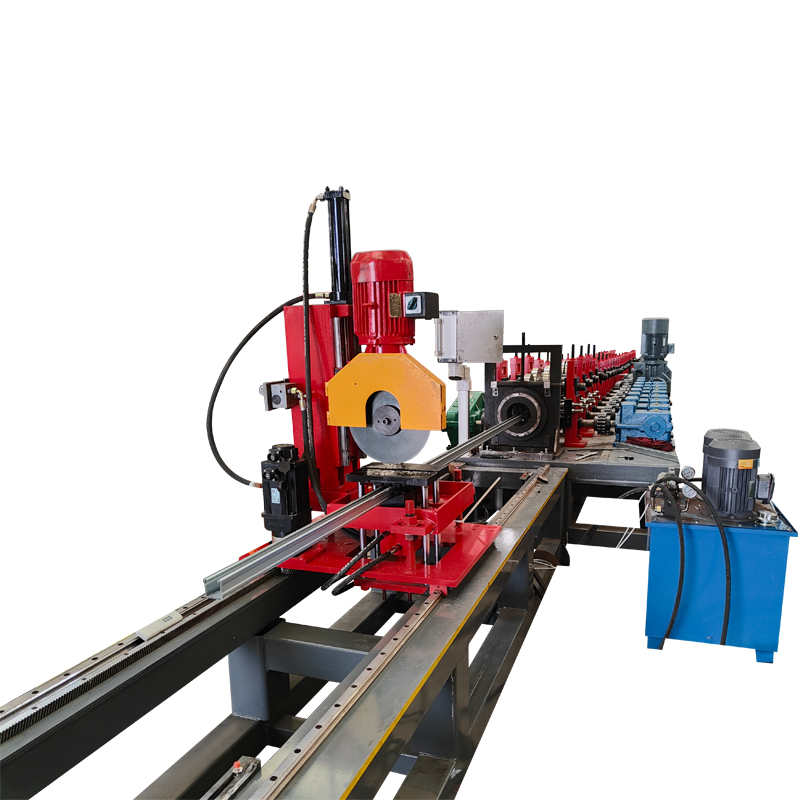

Highly Efficient Automatic Steel Roll Forming Machine for Color Steel Production

By:Admin

[Company Name] is proud to introduce the latest innovation in industrial production technology - the Fully Automatic Color Steel Roll Forming Machine. This cutting-edge machine is set to revolutionize the way color steel products are manufactured, providing an efficient and precise solution for companies in the construction and manufacturing industries.

Equipped with state-of-the-art technology, the Fully Automatic Color Steel Roll Forming Machine is designed to streamline the production process, enhancing productivity and reducing labor costs. This advanced machine is capable of producing a wide range of color steel products, including roofing, wall panels, and other construction materials, with remarkable speed and accuracy.

"We are excited to bring this groundbreaking technology to the market," said [spokesperson], CEO of [Company Name]. "The Fully Automatic Color Steel Roll Forming Machine represents a significant step forward in industrial automation, offering our customers a game-changing solution for their production needs."

Designed with precision engineering and high-quality components, the Fully Automatic Color Steel Roll Forming Machine ensures consistent and reliable performance. With its user-friendly interface and automated operations, this machine is easy to operate, requiring minimal training for operators.

The machine’s innovative design allows for quick and easy setup, minimizing downtime and maximizing production efficiency. Its advanced control system enables real-time monitoring and adjustments, ensuring optimal performance and product quality.

In addition to its high-speed production capabilities, the Fully Automatic Color Steel Roll Forming Machine is also versatile in its application. It can accommodate a variety of color steel materials, thicknesses, and profiles, providing flexibility for different production requirements.

With its ability to produce high-quality, precision-engineered color steel products at a rapid pace, the Fully Automatic Color Steel Roll Forming Machine offers a competitive advantage to manufacturers seeking to increase their production capacity and meet growing market demands.

As a leading provider of industrial machinery and solutions, [Company Name] is dedicated to delivering cutting-edge technologies that empower businesses to thrive in a rapidly evolving marketplace. The introduction of the Fully Automatic Color Steel Roll Forming Machine underscores the company's commitment to innovation and excellence in serving its customers.

"We are committed to providing our customers with the best-in-class solutions to enhance their production capabilities and drive their business success," [spokesperson] stated. "The Fully Automatic Color Steel Roll Forming Machine is a testament to our relentless pursuit of innovation and our dedication to delivering value to our customers."

With its advanced features and unparalleled performance, the Fully Automatic Color Steel Roll Forming Machine is set to become an indispensable asset for businesses engaged in the production of color steel products. Its ability to elevate production efficiency, product quality, and operational cost-effectiveness positions it as a game-changer in the industry.

The introduction of the Fully Automatic Color Steel Roll Forming Machine represents a milestone in the evolution of industrial production technology, setting a new standard for precision, speed, and automation. As companies seek to optimize their manufacturing processes and stay ahead of the competition, this innovative machine offers a compelling solution to meet their evolving needs.

In conclusion, the Fully Automatic Color Steel Roll Forming Machine from [Company Name] is poised to transform the landscape of industrial production, empowering businesses to achieve new levels of efficiency, quality, and competitiveness. With its remarkable capabilities and potential impact, this innovative machine is set to make a significant and lasting impression on the industry.

Company News & Blog

Advanced Roll Forming Machine for Color Steel Wall Panels: A Breakthrough Technology

Title: Advanced Steel Wall Panel Roll Forming Machine Revolutionizes Construction IndustryIntroduction:In a breakthrough development for the construction industry, a cutting-edge Color Steel Wall Panel Roll Forming Machine has been introduced by an industry-leading company. This technological marvel aims to streamline the process of manufacturing steel wall panels, revolutionizing the way buildings and structures are constructed. With its state-of-the-art features and precision engineering, this roll forming machine promises to enhance efficiency, reduce costs, and facilitate rapid deployment of high-quality steel panels in a variety of construction projects.Advanced Features:The Color Steel Wall Panel Roll Forming Machine incorporates a range of advanced features that make it stand out from traditional manufacturing methods. Equipped with the latest technology, this innovative machine offers unparalleled precision and flexibility in forming steel panels of various shapes and dimensions. Its computerized control system ensures accurate measurements and reduces human errors, resulting in consistently high-quality panels.One of the key advantages of this advanced machine is its ability to efficiently produce steel panels in large quantities. Its robust design and high-speed operation maximize production capacity, thus catering to the ever-increasing demand for steel panels in the construction sector. This not only reduces manufacturing time but also facilitates faster completion of construction projects, leading to improved overall efficiency.The machine's versatile nature allows it to produce steel panels with a wide range of colors and finishes. Its integrated color coating system offers an extensive palette of options, enabling architects and designers to unleash their creativity and customize panels according to their specific project requirements. This flexibility in design contributes to the aesthetic appeal of structures, enhancing their overall visual impact.Moreover, this roll forming machine incorporates intelligent software that enables seamless integration with other manufacturing processes. It can be easily synchronized with robotic systems, stackers, and packaging units, further automating the production process. By minimizing manual intervention, this integration enhances worker safety, increases efficiency, and reduces production costs.Environmental Impact and Sustainability:In an era characterized by growing environmental consciousness, the Color Steel Wall Panel Roll Forming Machine sets new standards for sustainability. By utilizing precise measurements and minimizing material waste, it significantly reduces the amount of scrap generated during the manufacturing process. This not only minimizes environmental impact but also reduces costs associated with material loss, making it a financially viable option for companies.Additionally, the steel panels produced by this roll forming machine boast high strength and durability, contributing to the longevity of constructed structures. Unlike traditional construction materials, these panels are resistant to corrosion, pests, and fire, ensuring the longevity and safety of buildings. This inherent resilience not only enhances the reputation of construction companies but also offers long-term benefits to building owners, making it an attractive investment for both parties.Impact on the Construction Industry:The introduction of the Color Steel Wall Panel Roll Forming Machine marks a significant turning point in the construction industry. Its ability to streamline manufacturing processes, increase production capacity, and reduce costs is expected to have a transformative effect on the sector. With faster turnaround times and improved quality, construction projects are likely to experience enhanced efficiency and higher customer satisfaction levels.Furthermore, by offering flexibility in design and customization, this roll forming machine empowers architects, designers, and construction companies to create visually stunning structures that meet the unique needs and preferences of clients. It opens up new avenues for creativity and innovation, revolutionizing the way buildings are conceived and constructed.Conclusion:In summary, the introduction of the Color Steel Wall Panel Roll Forming Machine represents a significant leap forward in the construction industry. Its advanced features, precision engineering, and sustainability aspects position it as a game-changer. As this innovative machine becomes increasingly adopted in construction projects, it is poised to redefine the standards and possibilities of how structures are built, setting the industry on a path towards greater efficiency, sustainability, and architectural excellence.

Practical and User-Friendly Solar Panel Mounting Bracket Roll Forming Machine Revealed in Latest News

In today's ever-evolving world, the need for sustainable and clean energy solutions has become more apparent than ever. Solar power, in particular, has emerged as a viable alternative to traditional energy sources, and as a result, there has been a surge in the demand for solar panels and other related equipment. One such piece of machinery that has gained significant popularity is the Solar Panel Mounting Bracket Roll Forming Machine.The Solar Panel Mounting Bracket Roll Forming Machine, also known as the Solar Support Forming Machine, is an innovative and practical solution designed for the efficient production of solar panel mounting brackets. This machine combines advanced technology with ease of use, ensuring a seamless and hassle-free manufacturing process.One of the key highlights of the Solar Panel Mounting Bracket Roll Forming Machine is its electrical controlling cabinet, which allows for easy control and operation. This feature ensures that even individuals with limited technical knowledge can operate the machine effectively. With just a push of a button, the electrical controlling cabinet enables users to adjust various parameters, such as speed, angle, and length, to meet their specific manufacturing requirements.Furthermore, the Solar Panel Mounting Bracket Roll Forming Machine is characterized by its high precision and accuracy. This machine utilizes a roll forming process, which involves feeding a continuous strip of metal through a series of rollers to gradually shape it into the desired profile. This method ensures consistent results and minimizes material waste, reducing costs and maximizing productivity.The Solar Panel Mounting Bracket Roll Forming Machine is also known for its versatility. It can produce a wide range of solar panel mounting brackets, suitable for various installation scenarios and panel types. Whether it's ground-mounted, roof-mounted, or pole-mounted systems, this machine can meet all project requirements efficiently.Moreover, the Solar Panel Mounting Bracket Roll Forming Machine is manufactured by a reputable company with expertise in the field of roll forming technology. This company, known for its excellence in engineering and manufacturing, is recognized globally for delivering top-quality products and services to its clients. The company's commitment to innovation and customer satisfaction sets it apart from its competitors, making it a trusted and reliable choice for solar panel manufacturers.The adoption of the Solar Panel Mounting Bracket Roll Forming Machine offers numerous benefits to solar panel manufacturers. Its ease of use, coupled with advanced features such as the electrical controlling cabinet, enables manufacturers to streamline their production processes and increase efficiency. This, in turn, translates into enhanced productivity, reduced production costs, and ultimately, improved profitability.Furthermore, the adoption of solar power as an alternative energy source contributes to a cleaner and greener environment. By investing in state-of-the-art machinery like the Solar Panel Mounting Bracket Roll Forming Machine, manufacturers are taking a step towards sustainable growth and promoting the use of renewable energy.In conclusion, the Solar Panel Mounting Bracket Roll Forming Machine is an essential tool for solar panel manufacturers in the pursuit of cleaner and sustainable energy solutions. Its advanced features, ease of use, and precision make it an invaluable asset for any manufacturing facility. By investing in this practical and efficient machine, manufacturers can significantly improve their productivity, reduce costs, and contribute to a greener future.

Roll Forming Machine for Color Steel Production

Title: Advanced Color Steel Roll Forming Machine Revolutionizes the Steel Manufacturing IndustryIntroduction:With an ever-increasing demand for high-quality and sustainable construction materials, the global steel manufacturing industry has witnessed a significant technological advancement. The latest state-of-the-art Color Steel Roll Forming Machine has emerged as a game-changer, enabling efficient and precision-based production of color steel rolls.This groundbreaking technology, developed by a pioneering company committed to innovation and excellence in steel manufacturing, promises to revolutionize the industry. Designed to streamline the production process while reducing costs and enhancing product quality, this advanced roll forming machine is set to reshape the construction landscape.Streamlined Production Process:The Color Steel Roll Forming Machine automates and streamlines the manufacturing process for color steel rolls. It eliminates the need for manual labor, increasing both efficiency and productivity. With its fully automated operation, the machine can consistently produce high-quality, dimensionally accurate steel rolls at a significantly faster rate than traditional methods.Furthermore, this cutting-edge machine incorporates various advanced features such as automatic feeding, precision cutting, and accurate bending, ensuring a flawless end product. Additionally, it offers enhanced flexibility, allowing manufacturers to produce different profiles and sizes of color steel rolls as per customized requirements.Cost Efficiency and Reduced Waste:The Color Steel Roll Forming Machine is equipped with highly efficient energy-saving technologies. By optimizing power consumption and reducing material waste, it offers significant cost savings for manufacturers. The machine's ability to minimize production errors and material wastage ensures that each roll is utilized efficiently, thereby reducing overall expenses.Moreover, the advanced control system in the machine enables real-time monitoring and adjustment of production parameters. This not only enhances operational efficiency but also minimizes the need for manual intervention, further reducing labor costs.Environmental Sustainability:In line with the growing global focus on sustainability, the Color Steel Roll Forming Machine contributes to environmentally friendly manufacturing practices. Its energy-efficient design reduces carbon emissions and lowers the overall environmental footprint of the manufacturing process.Additionally, the machine's high precision and quality control mechanism ensure minimal material wastage, promoting sustainable resource management. By adopting this advanced technology, steel manufacturers can significantly reduce their impact on the environment and contribute to a greener future.Implications for the Steel Manufacturing Industry:The advent of the Color Steel Roll Forming Machine heralds a new era in the steel manufacturing industry. Its introduction is expected to bring about a multitude of benefits for manufacturers, contractors, and end-users alike.For manufacturers, the integration of this advanced technology allows for increased production capacity and reduced operational costs. The ability to produce a wide range of steel roll profiles opens up new market opportunities, catering to diverse customer demands.Contractors and construction firms benefit from the enhanced quality, precision, and efficiency of color steel rolls. These rolls, produced using the roll forming machine, exhibit superior durability, resistance to corrosion, and aesthetic appeal. The higher strength and reduced maintenance of color steel rolls significantly contribute to the longevity and sustainability of construction projects.Conclusion:The Color Steel Roll Forming Machine, developed by a leading company in steel manufacturing, represents a revolutionary leap forward in the industry. Its automated and efficient production process, coupled with cost-saving measures and environmental sustainability aspects, makes it the perfect solution for the evolving construction landscape.As more manufacturers integrate this advanced technology into their production lines, the steel manufacturing industry is poised to witness unparalleled growth and progress. The Color Steel Roll Forming Machine paves the way for a future where high-quality, sustainable, and economically viable construction materials become the norm, supporting the ever-growing infrastructure needs of our global society.

Discover the Efficiency and Quality of Steel Wall Panel Roll Forming Machines

rehensive guide onColor Steel Wall Panel Roll Forming MachineRoll forming is a widely used metalworking technique used to create long, narrow sheets of metal with consistent cross-sections. One of the most popular types of roll forming machines is the color steel wall panel roll forming machine, which is designed to create high-quality, durable panels used in the construction industry.A color steel wall panel roll forming machine typically consists of a variety of components, including a decoiler, a feeding and leveling system, a roll forming system, a cutting system, and a control system. Each component is essential to the overall functioning of the machine, and must be carefully engineered to meet the specific needs of the application.The decoiler is responsible for unwinding the metal coil and feeding it into the roll forming machine. This component must be capable of handling heavy metal coils, and must be designed to maintain consistent tension throughout the entire process.The feeding and leveling system is used to precisely position the metal coil in preparation for the roll forming process. This system helps to ensure that the metal is fed evenly into the machine, preventing jams or other malfunctions.The roll forming system is perhaps the most important component of the color steel wall panel roll forming machine. This system uses a series of rollers to gradually shape the metal into its final form. The rollers can be adjusted according to the desired specifications for the finished product, allowing for extreme precision and consistency.A cutting system is used to cut the finished panels to the appropriate length. This may be accomplished using traditional mechanical cutting techniques, or may be accomplished using a more advanced laser cutting system.Finally, the control system is used to monitor and manage the entire machine. This system ensures that each component is functioning properly, and that the finished product meets the desired specifications.At {}, we are proud to offer a range of highly advanced color steel wall panel roll forming machines. Each of our machines is engineered to meet the specific needs of our customers, and is designed to provide optimal performance and reliability.Our machines are constructed from the highest quality materials, and are built to withstand even the most challenging industrial environments. We also offer a comprehensive service and support network, ensuring that our customers have access to the help they need when they need it.Whether you are looking for a color steel wall panel roll forming machine for a small workshop or a large-scale manufacturing facility, {} has the experience and expertise to provide the right solution. Contact us today to learn more about our products and services, or to request a quote for a custom roll forming machine.

Steel Profile Roll Forming Machine: The Latest Innovation in Metal Construction Technology

Color Steel Profile Roll Forming Machine Revolutionizes the Construction IndustryWith the constant advancement of technology, the construction industry is always on the lookout for new and innovative solutions to improve efficiency and productivity. One such solution is the Color Steel Profile Roll Forming Machine, which has revolutionized the way steel profiles are manufactured for use in construction projects.The Color Steel Profile Roll Forming Machine, developed by a leading machinery manufacturer, is a state-of-the-art piece of equipment that is designed to streamline the process of manufacturing steel profiles. This machine is capable of producing high-quality steel profiles with consistent dimensions and shapes, making it an indispensable tool for construction companies and steel product manufacturers.The machine utilizes advanced roll forming technology, which involves passing a metal strip through a series of rollers to gradually shape it into the desired profile. This process not only ensures precision and accuracy but also allows for high-volume production with minimal waste material. The result is a cost-effective and efficient method of producing steel profiles that meet the exact specifications of construction projects.In addition to its high production capabilities, the Color Steel Profile Roll Forming Machine offers a wide range of customization options, allowing for the creation of unique and complex profiles to meet the diverse needs of the construction industry. This level of flexibility and adaptability sets it apart from traditional manufacturing methods, making it an essential tool for companies seeking to stay competitive in the ever-evolving construction market.Furthermore, the machine is equipped with advanced control systems and automation technology, which significantly reduces the need for manual labor and increases overall production efficiency. This not only saves time and labor costs but also improves workplace safety by minimizing the risk of accidents associated with manual handling of metal materials.The Color Steel Profile Roll Forming Machine is also designed with sustainability in mind, utilizing energy-efficient processes and minimizing material waste. This reflects the manufacturer's commitment to environmental responsibility and aligns with the growing demand for sustainable construction practices.As a global leader in machinery manufacturing, the company behind the Color Steel Profile Roll Forming Machine has a proven track record of delivering high-quality and innovative solutions to the construction industry. With decades of experience and expertise, the company has established itself as a trusted partner for construction companies and steel product manufacturers around the world.Through continuous research and development, the company has consistently pushed the boundaries of what is possible in steel profile manufacturing, and the Color Steel Profile Roll Forming Machine is a testament to their dedication to excellence and innovation.In conclusion, the Color Steel Profile Roll Forming Machine is a game-changer for the construction industry, offering a combination of productivity, precision, customization, and sustainability that is unmatched by traditional manufacturing methods. By investing in this advanced piece of equipment, construction companies and steel product manufacturers can position themselves at the forefront of the industry, meeting the ever-growing demand for high-quality steel profiles in a cost-effective and sustainable manner. This is undoubtedly a milestone that will shape the future of construction.

Color Steel Roll Forming Machine for Single Layer Production

Single Layer Color Steel Roll Forming Machine Revolutionizes the Steel IndustryWith the rapid development of the construction industry, the demand for high-quality and efficient steel roll forming machines has been increasing. In response to this demand, [Company Name] has introduced a cutting-edge Single Layer Color Steel Roll Forming Machine that is set to revolutionize the steel industry.The newly developed Single Layer Color Steel Roll Forming Machine is equipped with advanced technology and state-of-the-art features, making it a game-changer in the production of color steel products. This machine is designed to effectively and efficiently produce single layer color steel roofing and wall panels, meeting the diverse needs of the construction industry.One of the key features of this machine is its precision and accuracy in forming color steel panels. The machine is equipped with high-precision rollers and automated control systems, ensuring the consistency and uniformity of the formed panels. This not only improves the overall quality of the products but also reduces material waste and production costs.Furthermore, the Single Layer Color Steel Roll Forming Machine is highly efficient and capable of producing a large volume of color steel panels in a short amount of time. Its high-speed operation and rapid production capabilities make it an ideal choice for large-scale construction projects and manufacturing facilities.In addition to its efficiency, the machine is also designed for ease of use and maintenance. It features a user-friendly interface and intuitive controls, allowing operators to easily set up and operate the machine with minimal training. Moreover, its durable and robust construction ensures long-term reliability and reduces the need for frequent maintenance.[Company Name] has a long-standing reputation for delivering high-quality and innovative machinery, and the introduction of the Single Layer Color Steel Roll Forming Machine further solidifies its position as a leader in the industry. The company has a team of skilled engineers and technicians dedicated to developing cutting-edge solutions that meet the evolving needs of the steel and construction industries.With its commitment to innovation and quality, [Company Name] aims to set new standards in the steel roll forming machinery market. The Single Layer Color Steel Roll Forming Machine is poised to redefine the production process of color steel panels, providing customers with a cost-effective, reliable, and efficient solution for their manufacturing needs.The introduction of the Single Layer Color Steel Roll Forming Machine comes at a time when the construction industry is experiencing a surge in demand for high-quality and durable color steel products. This machine not only meets this demand but also sets a new benchmark for precision, efficiency, and reliability in steel roll forming technology.In conclusion, the Single Layer Color Steel Roll Forming Machine from [Company Name] is a testament to the company's commitment to innovation and excellence. With its state-of-the-art features and advanced technology, this machine is set to revolutionize the steel industry and become the go-to solution for manufacturers and construction companies seeking high-quality color steel products.

Discover the Latest Innovations in Steel Roll Forming Machines

Color Steel Roll Forming Machine: Empowering the Steel Industry with Efficiency and PrecisionThe manufacturing industry, particularly the steel industry, has been a significant source of growth and prosperity for the economy at large. As the world continues to develop and progress, demands for high-quality steel products continue to rise accordingly. To meet these demands while remaining competitive, businesses, and manufacturers must strive to employ state-of-the-art machinery and equipment. In this vein, the Color Steel Roll Forming Machine, developed by the team at [company name], has revolutionized the industry.The Color Steel Roll Forming Machine has been designed for the efficient and precise production of high-quality steel products. This advanced piece of equipment uses a cold-roll forming process to transform flat sheets of metal into complex shapes and designs with ease. The finished products are durable, and aesthetically pleasing and can be used in various construction and building applications, including roofing, wall and ceiling cladding, and insulation.This innovative industrial machine boasts a range of features that set it apart from traditional roll-forming machines. The machine's advanced software and hardware systems ensure a high degree of accuracy and precision in the forming process. It is equipped with state-of-the-art controls that allow operators to program the machine to produce a wide range of shapes and designs, without requiring manual adjustments for each operation. Further, it has a continuous production process, which eliminates delays, reduces waste, and increases productivity.One significant benefit of using the Color Steel Roll Forming Machine is its versatility. The machine can work with a range of metals, including aluminum, copper, and stainless steel. It can form steel sheets into various profiles, including corrugated, trapezoidal, and tile shapes, making it a versatile and cost-effective solution for businesses that require custom-made steel products.[Company name] is a well-known player in the steel manufacturing industry, providing a broad range of products and services to customers all over the world. Their dedication to producing high-quality products is exemplified in their use of the Color Steel Roll Forming Machine, which has helped them maintain a competitive edge over their rivals.Their machines have been manufactured with the most advanced technology and materials, ensuring precise and reliable performance in demanding manufacturing environments. [Company name] understands that the investment made for such an innovative machine is significant, and in response, they provide ongoing support services to their clients. Their expertise in repair and maintenance guarantees that their customers' machines won't remain idle should any breakdowns occur.The Color Steel Roll Forming Machine has proved to be a game-changer in the steel manufacturing industry. It has reduced the time, resources, and labor required for producing custom products, thereby increasing profitability and efficiency for manufacturers. Moreover, it has enabled manufacturers to meet the ever-increasing demands of customers for high-quality steel products. Notably, the most significant benefit of using this machine is the consistently high-quality products it produces, which meet and exceed industry standards.In conclusion, the Color Steel Roll Forming Machine is an indispensable tool for modern steel manufacturers. Its unique combination of efficiency and precision has revolutionized the steel industry, resulting in higher quality products, increased productivity, and reduced costs. If your business is looking for an innovative solution to steel fabrication, you need to consider incorporating the Color Steel Roll Forming Machine into your operations. With [company name] as your partner, this machine provides an unbeatable solution for all your steel fabrication needs.

Advanced Roll Forming Machine for Corrugated Color Steel Sheets Unveiled in Latest News

Corrugated Color Steel Roll Forming Machine Revolutionizes the Metal Roofing Industry[City Name], [Date] - The metal roofing industry is undergoing a revolutionary change as [Company Name], a leading provider of roll forming machines, unveils their latest innovation – the Corrugated Color Steel Roll Forming Machine. This cutting-edge machinery is set to transform the way metal roofs are manufactured, bringing unprecedented efficiency, durability, and visual appeal to the architectural landscape.Metal roofs have gained immense popularity over the years due to their superior strength, longevity, and energy-efficient properties. However, their market share has been limited by the high production costs, challenges in customization, and time-consuming installation processes. With the introduction of the Corrugated Color Steel Roll Forming Machine, [Company Name] aims to overcome these limitations and propel the metal roofing industry to new heights.The Corrugated Color Steel Roll Forming Machine boasts a multitude of innovative features that make it a game-changer in the field. Designed with precision engineering, it utilizes advanced technology to seamlessly transform flat metal sheets into corrugated panels with intricate patterns and vibrant colors. The machine's automated processes allow for high-speed production, significantly reducing manufacturing time and costs while ensuring consistent quality.One of the standout features of the Corrugated Color Steel Roll Forming Machine is its ability to produce customized metal roof panels on-demand. Architects, contractors, and homeowners can now unleash their creativity and choose from an extensive range of designs, dimensions, and color combinations. This flexibility not only enhances the aesthetic appeal but also opens up new avenues for architectural expression and design innovation.Moreover, [Company Name] has incorporated advanced coating techniques into the machine's operation. The Corrugated Color Steel Roll Forming Machine is equipped with a state-of-the-art color coating system, enabling the application of weather-resistant and high-quality finish to metal roof panels. This not only adds a polished appearance but also enhances the durability and longevity of the roofs, ensuring they withstand harsh weather conditions and resist corrosion over time.In terms of installation, the Corrugated Color Steel Roll Forming Machine streamlines the process, making it faster and more efficient. Its precision-engineered components guarantee accurate panel dimensions, facilitating easy installation and reducing waste material. Additionally, the lightweight nature of the metal roof panels ensures hassle-free transportation and installation, saving time, labor, and costs.With the Corrugated Color Steel Roll Forming Machine, [Company Name] aims to revolutionize the metal roofing industry by combining unparalleled efficiency, durability, and aesthetic appeal. By eliminating the limitations of traditional metal roofing production, this innovation paves the way for the widespread adoption of metal roofs in residential, commercial, and industrial construction projects.As the demand for eco-friendly and sustainable building materials continues to grow, metal roofs have emerged as a top choice. Their versatility, recyclability, and long lifespan make them an ideal alternative to conventional roofing materials such as asphalt shingles. With the Corrugated Color Steel Roll Forming Machine, [Company Name] is at the forefront of delivering innovative solutions that meet the evolving needs of the architectural and construction industries.Looking forward, [Company Name] plans to further enhance the Corrugated Color Steel Roll Forming Machine's capabilities through ongoing research and development. By incorporating advanced technologies, the company aims to expand the range of metal roof profiles and introduce features like energy-efficient coatings and integrated solar panel compatibility.In conclusion, the Corrugated Color Steel Roll Forming Machine is set to transform the metal roofing industry, enabling architects, contractors, and homeowners to achieve stunning and durable roofs with greater efficiency and customization options. With its advanced technology, ease of installation, and superior quality, metal roofs are poised to become the roofing material of choice, revolutionizing the architectural landscape for years to come. [Company Name] continues to lead the way, pushing boundaries, and delivering innovation that shapes the future of the construction industry.

Color Steel Roll Forming Machine: All You Need to Know

Single Layer Color Steel Roll Forming Machine revolutionizes the steel industry with its advanced technology and efficient production capabilities. This innovative machine is set to transform the way steel is manufactured, making the process faster, more economical, and environmentally friendly.The single layer color steel roll forming machine is designed and manufactured by a leading company in the metal forming industry. This company has a long-standing reputation for producing high-quality equipment and machinery that is used in various industries around the world. With years of experience and expertise in the field, this company has developed a roll forming machine that is at the forefront of technological innovation.The single layer color steel roll forming machine is a game-changer in the steel manufacturing industry. Its advanced technology allows for the production of high-quality color steel panels with precision and efficiency. The machine is designed to roll-form steel coils into various profiles and shapes, creating finished products that are ready for use in construction, automotive, and other industrial applications.One of the key features of this machine is its ability to produce color steel panels in a single layer, eliminating the need for multiple layers of material and reducing waste in the production process. This not only makes the manufacturing process more cost-effective but also more environmentally friendly. The machine is also designed to be energy-efficient, further reducing its environmental impact.In addition to its advanced technology, the single layer color steel roll forming machine is also highly versatile. It can be used to produce a wide range of color steel panels, including roofing sheets, wall cladding, and decorative profiles. This versatility makes it an essential piece of equipment for steel manufacturers looking to diversify their product offerings and meet the varying needs of their customers.Furthermore, the machine is designed with user-friendliness in mind. It is equipped with an intuitive control system that allows for easy operation and monitoring of the production process. This ensures that operators can quickly and efficiently produce high-quality color steel panels without the need for extensive training or expertise.The single layer color steel roll forming machine has already garnered attention and praise from industry professionals. Its advanced technology and efficient production capabilities have set a new standard for steel manufacturing, making it a must-have for companies looking to stay ahead of the competition.With its game-changing technology and sophisticated design, the single layer color steel roll forming machine is poised to revolutionize the steel industry. Its advanced capabilities have the potential to streamline production processes, reduce costs, and minimize environmental impact, making it a valuable asset for steel manufacturers around the world.In conclusion, the single layer color steel roll forming machine is set to make a significant impact on the steel industry. Its advanced technology, efficient production capabilities, and user-friendly design make it a game-changer in the manufacturing process. With its potential to revolutionize steel production, this innovative machine is poised to become an essential tool for companies looking to stay competitive in the ever-evolving steel market.

High-quality Color Steel Roll Forming Machine Factory offers top-of-the-line machinery

Color Steel Roll Forming Machine Factory is a leading manufacturer of roll forming machines in the industry. With a strong focus on innovation and quality, the company has carved a niche for itself in the market and has been serving its customers with top-notch products for many years.The factory is equipped with state-of-the-art facilities and a team of highly skilled professionals who are dedicated to delivering superior quality roll forming machines to their clients. The company has a wide range of products including metal roofing machines, wall panel machines, floor decking machines, and many other custom roll forming machines, catering to the diverse needs of its customers.One of the key factors which sets Color Steel Roll Forming Machine Factory apart from its competitors is its commitment to research and development. The company has a strong R&D team that is constantly working on developing new technologies and improving the existing products to meet the ever-changing demands of the market. This has enabled them to stay ahead of the competition and maintain their position as an industry leader.In addition to the quality of their products, the company is also known for its excellent customer service. They take pride in offering personalized solutions to their clients and providing them with the necessary support and guidance throughout their purchase and beyond. This has helped them build a loyal customer base and establish long-term relationships with many of their clients.Furthermore, Color Steel Roll Forming Machine Factory is committed to sustainability and environmental responsibility. The company ensures that their manufacturing processes are as eco-friendly as possible, and they are always on the lookout for ways to reduce their carbon footprint. This not only reflects their concern for the environment but also their dedication to producing high-quality, sustainable products.The company has also expanded its reach to international markets and has built a strong presence in many countries around the world. This has been possible due to their relentless efforts in maintaining the highest standard in their products as well as providing exceptional customer service.As part of their commitment to continuous improvement, Color Steel Roll Forming Machine Factory regularly participates in industry exhibitions and trade shows, showcasing their latest products and technological advancements. This not only helps them stay updated with the latest trends in the market but also provides them with an opportunity to interact with potential clients and partners.The success of Color Steel Roll Forming Machine Factory can be attributed to their core values of integrity, innovation, and customer satisfaction. These values have been the driving force behind their journey towards becoming a leading manufacturer in the roll forming industry.In conclusion, Color Steel Roll Forming Machine Factory continues to set high standards in the roll forming industry, offering top-quality products, outstanding customer service, and a commitment to sustainability. With their strong focus on innovation and their unwavering dedication to excellence, the company is well-positioned to continue its success and maintain its leadership in the industry for many years to come.