent years, the construction industry has witnessed significant advancements in technology and machinery. One such technological innovation that has revolutionized the industry is the Color Steel Profile Forming Equipment. This state-of-the-art machinery has transformed the way steel profiles are manufactured, improving efficiency and productivity like never before.Color Steel Profile Forming Equipment is a sophisticated machine that is designed to produce high-quality steel profiles with precision and speed. It is commonly used in the manufacturing of roofing, cladding, and façade systems. The equipment is capable of shaping steel sheets into various profiles as per the requirements of the construction project.The process begins by feeding the steel sheet into the machine, where it is then passed through a series of rollers. These rollers exert pressure on the sheet, gradually forming it into the desired profile. The Color Steel Profile Forming Equipment allows for accurate and consistent shaping of the profiles, ensuring that they meet the required specifications.What sets the Color Steel Profile Forming Equipment apart from other similar machinery is its advanced features and capabilities. This equipment utilizes cutting-edge technology to enhance its performance and efficiency. Some of its key features include:1. Automatic Control System: The Color Steel Profile Forming Equipment is equipped with an advanced automatic control system. This system allows for easy programming and monitoring of the machine's operations. It provides real-time information on the status of the equipment, ensuring that it operates smoothly and efficiently.2. High-Speed Production: With the Color Steel Profile Forming Equipment, manufacturers can significantly increase their production capacity. The machine is designed to work at high speeds, ensuring quick and efficient manufacturing of steel profiles. This translates into cost savings and faster project completion times.3. Versatile Profile Options: The Color Steel Profile Forming Equipment offers a wide range of profile options. It can produce profiles of varying sizes, shapes, and designs, catering to the diverse needs of the construction industry. This versatility allows for greater customization and flexibility, enabling architects and designers to bring their visions to life.A company at the forefront of this technological revolution is {}. With their extensive experience and expertise in the construction machinery industry, they have successfully developed and commercialized the Color Steel Profile Forming Equipment. Their commitment to innovation and quality has made them a trusted name in the market.With the Color Steel Profile Forming Equipment, {} has enabled countless construction companies to streamline their operations and achieve higher productivity. The machine's precision and efficiency have garnered praise from customers who have witnessed the significant improvements in their manufacturing processes.Moreover, {} offers comprehensive after-sales services and technical support, ensuring that their customers maximize the benefits of the Color Steel Profile Forming Equipment. They provide training programs and maintenance assistance to help operators and maintenance personnel effectively operate and maintain the machinery.In conclusion, the Color Steel Profile Forming Equipment has emerged as a game-changer in the construction industry. Its advanced features and capabilities have revolutionized the way steel profiles are manufactured, leading to increased efficiency, productivity, and cost savings for construction companies. With companies like {} at the helm, the future of construction machinery looks promising, promising a more technologically advanced and efficient industry.

Practical Solar Support Forming Machine for Easy Control with Electrical Cabinet

Solar energy has been gaining popularity in recent times as it is a renewable and sustainable energy source that is eco-friendly. This has led to the increasing use of solar panels, which has resulted in the need for solar panel mounting bracket roll forming machines. A Solar Panel Mounting Bracket Roll Forming Machine is a very practical device that is used for manufacturing solar panel mounting brackets.The roll forming machine uses special equipment that is composed of a feed sheet, a roll forming machine, a cutting device, an electrical control cabinet, and hydraulic station. The machine produces high-quality solar panel mounting brackets that are strong and durable. Solar panel mounting brackets are very important because they hold the solar panels in place and keep them secure.LOTOS 2O19 Solar Support Forming Machine is one of the best solar panel mounting bracket roll forming machines in the market. The machine is very easy to control thanks to the electrical controlling cabinet. This means that the user can easily change the production process to suit their specific needs.The LOTOS 2O19 Solar Support Forming Machine is also very efficient, which makes it ideal for mass production. The machine produces solar panel mounting brackets in large quantities within a short period of time, which ensures that there is enough supply to meet the high demand.The machine has a unique design that ensures that it produces high-quality solar panel mounting brackets. The design includes a precision roller and a computer-controlled system that ensures that the brackets are uniform in size and shape. This ensures that the solar panels are securely held in place and do not fall or get damaged.The roll forming machine is composed of high-quality materials that are durable and long-lasting. This means that the machine can be used for many years without experiencing any wear and tear. It is also very easy to maintain, which reduces the overall maintenance cost.The LOTOS 2O19 Solar Support Forming Machine is very versatile, which means that it can be used to produce different types of solar panel mounting brackets. This is because the machine comes with different molds that can be used to produce different sizes and shapes of brackets. This flexibility makes it ideal for use in different types of solar panel projects.In addition to the LOTOS 2O19 Solar Support Forming Machine, the company also produces the Color Steel Solar Mounting Structure Roll Forming Machine. This machine is also used for manufacturing solar panel mounting brackets, but it is different from the LOTOS 2O19 Solar Support Forming Machine.The Color Steel Solar Mounting Structure Roll Forming Machine is designed to produce solar panel mounting brackets made from colored steel. This means that the brackets are not only strong and durable, but they are also aesthetically pleasing. The machine is also very efficient and easy to control, which makes it ideal for mass production.Overall, the use of solar panel mounting bracket roll forming machines has revolutionized the solar panel industry. The LOTOS 2O19 Solar Support Forming Machine and the Color Steel Solar Mounting Structure Roll Forming Machine are two of the best machines in the market. They are efficient, easy to control, and produce high-quality solar panel mounting brackets. As the demand for solar energy continues to grow, the use of such machines will become even more important.

Metal Glazed Tile Roll Forming Machine for Color Steel: A Complete Guide

Color Steel Metal Glazed Tile Roll Forming Machine has become the latest addition to the manufacturing capabilities of the renowned company {}. With the introduction of this advanced machinery, the company is set to further solidify its position as a leader in the industry.The Color Steel Metal Glazed Tile Roll Forming Machine is a state-of-the-art piece of equipment that is designed to produce high-quality metal glazed tiles with precision and efficiency. It is equipped with advanced technology and features that enable it to create impeccably formed and finished metal tiles, meeting the highest industry standards.The machine is capable of handling a wide range of materials, including color steel, galvanized steel, and aluminum, making it a versatile and valuable asset for the company. Its ability to produce metal glazed tiles with different profiles and dimensions further adds to its flexibility and appeal.One of the key advantages of the Color Steel Metal Glazed Tile Roll Forming Machine is its high level of automation. This allows for seamless operation and reduces the need for manual labor, thus improving efficiency and productivity. Additionally, the machine is equipped with quick-change systems that enable rapid production changeovers, further optimizing the manufacturing process.Incorporating the Color Steel Metal Glazed Tile Roll Forming Machine into its production line is a testament to the company's commitment to staying at the forefront of technological advancements in the industry. By investing in cutting-edge machinery, the company aims to enhance its capabilities, expand its product offerings, and ultimately better serve its clients.Furthermore, the acquisition of this advanced machinery underscores the company's dedication to quality and precision. The Color Steel Metal Glazed Tile Roll Forming Machine is set to elevate the standard of the company's metal tile production, ensuring that each tile is manufactured with utmost accuracy and consistency.The introduction of the Color Steel Metal Glazed Tile Roll Forming Machine also reflects the company's forward-thinking approach and willingness to adapt to the evolving needs of the market. By embracing new technology and innovation, the company is poised to stay ahead of the competition and fulfill the demands of an ever-changing industry landscape.In addition to its commitment to technological advancement, the company prides itself on its strong emphasis on quality control and customer satisfaction. The implementation of the Color Steel Metal Glazed Tile Roll Forming Machine is a testament to the company's dedication to delivering top-notch products that meet and exceed the expectations of its clients.As a leader in the industry, the company continuously strives to improve its manufacturing processes and provide innovative solutions for its customers. The integration of the Color Steel Metal Glazed Tile Roll Forming Machine is a prime example of this ongoing effort to push the boundaries of excellence and deliver outstanding results.Overall, the introduction of the Color Steel Metal Glazed Tile Roll Forming Machine signifies a new chapter in the company's journey towards manufacturing excellence. With its cutting-edge technology, versatility, and commitment to quality, the machine is set to revolutionize the company's metal tile production and solidify its standing as a frontrunner in the industry.

Revolutionary Technology Takes Color Steel Profile Manufacturing to the Next Level

Color Steel Profile Manufacturing Machine: Revolutionizing the Construction IndustryIn an era where technological innovations continue to transform various industries, the construction sector is not far behind. One such groundbreaking development is the introduction of the Color Steel Profile Manufacturing Machine, a game-changer that has revolutionized the steel manufacturing process. This cutting-edge equipment has not only improved efficiency but has also enhanced product quality, making it a preferred choice for numerous construction projects worldwide.The Color Steel Profile Manufacturing Machine, developed by an industry-leading company specializing in steel manufacturing equipment, has gained tremendous popularity within a short span of time. Founded in [year of establishment], the company has quickly emerged as a frontrunner in this niche market due to their relentless commitment to research and development, customer-centric approach, and dedication to delivering innovative solutions.The color steel profile manufacturing process begins with the raw materials. The machine can work with a range of materials, including galvanized steel, stainless steel, and aluminum, providing flexibility to cater to diverse project requirements. The company's proficiency in material selection and customization allows them to develop profiles that are not only aesthetically pleasing but also durable and resilient, ensuring longevity and resistance to external factors such as corrosion and weather fluctuations.One of the key advantages of the Color Steel Profile Manufacturing Machine is its advanced automation capabilities. This state-of-the-art equipment is equipped with sophisticated sensors, precision controllers, and cutting-edge software, enabling it to operate with minimal human intervention. This reduces the risk of errors, optimizes production time, and enhances overall efficiency. The machine's automated processes also contribute to cost reduction, as it eliminates the need for extensive manual labor.In addition to its automation capabilities, the Color Steel Profile Manufacturing Machine boasts remarkable precision and accuracy in profile creation. The company's team of experienced engineers and technicians ensures that each profile is meticulously designed and manufactured to meet the highest industry standards. The machine's advanced technology enables it to produce profiles with consistent dimensions, sharp edges, and smooth finishes, guaranteeing a flawless final product.Furthermore, the Color Steel Profile Manufacturing Machine prioritizes environmental sustainability. The company's commitment to green manufacturing practices is reflected in the machine's energy-efficient operations. By employing energy-saving technologies and optimizing resource utilization, the machine minimizes its carbon footprint, making it an eco-friendly choice for environmentally conscious construction projects.The versatility of the Color Steel Profile Manufacturing Machine is yet another notable feature. With the ability to produce a wide range of profiles, such as roofing sheets, wall panels, floor decking, and ceiling systems, this equipment caters to the diverse needs of the construction industry. Its adaptability allows architects and builders to bring their creative visions to life, facilitating the realization of unique and striking architectural designs.As the construction industry continues to evolve, the demand for efficient and high-quality steel manufacturing equipment is on the rise. The Color Steel Profile Manufacturing Machine stands at the forefront of this technological leap, offering a myriad of benefits to various stakeholders, including manufacturers, contractors, and end-users. Its advanced features, precision engineering, eco-friendly operations, and versatility make it an indispensable tool for the modern construction industry.In conclusion, the Color Steel Profile Manufacturing Machine is a remarkable innovation that has transformed the steel manufacturing process. With its advanced automation, precision engineering, environmental sustainability, and versatility, this equipment has become an indispensable asset for construction projects worldwide. As the industry evolves, this game-changing machine continues to redefine the future of steel profile manufacturing, offering endless possibilities for architects, builders, and construction companies alike.

Steel Roll Forming Machine for Efficient Production of Color Steel

Color Steel Roll Forming Machine Market to Witness Rapid Growth by 2025The global Color Steel Roll Forming Machine market is expected to witness significant growth over the forecast period. The increasing demand for lightweight, durable, and cost-effective construction materials is driving the market growth. Color steel roll forming machines are specialized equipment used to manufacture color-coated metal sheets, which are widely used in the construction industry for roofing, cladding, and wall panels.One of the key players in the Color Steel Roll Forming Machine market, {insert company name}, is a leading manufacturer of roll forming machines. The company has a strong presence in the global market and is known for its high-quality products and innovative technologies. With a focus on research and development, {insert company name} has been able to offer advanced and efficient roll forming machines to meet the changing requirements of the construction industry.The color steel roll forming machines offered by {insert company name} are designed with precision and are capable of producing high-quality color-coated metal sheets at a fast pace. These machines are highly durable and require minimal maintenance, making them a cost-effective solution for construction companies. The company also provides customization options to meet the specific requirements of its clients, further strengthening its position in the market.The global Color Steel Roll Forming Machine market is driven by the increasing construction activities in developing countries, as well as the growing demand for energy-efficient and sustainable building materials. With the construction industry focusing on reducing carbon footprint and energy consumption, the use of color-coated metal sheets has become a popular choice due to their recyclability and long lifespan.{insert company name} has been at the forefront of this trend, offering color steel roll forming machines that enable the efficient production of high-quality and environmentally friendly construction materials. The company's machines are equipped with advanced technologies that ensure precise and consistent output, meeting the quality standards required by the construction industry.Moreover, the company's commitment to customer satisfaction and after-sales service has contributed to its strong market presence. {insert company name} provides comprehensive training and support to its clients, ensuring the smooth operation and maintenance of its roll forming machines. This has resulted in a loyal customer base and positive word-of-mouth, further enhancing the company's reputation in the market.The global Color Steel Roll Forming Machine market is highly competitive, with several players vying for market share. However, {insert company name} has been able to differentiate itself through its focus on innovation, quality, and customer service. The company's continuous investment in research and development has enabled it to stay ahead of the competition and offer cutting-edge solutions to its clients.Looking ahead, the Color Steel Roll Forming Machine market is expected to witness rapid growth, driven by the increasing demand for sustainable construction materials and the expansion of the construction industry in emerging economies. With its strong market position and commitment to excellence, {insert company name} is well-positioned to capitalize on these opportunities and further strengthen its presence in the global market.

Efficient and Reliable Color Steel Sheet Roll Forming Machine Revolutionizes the Industry

Title: Cutting-Edge Steel Sheet Roll Forming Machinery Revolutionizes the Construction IndustryIntroduction:In an era of rapid technological advancements, the construction industry has witnessed several innovations that have greatly transformed the way buildings are designed and erected. Among these breakthroughs is the recent introduction of the cutting-edge Color Steel Sheet Roll Forming Machine, a revolutionary piece of equipment that promises to enhance the efficiency, accuracy, and sustainability of the construction process. Developed by a leading manufacturing company, this state-of-the-art technology is poised to revolutionize the way steel sheets are formed, offering numerous benefits to the industry.In-Depth Analysis:The Color Steel Sheet Roll Forming Machine represents a significant leap forward in the production of steel sheets, bringing a myriad of advantages that were previously unheard of in traditional manufacturing processes. By utilizing advanced roll forming techniques, this innovative machinery delivers highly customizable and precision-engineered steel sheets, perfectly suited for a wide range of construction applications.The machine's superior design and engineering allow for increased accuracy and consistency in the formation of steel sheets. Computer-controlled operations ensure precise bending, cutting, and shaping of the metal, resulting in standardized, high-quality products. This level of precision helps eliminate costly material wastage due to improper dimensioning, reducing overall project costs for construction companies.Additionally, the Color Steel Sheet Roll Forming Machine enhances production efficiency by automating the sheet formation process. Equipped with a user-friendly interface, operators can easily input the desired specifications into the machine's control panel, allowing for seamless and error-free operations. The automation feature also reduces labor requirements, enabling businesses to reallocate resources more effectively and increase productivity.Furthermore, the machine's compatibility with a wide range of steel materials, including galvanized, pre-painted, and stainless steel, offers further versatility and flexibility in construction applications. This adaptability allows for the creation of steel sheets in various colors, textures, and finishes, meeting the specific aesthetic requirements of different architectural designs.Beyond its immediate impact on the construction industry, the Color Steel Sheet Roll Forming Machine holds great promise for sustainable development. The technology significantly reduces the carbon footprint associated with steel sheet manufacturing by minimizing energy consumption and waste generation. Manufacturers can optimize material usage through efficient cutting methods and recycle excess materials, minimizing environmental impact and promoting a greener future.Moreover, the use of steel sheets produced by this advanced machine contributes to the overall sustainability of building structures. Steel is a highly sustainable material known for its durability, recyclability, and low maintenance requirements. By integrating steel sheets produced through this innovative method, buildings can achieve greater longevity, structural integrity, and energy efficiency, reducing the need for frequent repairs and replacements and decreasing the depletion of natural resources.Conclusion:The advent of the Color Steel Sheet Roll Forming Machine signifies a new era in construction technology, offering unprecedented precision, efficiency, and sustainability. Its introduction sets the stage for significant advancements in the manufacturing of steel sheets, ultimately transforming the way buildings are constructed. With its potential to reduce costs, enhance productivity, and minimize environmental impact, this cutting-edge machinery paves the way for a more sustainable and efficient construction industry.

Buy High-Quality Color Steel Roll Forming Machine for Your Roof Panels

Color Steel Roll Forming Machine: The Ultimate Solution for Roof Panel ManufacturingIn the rapidly evolving construction industry, the demand for durable and efficient roofing materials is ever-increasing. To meet this demand, manufacturers have turned to advanced machinery, such as the Color Steel Roll Forming Machine. In this blog post, we will explore the various aspects of this revolutionary piece of equipment and delve into its features that make it an indispensable tool for roof panel manufacturing. So, let's dive in!What is a Color Steel Roll Forming Machine?A Color Steel Roll Forming Machine is a specialized piece of equipment designed to transform flat, coiled steel into perfectly shaped roof panels. This machine utilizes a series of roller dies, which gradually bend and shape the steel as it passes through. The output is a quality product with uniform dimensions and excellent precision.Why Choose a Color Steel Roll Forming Machine?There are numerous advantages to using a Color Steel Roll Forming Machine for your roof panel manufacturing needs. Let's take a closer look at some of these key benefits:1. High Production Efficiency: The Color Steel Roll Forming Machine has the capability to produce roof panels at a remarkable speed. With automated operations and high line speeds, this machine ensures increased productivity while keeping the labor requirement to a minimum.2. Versatility: These roll forming machines have the flexibility to produce a wide range of roof panel profiles, allowing manufacturers to cater to various project requirements. Whether it's trapezoidal or corrugated profiles, the Color Steel Roll Forming Machine can deliver it all.3. Superior Product Quality: Precision is the name of the game in today's construction industry. With a Color Steel Roll Forming Machine, you can expect exceptional product quality, as it eliminates the inconsistencies that may arise from manual fabrication. The machine ensures correct panel dimensions, precise angles, and consistent bending, resulting in roof panels that are resistant to leaks, deformation, and corrosion.4. Cost-Effective Solution: Investing in a Color Steel Roll Forming Machine can lead to significant cost savings in the long run. By streamlining the manufacturing process and reducing wastage, manufacturers can optimize raw material utilization and minimize labor expenses. Moreover, the high-quality output from this machine reduces repair and maintenance costs for end-users.5. Enhanced Customization: With advanced control systems, a Color Steel Roll Forming Machine allows for easy adjustments to panel dimensions and shapes. This feature gives manufacturers the ability to accommodate customized orders and meet the specific requirements of different projects. Offering tailor-made solutions is crucial to maintaining a competitive edge in the market.Investing wisely in a Color Steel Roll Forming MachineChoosing the right Color Steel Roll Forming Machine can make a significant difference in the success of your roofing material manufacturing venture. To ensure a wise investment, consider the following factors:1. Machine Stability and Durability: Look for a machine constructed with high-quality materials and components for enhanced stability and longevity. A robust frame and reliable power transmission system are key to maintaining consistent performance over time.2. Cutting Mechanism: The roll forming machine should include a precise and efficient cutting mechanism to produce accurate panel lengths. Opt for machines equipped with advanced servo-driven cutting systems for smooth and clean cuts every time.3. Control System: An intuitive and user-friendly control system is crucial for smooth operation and quick programming changes. Ensure that the machine you choose offers excellent control options and is compatible with various computer systems.4. After-Sales Support: The reputation of the manufacturer is equally important. Before making a purchase, research the customer support services provided by the manufacturer. Look for a company that offers comprehensive after-sales support, including training, technical assistance, and spare parts availability.Conclusion:In the competitive world of roof panel manufacturing, a Color Steel Roll Forming Machine is a game-changer. This advanced machinery not only improves production efficiency but also delivers superior product quality, customization options, and cost savings. Investing in a reliable and high-performance Color Steel Roll Forming Machine is an essential step towards staying ahead in the market and satisfying customer demands. So, embrace this cutting-edge technology and elevate your roofing material manufacturing business to new heights!

High-Quality Color Steel Roll Forming Machine Factory: Get the Best Equipment for Your Business

Color steel roll forming machine has been widely used in the construction industry for its efficiency in creating metal building materials. In order to meet the increasing demand for such machines, a leading color steel roll forming machine factory has recently expanded its production capacity and introduced advanced technology to improve its products. The factory, which is located in (need remove brand name)'s (country) district, has been providing high-quality roll forming machines to clients all over the world.With the rapid development of the construction industry, the demand for color steel roll forming machines has been growing steadily. In response to this trend, the factory has invested heavily in expanding its production capacity and introducing advanced technology to improve the efficiency and quality of its machines. The factory's production line now includes state-of-the-art roll forming machines that are capable of producing various types of color steel building materials with high precision and speed.The factory's commitment to quality and innovation is reflected in its adherence to strict quality control measures and continuous research and development efforts. The factory's team of engineers and technicians are constantly working on improving the design and performance of their machines to ensure that they meet the highest industry standards. As a result, the factory's roll forming machines are known for their reliability, durability, and efficiency, making them a popular choice among construction companies and contractors worldwide.In addition to its dedication to quality, the factory is also committed to providing excellent customer service. The factory's team of sales and support staff are well-trained and knowledgeable about the products, and they are always ready to assist clients with any inquiries or technical support they may need. This dedication to customer satisfaction has earned the factory a loyal customer base and a strong reputation in the industry.The factory's roll forming machines are suitable for producing a wide range of color steel building materials, including roofing sheets, wall panels, and floor decking. The machines are designed to be versatile and easy to operate, making them suitable for both small-scale and large-scale production. Furthermore, the factory also offers customization services, allowing clients to tailor the machines to their specific production requirements.To further enhance its production capacity and capabilities, the factory has recently added a new production line dedicated to the manufacturing of high-strength color steel materials. This new line is equipped with the latest technology and machinery, allowing the factory to produce stronger and more durable building materials that are well-suited for use in various construction applications.The factory's commitment to quality, innovation, and customer satisfaction has enabled it to maintain a leading position in the color steel roll forming machine industry. With its expanded production capacity and advanced technology, the factory is well-equipped to meet the growing demand for its products and continue to provide high-quality roll forming machines to clients around the world.In conclusion, the color steel roll forming machine factory has solidified its position as a leading manufacturer of high-quality roll forming machines for the construction industry. With its expanded production capacity, advanced technology, and commitment to customer satisfaction, the factory is well-positioned to meet the evolving needs of the market and continue to provide innovative solutions for its clients.

Highly Efficient Automatic Steel Roll Forming Machine for Color Steel Production

Fully Automatic Color Steel Roll Forming Machine Revolutionizes Industrial Production[Company Name] is proud to introduce the latest innovation in industrial production technology - the Fully Automatic Color Steel Roll Forming Machine. This cutting-edge machine is set to revolutionize the way color steel products are manufactured, providing an efficient and precise solution for companies in the construction and manufacturing industries.Equipped with state-of-the-art technology, the Fully Automatic Color Steel Roll Forming Machine is designed to streamline the production process, enhancing productivity and reducing labor costs. This advanced machine is capable of producing a wide range of color steel products, including roofing, wall panels, and other construction materials, with remarkable speed and accuracy."We are excited to bring this groundbreaking technology to the market," said [spokesperson], CEO of [Company Name]. "The Fully Automatic Color Steel Roll Forming Machine represents a significant step forward in industrial automation, offering our customers a game-changing solution for their production needs."Designed with precision engineering and high-quality components, the Fully Automatic Color Steel Roll Forming Machine ensures consistent and reliable performance. With its user-friendly interface and automated operations, this machine is easy to operate, requiring minimal training for operators.The machine’s innovative design allows for quick and easy setup, minimizing downtime and maximizing production efficiency. Its advanced control system enables real-time monitoring and adjustments, ensuring optimal performance and product quality.In addition to its high-speed production capabilities, the Fully Automatic Color Steel Roll Forming Machine is also versatile in its application. It can accommodate a variety of color steel materials, thicknesses, and profiles, providing flexibility for different production requirements.With its ability to produce high-quality, precision-engineered color steel products at a rapid pace, the Fully Automatic Color Steel Roll Forming Machine offers a competitive advantage to manufacturers seeking to increase their production capacity and meet growing market demands.As a leading provider of industrial machinery and solutions, [Company Name] is dedicated to delivering cutting-edge technologies that empower businesses to thrive in a rapidly evolving marketplace. The introduction of the Fully Automatic Color Steel Roll Forming Machine underscores the company's commitment to innovation and excellence in serving its customers."We are committed to providing our customers with the best-in-class solutions to enhance their production capabilities and drive their business success," [spokesperson] stated. "The Fully Automatic Color Steel Roll Forming Machine is a testament to our relentless pursuit of innovation and our dedication to delivering value to our customers."With its advanced features and unparalleled performance, the Fully Automatic Color Steel Roll Forming Machine is set to become an indispensable asset for businesses engaged in the production of color steel products. Its ability to elevate production efficiency, product quality, and operational cost-effectiveness positions it as a game-changer in the industry.The introduction of the Fully Automatic Color Steel Roll Forming Machine represents a milestone in the evolution of industrial production technology, setting a new standard for precision, speed, and automation. As companies seek to optimize their manufacturing processes and stay ahead of the competition, this innovative machine offers a compelling solution to meet their evolving needs.In conclusion, the Fully Automatic Color Steel Roll Forming Machine from [Company Name] is poised to transform the landscape of industrial production, empowering businesses to achieve new levels of efficiency, quality, and competitiveness. With its remarkable capabilities and potential impact, this innovative machine is set to make a significant and lasting impression on the industry.